Yadda Kuke cutar da Makin Karshen ku

Yadda Kuke cutar da Makin Karshen ku

Ƙarfe na Carbide suna da juriya mai zafi sosai kuma ana amfani da su don aikace-aikace masu sauri akan wasu kayan aiki mafi wuya kamar simintin ƙarfe, ƙarfe mara ƙarfe, gami, da robobi. Amma ka san cewa rayuwar sabis na mai yankan niƙa zai shafi idan ba a yi amfani da shi yadda ya kamata ba? Anan akwai wasu bangarorin da yakamata ku kula dasu.

1. Dauke da ba daidai ba shafi karshen niƙa.

Carbide karshen niƙa tare da coatings iya ƙara lubricity, da kuma jinkirin halitta kayan aiki lalacewa, yayin da wasu iya ƙara taurin da abrasion juriya. Duk da haka, ba duk suturar sun dace da duk kayan aiki ba, kuma bambancin ya fi bayyana a cikin kayan ƙarfe da na ƙarfe. Misali, abin rufe fuska na Aluminum Titanium Nitride (AlTiN) yana ƙaruwa da ƙarfi da juriya na zafin jiki a cikin kayan ƙarfe amma yana da alaƙa da aluminium, yana haifar da mannewa aiki zuwa kayan aikin yanke. Shafi na Titanium Diboride (TiB2), a gefe guda, yana da ƙarancin kusanci ga aluminum, yana hana haɓakar haɓakawa da tattara guntu, kuma yana haɓaka rayuwar kayan aiki.

2. Yin amfani da tsayin tsayi na yanke a cikin hanyar da ba daidai ba.

Yayin da tsayin tsayin yanke ya zama dole don wasu ayyuka, musamman ma a cikin ayyukan gamawa, yana rage ƙarfi da ƙarfin kayan aikin yanke. A matsayinka na yau da kullum, tsawon yanke kayan aiki ya kamata ya kasance kawai idan dai an buƙata don tabbatar da cewa kayan aiki yana riƙe da yawa na asali na asali kamar yadda zai yiwu. Tsawon tsayin kayan aiki na yanke, yana da sauƙin jujjuya shi ya zama, wanda hakan yana rage tasirin rayuwar kayan aiki da haɓaka damar karyewa.

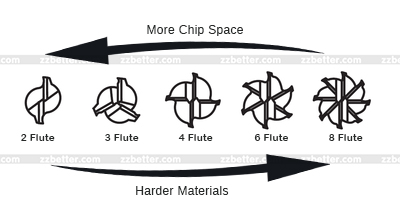

3. Zabar sarewa mara kyau.

Ƙididdigar sarewa na kayan aiki yana da tasiri kai tsaye kuma sanannen tasiri akan ayyukansa da sigogin aiki. Duk da haka, yawan sarewa ba koyaushe ya fi kyau ba. Ana amfani da ƙididdige ƙananan sarewa a cikin aluminum da kayan da ba na ƙarfe ba, wani ɓangare saboda laushin waɗannan kayan yana ba da ƙarin sassauci don ƙara ƙimar cire ƙarfe amma kuma saboda kaddarorin kwakwalwan su. Abubuwan da ba na ƙarfe ba yawanci suna samar da tsayi mai tsayi, guntu masu tsauri, da ƙananan sarewa suna taimakawa rage gyaran guntu. Kayan aikin ƙidayar sarewa galibi suna buƙata don ƙarin kayan ƙarfe, duka don ƙara ƙarfinsu kuma saboda gyaran guntu ba shi da damuwa tunda waɗannan kayan galibi suna samar da ƙananan kwakwalwan kwamfuta.

Mun ƙware a samar muku da ingantattun injinan ƙarshen carbide kuma muna tallafawa sabis ɗin isar da sauri na duniya don odar ku.

Idan kuna sha'awar masana'antar ƙarfe na tungsten kuma kuna son ƙarin bayani da cikakkun bayanai, zaku iya tuntuɓar mu ta waya ko wasiƙa a hagu, ko aika wasiƙun Amurka a kasan shafin.