Kula da ingancin masu yankan PDC

Kula da ingancin masu yankan PDC

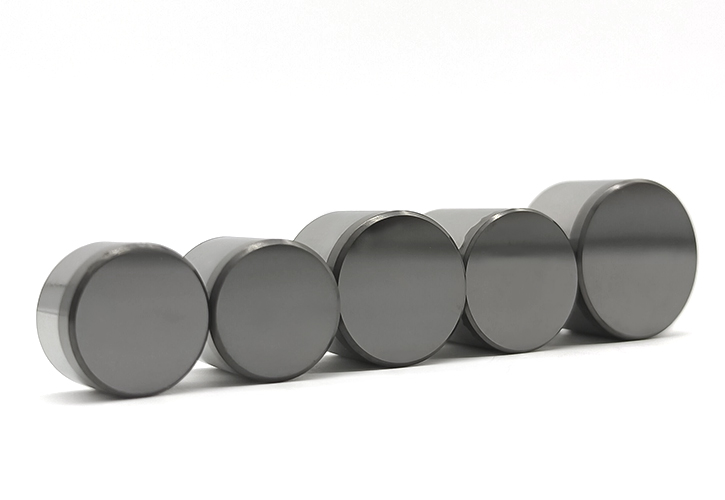

Masu yankan PDC sun ƙunshi polycrystalline Diamond Layer da carbide substrate. Hakanan ana kiran masu yankan PDC suna Polycrystalline Diamond Compact cutters, wanda wani nau'in abu ne mai wuyar gaske. Amfani da maƙallan lu'u-lu'u na polycrystalline (PDC) ya yadu a zamanin yau saboda babban aikinsu da tsayin daka a cikin yanayi mara kyau.

Abubuwan da ke da mahimmanci ga masu yankan PDC a aikace-aikacen hako mai sune inganci da daidaito. Na yi imani kowa zai yarda. Amma yadda za a sarrafa ingancin?

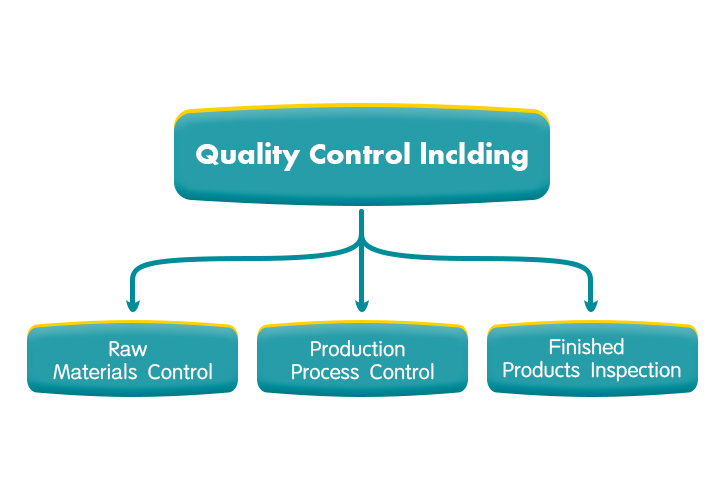

Don tabbatar da kowane yanki na yankan PDC ya zo ZZKYAUhannun abokin ciniki tare da babban inganci, ZZKYAUya kafa tsarin kula da inganci mai tsauri, gami da sarrafa albarkatun ƙasa, sarrafa tsarin samarwa, da sarrafa samfuran ƙãre. Ma'aikacin mu yana da horo sosai kuma yana ƙware sosai kuma mai kwazo. Kowane mai yankan PDC an gina shi tare da ƙwararrun ma'aikata masu horarwa kuma ana sarrafa matsa lamba a cikin latsawa yayin sintering.

PDC cutter ingancin iko:

1. Albarkatun kasa

2. Tsarin samarwa

3. Binciken da aka gama

1. Raw kayan sarrafa

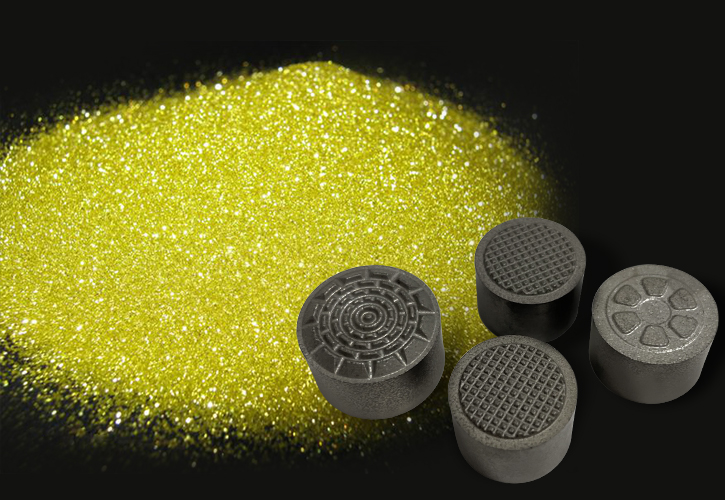

1.1 Don yin aikace-aikacen hako mai na PDC cutter muna amfani da lu'u-lu'u da aka shigo da su. Hakanan dole ne mu murkushe shi kuma mu sake siffata shi, muna sa girman barbashi ya zama iri ɗaya. Hakanan muna buƙatar tsarkake kayan lu'u-lu'u.

1.2 Muna amfani da Laser Barbashi Girman Analyzer don nazarin girman rarrabuwar barbashi, tsafta da girman kowane nau'in foda na lu'u-lu'u.

