Me yasa kuma Yadda ake Weld Carbide Grits akan Sanding Siffar Wuta?

Me yasa kuma Yadda ake Weld Carbide Grits akan Sanding Siffar Wuta?

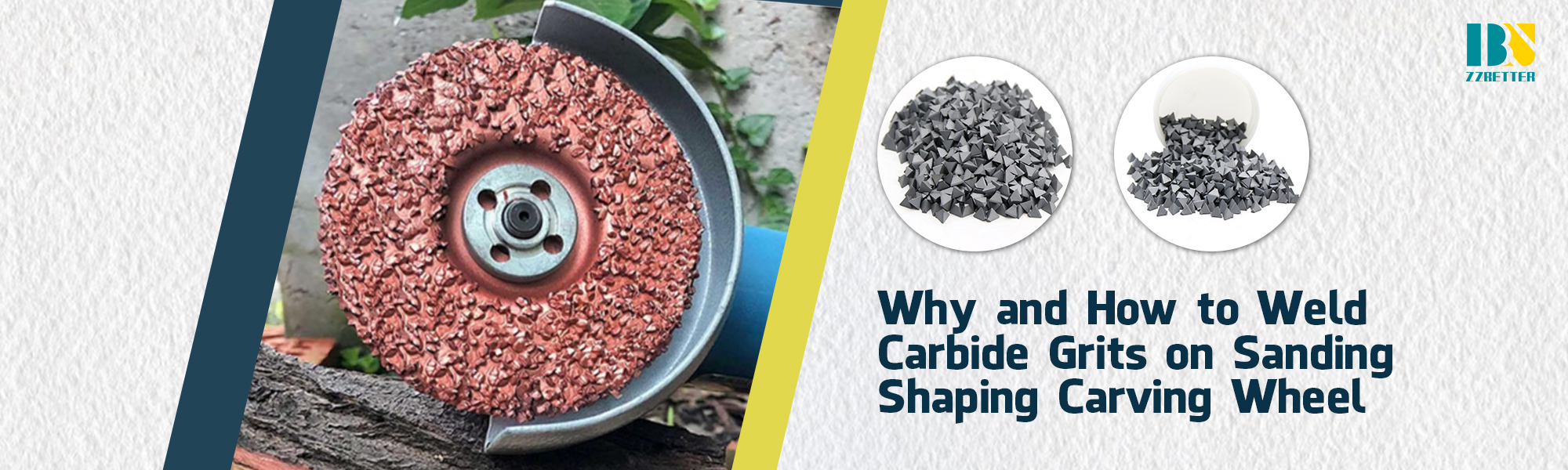

Welding carbide grits akan yashi, siffa, ko keken sassaƙa yana ba da wasu fa'idodi. Carbide abu ne mai wuya kuma mai dorewa, yana sa ya dace da aikace-aikacen abrasive. Lokacin da grits na carbide suna walda su a kan wata dabaran, suna ƙirƙirar ƙasa maras kyau wanda ke da tasiri wajen yanke, niƙa, ko tsara abubuwa daban-daban, kamar itace, ƙarfe, ko dutse.

Gishirin carbide da aka yi wa walda yana ba da ingantaccen aikin yankewa da tsawon rai idan aka kwatanta da ƙafafun abrasive na gargajiya. Suna iya jure yanayin zafi mai girma kuma ba su da saurin lalacewa da sauri. Wannan yana sa su fi dacewa don ayyukan da ke buƙatar cire kayan abu mai nauyi ko amfani mai tsawo.

Anan ga matakan gabaɗayan don walda grits na carbide akan wata dabaran:

1. Zaɓi dabaran da ta dace: Zaɓi dabaran da ta dace da takamaiman aikace-aikacen da kayan da za ku yi aiki da su. Yi la'akari da abubuwa kamar girman dabaran, ƙimar gudu, da dacewa tare da grits na carbide.

2. Shirya dabaran: Tsaftace saman dabaran da kyau don cire duk wani datti, tarkace, ko tsohuwa. Wannan matakin yana tabbatar da kyakkyawan mannewa tsakanin grits na carbide da dabaran.

3. Aiwatar da kayan walda: Dangane da takamaiman hanyar walda da aka yi amfani da ita, ƙila za ku buƙaci amfani da kayan walda ko wakili zuwa saman ƙafafun. Wannan abu yana aiki azaman matsakaici don haɗa grits na carbide zuwa dabaran.

4. Sanya grits na carbide: A hankali sanya grits na carbide akan saman ƙafafun. Ya kamata a daidaita grits a ko'ina kuma a shirya su a cikin tsari ko tsari da ake so.

5. Maganin zafi: Aiwatar da zafi zuwa dabaran don kunna kayan walda da sauƙaƙe tsarin haɗin gwiwa. Ƙayyadadden zafin jiki da tsawon lokacin maganin zafi zai dogara ne akan hanyar walda da kayan da aka yi amfani da su.

6. Bada damar yin sanyi da dubawa: Da zarar aikin walda ya ƙare, ƙyale ƙafafun ya huce. Bincika haɗin kai tsakanin grits na carbide da dabaran don tabbatar da yana da ƙarfi da tsaro. Ya kamata a gyara ko musanya duk wani sako-sako ko mara kyau a haɗe.

Lura cewa ainihin dabarar walda da kayan na iya bambanta dangane da takamaiman kayan aiki da aikace-aikace. Yana da mahimmanci a bi ingantattun ka'idojin aminci da jagororin masana'anta yayin aikin walda don tabbatar da haɗin gwiwa mai nasara da aminci tsakanin grits na carbide da dabaran.

Idan kuna sha'awar Carbide Grits kuma kuna son ƙarin bayani da cikakkun bayanai, zaku iya tuntuɓar mu ta waya ko wasiƙa a hagu, ko Aika wasiƙun Amurka a kasan shafin.