Tsarin Samar da Tsarin Samar da Tsarin Carbide Siminti

Tsarin Samar da Tsarin Samar da Tsarin Carbide Siminti

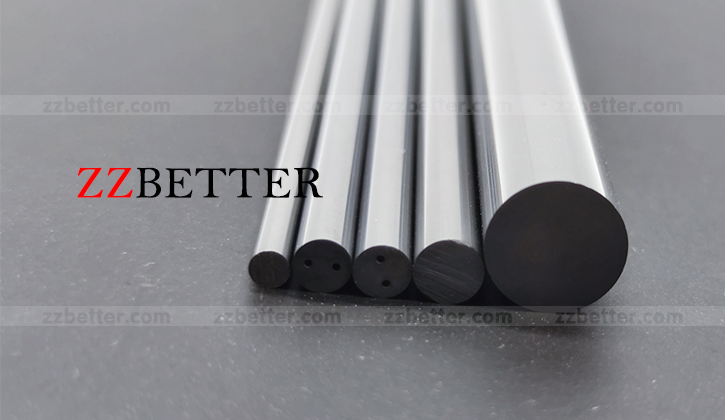

Sandunan carbide da aka yi da siminti sune sandunan carbide da aka yi da siminti. Carbide da aka yi da siminti wani abu ne mai haɗe da wani fili na ƙarfe mai jujjuyawa (lokaci mai wuya) da ƙarfe mai haɗawa (lokacin haɗin gwiwa) wanda aka samar da ƙarfe na foda.

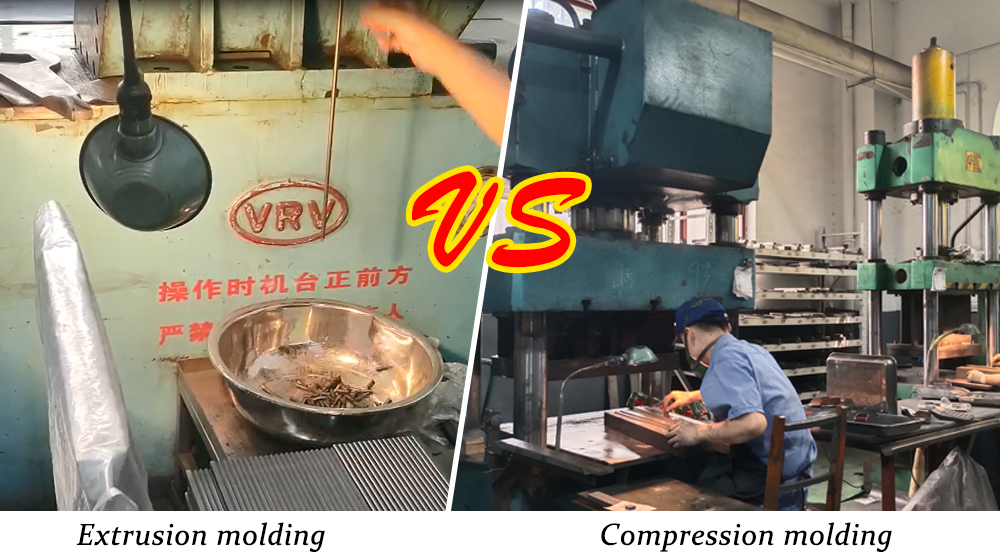

Akwai hanyoyi guda biyu don ƙirƙirar sandunan siminti na carbide. Wata hanya ita ce extrusion forming, wanda shine hanyar da ta dace don samar da sanduna masu tsayi. Irin wannan sandunan siminti na siminti za a iya yanke shi zuwa kowane tsayin da mai amfani yake so yayin aikin fitar da shi. Duk da haka, gaba ɗaya tsawon ba zai iya wuce 350mm ba. Ɗayan ita ce gyare-gyaren matsawa, wanda shine hanya mai dacewa don samar da gajere na mashaya. Kamar yadda sunan ke nunawa, ana matse foda mai siminti a cikin wani tsari.

Alloy abu da aka yi daga refractory karfe da bonding karfe ta foda karfe tsari. Carbide da aka yi da siminti yana da jerin kyawawan kaddarorin irin su babban tauri, juriya mai ƙarfi, ƙarfi mai kyau da tauri, juriya mai zafi, da juriya na lalata. musamman tsananin taurinsa da juriya, wanda ba ya canzawa ko da a zazzabi na 500 ° C, kuma har yanzu yana da tsayin daka a 1000 ° C. Carbide ne yadu amfani da kayan aiki abu, kamar juya kayan aikin, milling cutters, planers, drills, m kayan aikin, da dai sauransu domin yankan Cas baƙin ƙarfe, wadanda ba ferrous karafa, robobi, sinadaran zaruruwa, graphite, gilashin, dutse, da talakawa karfe. kuma ana iya amfani dashi don yankan rigar niƙa na kayan aiki masu wahala kamar ƙarfe mai jure zafi, bakin karfe, ƙarfe mai ƙarfi na manganese, ƙarfe na ƙarfe (niƙa ball, majalisar bushewa, mahaɗin nau'in Z, granulator) --- latsawa. (tare da matsa lamba na'ura mai aiki da karfin ruwa latsa ko extruder) -- - Sintering (degreasing makera, hadedde makera ko HIP low-matsi tanderu)

Danyen kayan ana niƙa ne, a busasshe, a haɗe su da manne bayan an daidaita su, sannan a bushe da kuma rage damuwa bayan an ƙera su ko kuma an fitar da su, sannan kuma ana yin alluran alloy na ƙarshe ta hanyar ragewa da ƙwanƙwasa.

Rashin hasara na zagaye mashaya extrusion samar shi ne cewa samar da sake zagayowar ne dogon. Extrusion na ƙananan sanduna zagaye da ke ƙasa da 3mm, yanke ƙarshen duka biyun zai ɓata wani adadin abu. Tsawon tsayin ƙaramin diamita zagaye mashaya siminti carbide, mafi muni da madaidaiciyar madaidaicin. Tabbas, ana iya inganta matsalolin madaidaiciya da zagaye ta hanyar niƙa cylindrical a mataki na gaba.

Sauran kuma shine gyare-gyaren matsawa, wanda ake amfani da shi don samar da gajerun sanduna. Kamar yadda sunan ke nunawa, akwai wani nau'i wanda ke matse foda mai siminti. Amfanin wannan ciminti carbide mashaya kafa hanya: za a iya kafa a lokaci daya da kuma rage sharar gida. Sauƙaƙe tsarin yanke waya kuma adana busassun busassun busassun hanyar hanyar extrusion. The sama taqaitaccen lokaci zai iya ajiye 7-10 kwanaki ga abokan ciniki.

A taƙaice magana, latsa isostatic shima yana cikin gyare-gyare. Isostatic latsawa shine mafi kyawun tsarin ƙirƙira don samar da manyan sanduna zagaye na carbide masu tsayi. Ta hanyar rufe manyan pistons na sama da na ƙasa, famfo mai matsa lamba yana shigar da matsakaicin ruwa tsakanin babban silinda mai ƙarfi da roba mai matsa lamba, kuma ana ɗaukar matsa lamba ta hanyar roba mai matsa lamba don sanya simintin carbide foda mai latsawa.

Idan kuna sha'awar samfuran carbide tungsten kuma kuna son ƙarin bayani da cikakkun bayanai, zaku iya tuntuɓar mu ta waya ko wasiƙa a hagu, ko Aika wasiƙun Amurka a kasan shafin.