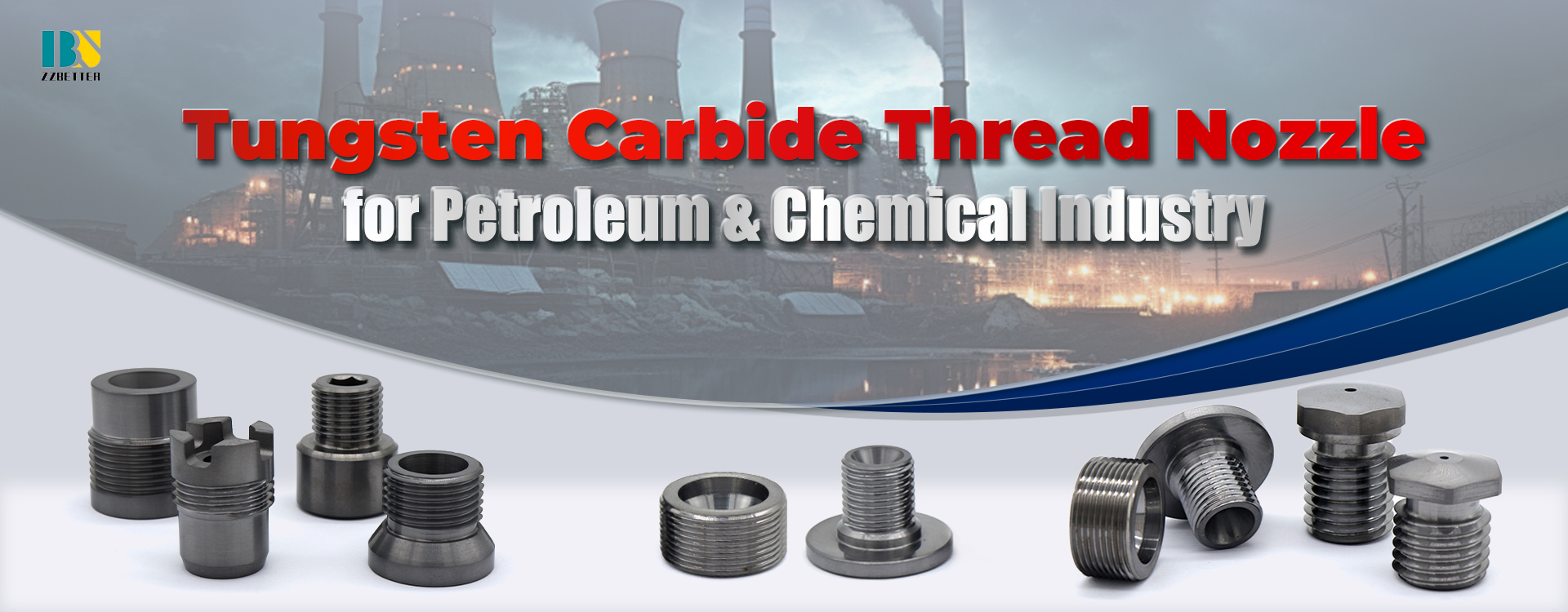

Tungsten Carbide Thread Nozzle for Petroleum & Chemical Industry

Tungsten Carbide Thread Nozzle for Petroleum & Chemical Industry

Introduction

In the petroleum and chemical industries, equipment durability under extreme conditions—such as high-pressure fluid flow, abrasive particles, and corrosive environments—is critical. Tungsten carbide (WC) thread nozzles have emerged as a superior solution, offering unmatched wear resistance, corrosion resistance, and mechanical strength compared to traditional materials like stainless steel or ceramics. This article explores the design, benefits, manufacturing, and applications of tungsten carbide thread nozzles in the oil, gas, and chemical sectors.

1. What is a Tungsten Carbide Thread Nozzle?

A thread nozzle is a precision-engineered component used in fluid control systems to regulate flow direction, pressure, and velocity. When constructed from tungsten carbide, these nozzles exhibit exceptional hardness (1,400–2,200 HV) and durability, making them ideal for harsh industrial environments.

