Main Types of Carbide Burrs

Main Types of Carbide Burrs

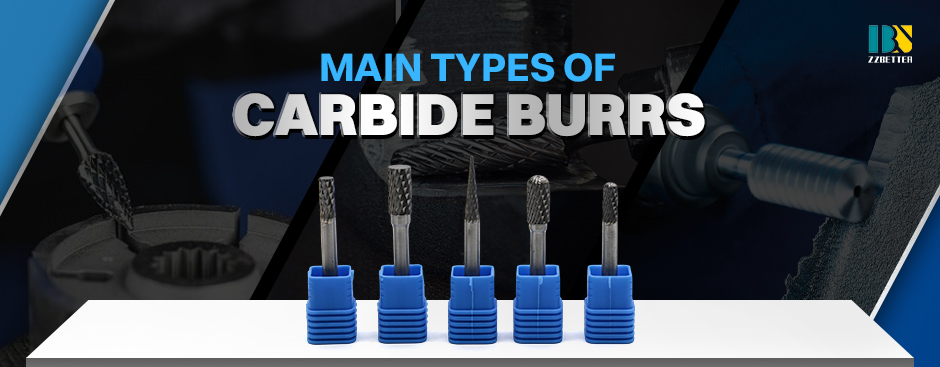

As high-efficiency cutting tools, carbide burrs are widely used in mold processing, automobile manufacturing, aerospace, and other fields due to their high hardness and strong wear resistance. Their classification is based on dimensions such as shape, tooth profile, coating, and application, and different types of burrs play unique roles in processing scenarios.

I. Classification by Shape: Adapting to Different Processing Contours

Classification by shape is the most basic method, mainly including cylindrical, spherical, elliptical, conical, and other types. Cylindrical carbide burrs are suitable for milling of flat surfaces, step surfaces, and groove processing; among them, the straight-groove type has a good chip removal effect, while the spiral-groove type has more stable cutting. Spherical carbide burrs have an arc-shaped head, which is often used for trimming and polishing of curved surfaces and concave arc surfaces. Elliptical carbide burrs combine the characteristics of cylindrical and spherical types, making them suitable for processing complex contours. Conical carbide burrs are mostly used for narrow gaps, inclined surfaces, and chamfering; different tapers are suitable for different processing depths and angles.

II. Classification by Tooth Profile: Matching Processing Precision Requirements

According to tooth profile differences, they can be divided into three categories: coarse teeth, medium teeth, and fine teeth. Coarse-tooth carbide burrs have large tooth pitch and sufficient chip holding space, suitable for rapid material removal in the rough processing stage, such as cleaning of casting burrs and trimming of welded parts. Medium-tooth carbide burrs have moderate tooth profiles, balancing cutting efficiency and processing precision, and are often used for semi-finishing. Fine-tooth carbide burrs have small tooth pitch and dense cutting edges, resulting in low surface roughness, which are suitable for finishing and polishing, especially for mold cavity processing with high surface quality requirements.

III. Classification by Coating: Coping with Different Material Challenges

According to coating types, they can be divided into uncoated, TiN coating, TiAlN coating, and other types. Uncoated carbide burrs have a lower cost and are suitable for processing ordinary metal materials. TiN-coated carbide burrs have higher hardness, with wear resistance improved by more than 30%, suitable for difficult-to-process materials such as stainless steel and high-strength steel. TiAlN-coated carbide burrs have excellent high-temperature resistance, are not easy to wear in high-speed cutting, and are often used for processing special materials such as super alloys and titanium alloys.

IV. Classification by Special Application: Focusing on Specific Scenario Needs

In addition, there are special carbide burrs designed according to special applications, such as special burrs for pipe inner walls, micro burrs for dental restoration, and special-shaped burrs for craft carving. These special types have optimized structures and sizes for specific processing scenarios, further expanding the application scope of carbide burrs.

Clarifying the characteristics and applicable scenarios of various carbide burrs is the key to accurate selection and improvement of processing efficiency and quality, and also lays the foundation for subsequent use and maintenance.