Gabatarwar Hardfacing da Kayayyakin Carbide Sa

Gabatarwar Hardfacing da Kayayyakin Carbide Sa

A cikin shekarun da suka gabata hardfacing ya zama batun ci gaba mai zurfi da ya shafi aikace-aikacen sawa masu juriya. Hardfacing, wanda kuma aka sani da "Hardsurfacing", shine aikace-aikacen ginawa ko ƙarafa mai jurewa zuwa wani yanki ta hanyar walda ko haɗawa don tsayayya da ƙura, lalata, zafin jiki, ko tasiri. Shi ne shigar da kauri mai kauri na kayan aiki masu ƙarfi, masu jure lalacewa akan sawa ko sabon farfajiyar abubuwan da ke ƙarƙashin sawa a cikin sabis. Ana amfani da feshin thermal, feshi-fus da hanyoyin walda gabaɗaya don amfani da taurin fuska. Ana iya ajiye irin wannan gami a saman, gefe, ko kawai wurin wani ɓangaren da za a sawa. Adadin walda na iya yin aiki da saman ƙasa da kuma dawo da abubuwan da ke ƙara tsawon rayuwarsu. Welding fasaha ce mai mahimmanci don cika waɗannan buƙatun kuma don amfani da gawa mai ƙarfi. Mahimman abubuwan da aka haɗa kamar masu murƙushewa ana fallasa su ga lalacewa mai nauyi kuma suna buƙatar ingantattun matakan kariya daga ƙasa don guje wa raguwa mai tsada da rage farashi don kayan gyara masu tsada. An aiwatar da wannan tsari a cikin masana'antu da yawa kamar su Siminti, Ma'adinai, Karfe, Petro-chemical, Power, Sugar Rake da Abinci.

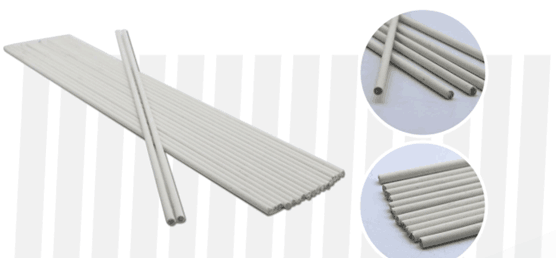

Tungsten carbide yana daya daga cikin mafi wahalar kayan da ake samu don amfanin masana'antu. Ba za a iya narkar da shi da kowane harshen wuta na ƙananan zafin jiki ba. Hakanan yana da ƙarfi sosai. Don dalilai masu wuyar gaske, an murƙushe shi kuma ana amfani da shi tare da haɗin gwiwa tare da ƙarfe "dauri". Barbashin carbide na tungsten galibi ana rufe su a cikin sandar bututun karfe.

ZZBETTER yana da nau'ikan kayan walda da yawa kamar haka:

1.Tungsten Carbide Wear Inserts:

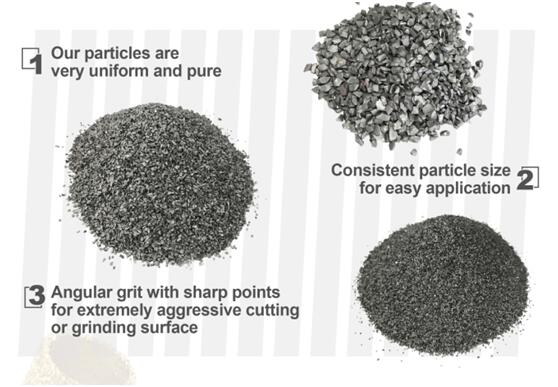

2.Tungsten Carbide Grits: Tungsten carbide grit yana ba da kariya mai ɗorewa mai ɗorewa a cikin wuraren da ke da ƙarancin lalacewa. Ana amfani da shi don kare sassa masu tsada kamar ruwan wulakanci, haƙoran guga, niƙa itace, guduma, haƙoran haƙora, da sauran abubuwan da ake amfani da su iri-iri. Tungsten Carbide grit wata ingantacciyar hanyar kariya ce ta injuna da sassan injina ta hanyar samar da haɓaka mai mahimmanci a cikin tsawon rayuwar waɗannan sassan. Wannan yana rage raguwar lokaci kuma yana rage farashin da ke tattare da sassa marasa kariya.