1.3 Domin tungsten carbide substrate muna amfani da madaidaicin sa tare da juriya mai tasiri.

2. Tsarin samarwa

2.1 Muna da ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun ƙwararrun wurare don samar da masu yanke PDC

2.2 A lokacin samarwa za mu duba yawan zafin jiki da matsa lamba a cikin ainihin lokaci kuma daidaita lokaci. Zazzabi shine 1300-1500℃. Matsakaicin shine 6-7 GPA. Yana latsa HTHP.

Don samar da yanki guda na PDC Cutters zai buƙaci kusan mintuna 30 gabaɗaya.

Ga kowane rukuni na masu yankan PDC, yanki na farko yana da mahimmanci. Kafin samar da taro, za mu bincika yanki na farko don ganin ko ya dace da bukatun abokin ciniki don girma da aiki.

3.Inspection na ƙãre kayayyakin

Don tabbatar da duk masu yankan PDC sun cancanta da daidaito, ya kamata mu ba kawai sarrafa albarkatun albarkatun ƙasa ba da kuma sarrafa kwararar ruwa da haɓaka fasaha, mu ma ya kamata mu himmatu wajen gina dakin gwaje-gwaje tare da wuraren gwaji na ci-gaba don yin koyi da yanayin hako mai da gwada masu yankan PDC a masana'anta. kafin isar da abokan cinikinmu.

Don sarrafa samfurin da aka gama za mu yi daga abubuwan da ke ƙasa:

Girman da duban kamanni

Sarrafa lahani na ciki

Gwajin aiki

3.1 Duban girma da kamanni:diamita, tsawo, lu'u-lu'u kauri, chamfer, geometric masu girma dabam, fashe, baki tabo, da dai sauransu.

3.2 Kula da lahani na ciki

Don sarrafa lahani na ciki za mu yi amfani da ci-gaba da shigo da kayan aikin dubawa na C-san ultrasonic. Don masu yankan PDC da aka shigar da mai dole ne mu bincika kowane yanki.

Tare da tsarin C-scanning, kalaman ultrasonic na iya shiga cikin Layer PDC kuma ya gano lahani ko lahani. Tsarin C-scan na iya gano girman da matsayi na lahani kuma ya nuna su akan allon PC. Zai ɗauki kusan mintuna 20 don bincika lokaci ɗaya.

3.3 Gwajin gwajin aikin PDC Cutter:

sa juriya

tasiri juriya

thermal kwanciyar hankali.

3.3.1 Gwajin Juriya na Saka:ta hanyar auna yawan ma'aunin nauyi da aka rasa bayan masu yankan PDC sun kasa granite a cikin wani ɗan lokaci, muna samun rabon lalacewa. Babban hasara ce tsakanin masu yankan PDC da granite. Mafi girma da rabo, da ƙarin juriya juriya da PDC Cutters za su kasance.

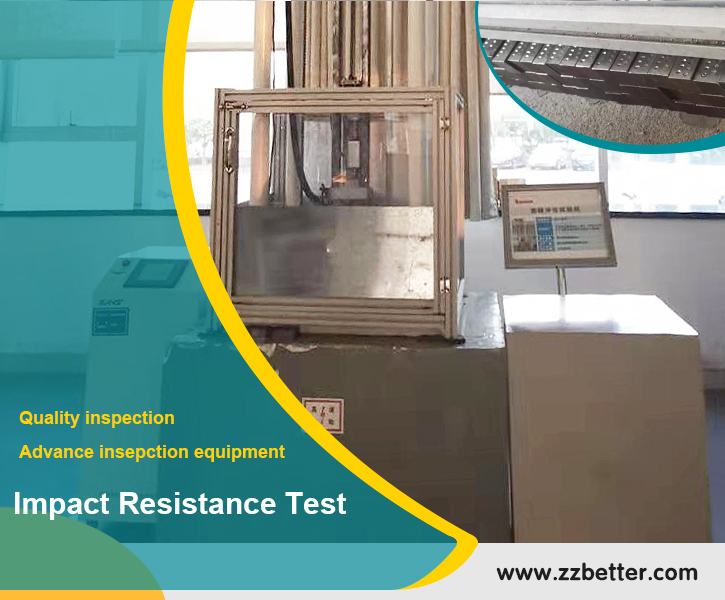

3.3.2TasiriGwajin Juriya:Har ila yau, muna kiransa gwajin Drop-Weight, ta yin amfani da lathe a tsaye a wani tsayin tsayin tsayin daka akan bayanin martabar yankan PDC Cutter, yawanci tare da takamaiman digiri (digiri 15-25). Nauyin wannan lathe a tsaye da tsayin da aka saita nasa zai nuna yadda juriyar wannan abin yankan PDC zai kasance.

3.3.3 Gwajin Kwanciyar Jiki:Ana nufin gwada idan PDC Cutters sun kasance barga mai ƙarfi a ƙarƙashin yanayin aiki mai zafi. A dakin gwaje-gwaje, mun sanya PDC cutters a karkashin 700-750℃a cikin mintuna 10-15 kuma duba yanayin Layer lu'u-lu'u bayan sanyaya yanayi a cikin iska. Yawancin lokaci wannan tsari zai kasance tare da wani juriya na lalacewa da juriya mai tasiri don kwatanta ingancin abin yankan PDC kafin gwaji da kuma bayan gwaji.

Barka da zuwa bi shafin kamfaninmu:https://lnkd.in/gQ5Du_pr

Ƙara koyo:WWW.ZZBETTER.COM