What Will Affect Waterjet Focusing Tube?

What Will Affect Waterjet Focusing Tube?

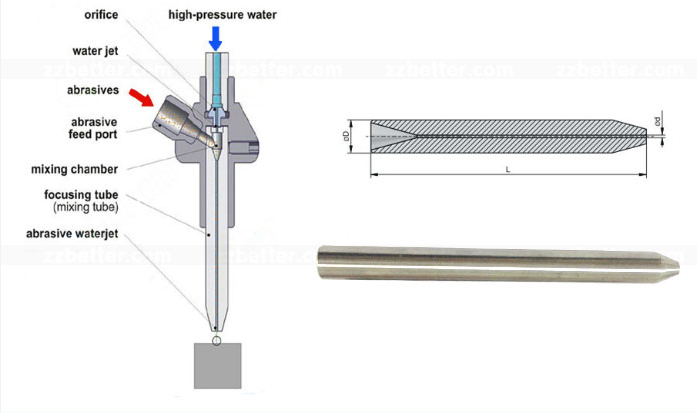

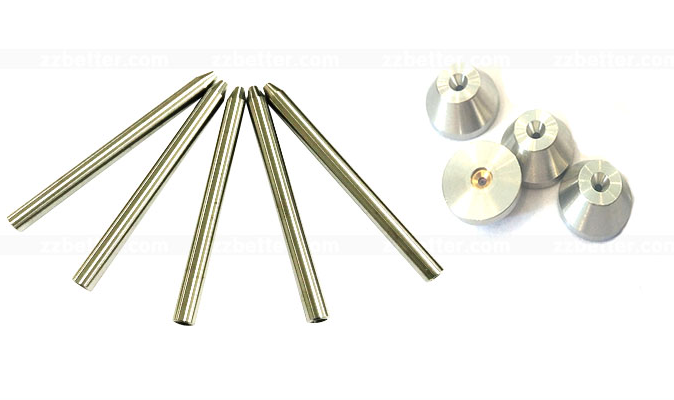

During abrasive waterjet cutting, the water jet focusing tube is a vital component. The high-pressure water and abrasive are focused on an efficient cutting jet tube. In this procedure, the physical processes in the tube crucially affect the final speed and precision of the cutting jet as well as the kerf width at the workpiece. However, which factors influence the function and working life of a waterjet focusing tube?

1. An important feature of a water jet focusing tube is its length. In combination with the geometry of the inlet zone, the waterjet cutting tube length significantly determines the speed and focus of the exiting jet. The pure water jet created by a diamond or sapphire focus orifice is enhanced with an abrasive in the mixing chamber, which is in front of the focusing tube. In this process, both a correct inlet angle and a minimum tube length are necessary to adjust the abrasive particles to the velocity and direction of the water jet, thus, creating a precisely focused and efficient cutting jet. However, the focusing tube should not be too long either, as the jet will then be slowed down due to friction at the inner surface and a decrease in cutting performance.

2. Considering the general interaction of the focusing tube and water orifice, there are also some things to take into account. For example, the proportion of the respective interior diameters is important for the precise focus of the cutting jet. The water jet cutting head guarantees an exact alignment of the focusing nozzle and water jet orifice as well as the right proportion of the respective interior diameter –the advice is a proportion of approx. 1:3. For example, the inner diameter of the waterjet abrasive tube is 1.0mm, and the inner diameter of the orifice should be around 0.3mm. Then this group cutting is the most powerful, and the wear on the water jet tube wall is less.

3. Moreover, the water jet focus tube and orifice have to be exactly aligned. Normally, concentric, slightly wavelike wear can be observed, especially at the tube inlet. If the alignment is imprecise, the wear increases and affects the waterjet nozzle’s quality after a shorter period of use. This may result in a diversion of the cutting jet at the tube outlet and a deterioration of the cut quality at the workpiece.

If you are interested in tungsten carbide products and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.