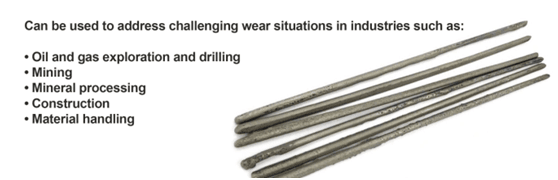

3.Sandunan Haɗe-haɗe tare da Saka Carbide: Waɗannan sanduna masu haɗaɗɗun manyan ayyuka suna amfani da abubuwan da muke sakawa na carbide waɗanda ke ba ku ɓangarorin yankan raɗaɗi masu ƙarfi da ƙarfin da ake buƙata akan mahimman wuraren kayan aikin niƙa.

4.Nickel Carbide Composite Sanduna: Nickel carbide composite sanduna sun kasance masu taurin fuska da gyare-gyaren gyare-gyare da aka yi amfani da su azaman kariyar lalacewa don masu daidaitawa da reamers a cikin masana'antar mai da iskar gas. Manyan pellet na carbide na tungsten suna ba da juriya na abrasion yayin da mafi kyawun pellets suna kare matrix daga lalacewa da yashwa. Matrix na nickel yana ba da juriya mai zafi mai zafi, yana kare jikin bit da ba da izinin gyara kayan yanka da sake amfani da kan haƙora.

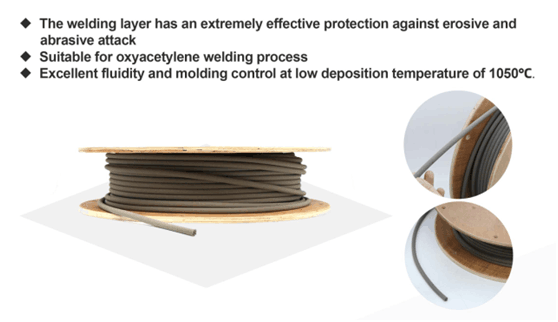

5.Igiyar walda mai sassauƙa: M waldi igiya da aka sanya daga jefa tungsten carbide, mai siffar zobe simintin tungsten carbide ko cakuda biyu a matsayin wuya lokaci, kai-fluxing nickel gami foda ga bonding lokaci, bisa ga wani rabo na gauraye bonding, extrusion gyare-gyare, bushewa, sa'an nan kuma kerarre a kan nickel waya.

6.Nickel Silver Tinning Rods: Nickel silver tinning sanduna su ne janar-manufa oxyacetylene sanduna domin braze waldi iri-iri na ferrous da kuma wadanda ba taferrous karafa, kamar karfe, jefa baƙin ƙarfe, malleable baƙin ƙarfe, da kuma wasu nickel gami. Ana amfani da su da yawa don haɗa walda na tagulla, tagulla, da gami da tagulla da kuma gina abubuwan da suka lalace.

7.Yin Cast Tungsten Carbide Foda: Cast tungsten carbide foda, wanda aka fi sani da W2C, abu ne mai wuyar gaske da ake amfani dashi a aikace-aikace iri-iri. Tare da tsarin eutectic, babban wurin narkewa da taurin, wanda zai iya taimakawa wajen kare kariya da sa kayan juriya. An kera kayandaga cakuda carbon, tungsten da tungsten carbide foda kuma yana da azurfa / launin toka tare da siffa mai kaifi mai kaifi.

8.Tungsten Carbide Pellet Welding Sanduna: Idan aka kwatanta da simintin tungsten carbide foda, tungsten carbide pellets suna da tasiri mafi kyau kuma suna juriya. Yana da halaye na walda na lokaci ɗaya ba tare da reflow soldering ba. Kwayoyin suna da siffar zobe; juzu'i na ƙarami ne, wanda zai iya rage lalacewa da tsada.

Tambaya: Shin taurin kai yana da daraja?

Hardfacing za a iya cika ta amfani da iri-iri matakai, duka a cikin shago da kuma a cikin filin, sa shi sosai m da kuma tsada. Bugu da ƙari, yin amfani da wannan tsari akan sababbin sassa na iya tsawaita rayuwar sabis har zuwa 300%. Duk da haka, idan kun riga kun sawa sassa, zaku iya adana har zuwa 75% tare da farashin maye gurbin.

A ƙarshe, hardfacing shine mafi m tsari don inganta rayuwar da lalacewa bangaren; hardfacing shine mafi kyawun tsarin da aka zaɓa a kwanakin nan don rage farashin maye gurbin; hardfacing yana rage raguwa saboda sassa suna daɗe kuma ana buƙatar ƙarancin rufewa don maye gurbin su; Hardfacing za a iya yi a kan kowane karfe abu ta amfani da fadi da iri-iri na walda matakai.

Idan kuna sha'awar samfuran tungsten carbide kuma kuna son ƙarin bayani da cikakkun bayanai, zaku iya tuntuɓar mu ta waya ko wasiƙa a hagu, ko Aika wasiƙun Amurka a kasan wannan shafin.