Fasahar Haɓakawa ta Hard Alloy

Fasahar Haɓakawa ta Hard Alloy

Hard gamiwani nau'in abu ne mai wuya wanda ya ƙunshi ƙarfe mai ƙarfi mai ƙarfi da ƙarfe mai ɗaure; Alloys masu wuya, kayan aiki ne masu wuya tare da tsayin daka da tsayin daka, waɗanda aka samar da ƙarfe na foda; saboda kyakkyawan aikinsa, ana amfani da simintin siminti sosai a cikin injina, sassa masu jurewa, ma'adinai, hakowa na ƙasa, hakar mai, sassan injina da sauran fannoni.

Hard Metals Production Technology yana hulɗa da fasahar samarwa da bincike na tsari da kayan aikin injiniya na ƙarfe mai wuya. Ɗaya daga cikin muhimman abubuwa a ci gaban fasaha shine samar da ƙananan ƙarfe na ƙasa. Haɓakawa da ƙaddamar da ƙarafa masu ƙarfi sosai suna tabbatar da cewa yawan aiki zai ƙaru a masana'antar ƙarfe, ma'adinai, mai, da masana'antar kwal.

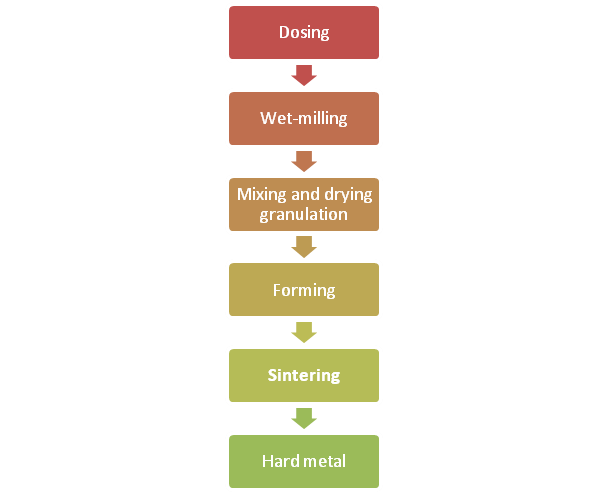

Tsarin samar da simintin carbide kamar haka: shirye-shiryen cakuda, latsawa da kafawa, sintering. Akwai matakai 3 gabaɗaya.

Jadawalin ginshiƙi na tsarin samar da gami mai wuya

Ana auna kayan albarkatun ƙasa da ƙaramin adadin abubuwan da ake buƙata kuma ana ɗora su a cikin injin birgima ko injin motsa jiki. A cikin injin ƙwallon ƙwallon, ana tsabtace albarkatun ƙasa kuma ana rarraba su daidai. Bayan fesa bushewa da kuma girgiza sifting, da cakuda tare da wasu abun da ke ciki da kuma barbashi size bukatun da ake yi don saduwa da bukatun latsa kafa da sintering. Bayan latsawa da sintering, ana fitar da blanks masu wuyar gami kuma an tattara su bayan ingantaccen dubawa.

Hard karfe blanks

Hanyar sarrafa siminti mai kauri:

1. Ciki da waje sarrafa zaren: carbide zaren aiki ya kamata a sarrafa ta zare nika, ba za a iya kai tsaye sarrafa tare da dunƙule famfo.

2. Yin aiki na tsagi na ciki: Ya kamata a zaɓi sandar niƙa lu'u-lu'u, kuma adadin yankan kowane lokaci ana sarrafa shi kusan 20 zuwa 30 um. Ya kamata a yi ƙayyadaddun gyare-gyare bisa ga fa'ida da rashin amfani da sandar niƙa lu'u-lu'u.

3. EDM

4. sarrafa walda: brazing, aikin walda na azurfa

5. Nika aiki: centerless nika, ciki nika, surface nika, kayan aiki nika, da nika dabaran ne kullum lu'u-lu'u nika dabaran, da takamaiman zabi dangane da tsari bukatun.

6. Laser aiki: Laser yankan forming, punching suna samuwa, amma kauri daga cikin yankan yana ƙuntata da ikon Laser inji constraint.

Idan samfurin carbide na tungsten ya zama dusashe ko "girgije", ba kwa buƙatar siyan kayan tsabtace kayan ado mai tsada don haskakawa da goge kayan adon tungsten ɗinku. Cakuda mai sauƙi na ruwan sabulu da kyalle mai tsafta shine kawai abubuwan da kuke buƙata don tsaftace wannan ƙarfe mai ƙarfi, mai jurewa. Har ila yau, siliki carbide ya fi dacewa don kaifi carbide.

Idan kuna sha'awar samfuran tungsten carbide kuma kuna son ƙarin bayani da cikakkun bayanai, zaku iyaTUNTUBE MUta waya ko wasiku a hagu, koAiko da wasikua kasan wannan shafi.