PDC CONICAL CUTTERS FOR HARD ROCK DRILLING

PDC CONICAL CUTTERS FOR HARD ROCK DRILLING

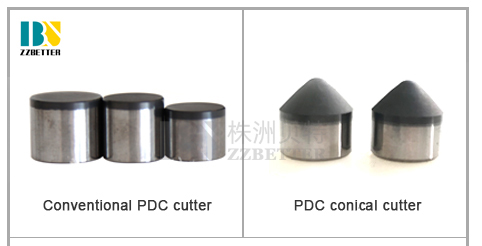

The advent of the Polycrystalline Diamond Compact (PDC) cutter in the mid-1970s started the gradual movement away from the roller cone bit to the shear cutter bit. People want both cutters and bits that can last much longer. Much work has been done on improving diamond formulations, thermal stability, interface strength, and cutter geometry with the overall goal of increasing impact and abrasion resistance. The PDC conical cutters are proved to have better performance in hard rock drilling than conventional shear PDC cutters.

Impact resistance

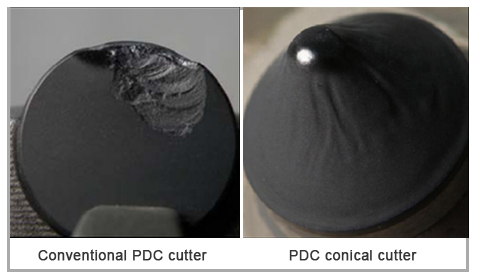

The impact resistance of PDC cutters was tested using a laboratory drop test machine. Drop tests were conducted on the PDC at impact angles between 17 degrees and vertical. Conventional PDC shear cutters were oriented at 10 degrees from the plane of the face. The testing showed that the Conical PDC cutter had 4 to 9 times the impact resistance of a comparably sized shear cutter when dropped onto a WC target. The PDC conical cutter is significantly more resilient to impact loading observed on a bit in the down-hole environment.

VTL Testing

Cutting on a cylindrical log of rock material on a specially instrumented lathe is the common industry method of conducting accelerated wear or abrasion tests on PDC cutters. In this case, a Vertical Turret Lathe was used, rotating a slab of Granite having compressive strength. A fixture holds the PDC and allows the cutter to be brought against the rotating, unconfined rock surface. The Computer Numerical Control (CNC) device controls the depth of cut, rotary speed, linear speed, and feed rate.

Wear resistance.

After PDC cutters gound the granite for a period of time, we can get the wear-off ratio by measuring how many weights are lost. There is mass loss between the PDC cutters and granite. The higher the ratio is, the more wear resistance the PDC cutters will be.

The PDC conical cutter exhibits a significantly high abrasion resistance and successfully cuts hard abrasive rocks with no observable wear, which represents a significant step toward the goal of long-life bits for hard formations in hot environments.

At ZZBETTER, we can offer different types of PDC cutters

If you are interested in tungsten carbide products and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.