Key Features:

✔ Ultra-High Wear Resistance – Withstands abrasive particles in drilling mud and sand-laden fluids.

✔ Corrosion Resistance – Performs in acidic (H₂S/CO₂) and alkaline conditions.

✔ High-Temperature Stability – Maintains structural integrity up to 1,000°C.

✔ Threaded Design – Ensures secure fitting in high-pressure pipelines.

2. Applications in Petroleum & Chemical Industries

2.1 Oil & Gas Drilling

- Sand Control Nozzles: Used in gravel pack systems to filter sand while maintaining flow.

- Mud Jet Nozzles: Directs high-velocity drilling fluid to clean wellbores.

- Hydraulic Fracturing (Fracking): Resists erosion from proppant-laden fluids.

2.2 Refining & Petrochemical Processing

- Catalyst Injection Nozzles: Prevents wear in FCC (Fluid Catalytic Cracking) units.

- Desulfurization Spray Nozzles: Withstands sulfuric acid exposure.

2.3 Chemical & Power Plants

- High-Pressure Cleaning Nozzles: Used in boiler tube cleaning.

- Corrosive Fluid Dispersion: Resists chemical attack in acid/alkali transfer systems.

3. Why Tungsten Carbide Outperforms Traditional Materials?

Property Tungsten Carbide Stainless Steel (316L) Ceramic (Al₂O₃)

Hardness (HV) 1,400–2,200 200–300 1,500–1,800

Impact Resistance High Moderate Low (Brittle)

Corrosion Resistance Excellent (WC-Ni) Moderate (Pitting) Poor (HF/NaOH)

Max Temperature (°C) 1,000 800 1,600 (Thermal shock-prone)

Advantages:

- 5–10x longer lifespan than steel nozzles in abrasive conditions.

- Reduces downtime by minimizing nozzle replacements.

- Higher flow precision due to minimal erosion-induced deformation.

4. Manufacturing Process of WC Thread Nozzles

4.1 Powder Metallurgy

1. Powder Mixing: WC powder + Co/Ni binder (6–12%).

2. Pressing: Cold isostatic pressing (CIP) for uniform density.

3. Sintering: Vacuum sintering at 1,400–1,500°C for full densification.

4.2 Machining & Threading

- Grinding: Diamond wheel grinding for precision tolerances (±0.01mm).

- Thread Cutting: CNC machining for API/ISO-compliant threads.

4.3 Quality Control

- Ultrasonic Testing: Detects internal cracks.

- Dimensional Inspection: CMM (Coordinate Measuring Machine) verification.

- Hardness & Density Checks: Ensures ≥99.5% theoretical density.

5. Case Study: WC Nozzle in Offshore Drilling

Problem: A North Sea operator faced frequent nozzle failures due to sand erosion (replacement every 2 weeks).

Solution: Switched to WC-13Co threaded nozzles.

Result:

✔ Service life extended to 6+ months

✔ Reduced maintenance costs by 70%

6. Future Trends & Innovations

- Nano-Grained WC: Enhanced toughness for ultra-high-pressure applications.

- 3D-Printed Nozzles: Complex internal geometries for optimized fluid dynamics.

- Smart Nozzles with IoT Sensors: Real-time erosion monitoring.

Conclusion

Tungsten carbide thread nozzles are revolutionizing fluid handling in the petroleum and chemical industries by offering unmatched durability, corrosion resistance, and precision. As technology advances, nano-structured and smart WC nozzles will further enhance efficiency and reduce operational costs.

Interested in upgrading your nozzle systems? Contact our engineering team for a customized solution!

References:

1. API 6A – Wellhead & Christmas Tree Equipment Standards

2. ASTM B777 – Specification for Tungsten Carbide Nozzles

3. Wear Mechanisms in Hard Alloys (Journal of Materials Engineering)