Nau'in Maɓallin Tungsten Carbide da Wasu Nasiha

TirinOf TungstenCsabaniBmaganaAnd SomeTip

Nau'in maɓallan carbide tungsten sune:

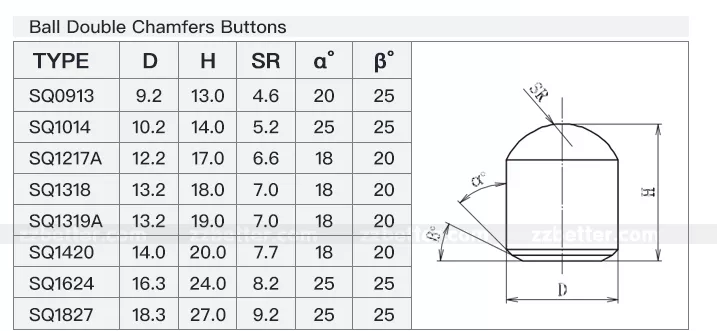

1.Maɓallan Sikeli

Maɓallin kewayawa don saita guduma dutsen, DTH da raƙuman mazugi don rijiyoyin mai a cikin sifofin dutse masu wuyar gaske.

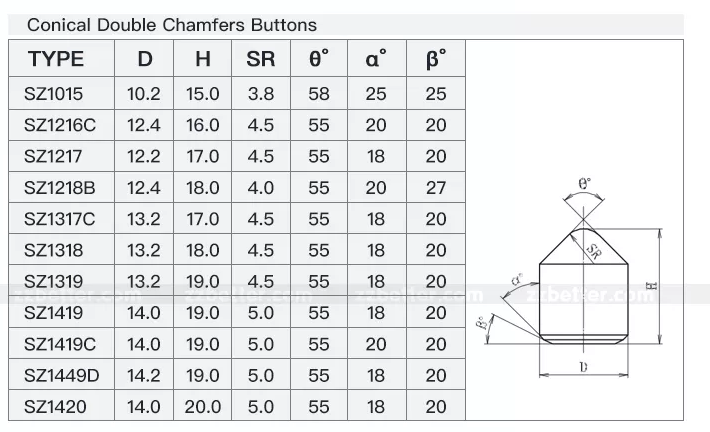

2.Maɓallan conical na Carbide

Maɓallin maɓalli don saka raƙuman haƙar dutse, DTH da raƙuman mazugi, wanda ya dace da ƙirar dutsen matsakaici.

3. Maɓallan harsashi

Maɓallin harsashi don saka DTH da raƙuman mazugi na mazugi, wanda ya dace da ƙirar dutse mai wuya.

Lebur saman hakora, dace da abin nadi mazugi ragowa, lu'u-lu'u rago, stabilizers rami, da dai sauransu, rage karfe surface lalacewa.

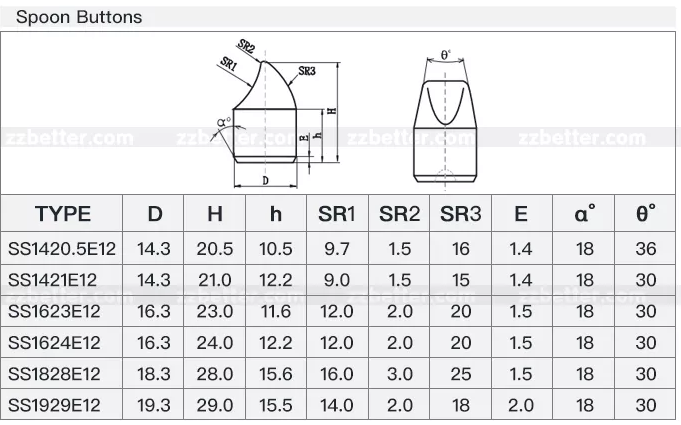

4. Maɓalli mai siffar cokali

Maɓalli mai siffar cokalidon shigar da raƙuman mazugi don hakowa mai tsayi a cikin sifofin dutse masu laushi.

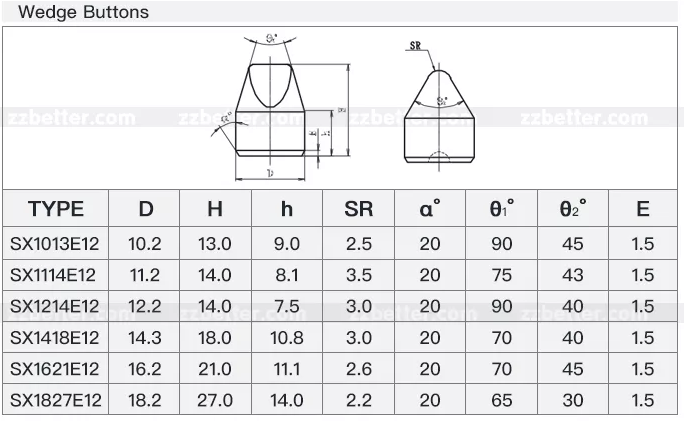

5.Maɓallin Maɓalli

Maɓallai masu siffa mai wutsiya, waɗanda aka yi amfani da su don shigar da ɗigon DTH masu siffa na musamman da raƙuman mazugi na abin nadi, wanda ya dace da ƙirar dutse mai laushi tare da babban ROP da ƙananan hakora masu karye.

Maɓallin simintin carbide da aka ambata a sama na siffofi daban-daban suna da nau'ikan amfani da halayensu na aiki. Wani nau'in maɓalli na siminti ya kamata a yi amfani da shi bisa ga gwajin kuma zaɓi madaidaicin maɓalli na simintin carbide daidai da ainihin halin da ake ciki.

Madaidaicin amfani da maɓallin carbide

A cikin aiwatar da madaidaicin amfani da maɓallan carbide na siminti, ya kamata a kula da waɗannan abubuwan:

1. Don't treat it casually because of wear resistance. Any drill bit needs to monitor its use at any time. Once abnormality is found, if it is repaired in time, the carbide button drill bit is no exception. We must always pay attention to whether it has "cracking" phenomenon or peeling. When this happens, it means that the wear of the drill affects its use, and it needs to be repaired. When the rock drilling speed of the rock drill drops significantly, we should also consider that it may be due to excessive wear of the drill.

2. Bai kamata a yi amfani da karfi ba yayin aikin. Ya kamata a rage ƙarfin motsa jiki don rage damuwa na maɓalli na carbide. A lokaci guda kuma, ya kamata a yi amfani da ruwa mai yawa don zazzagewa don cire dattin da aka haifar yayin aikin cikin lokaci. Haka kuma a kula da amfani da ruwa mai tsafta, a ci gaba da wanke-wanke, sannan a fara aikin da wuri idan ana aiki kawai, idan ba haka ba, zai sa zafin na’urar ya tashi, sai a gamu da ruwa ya huce. haifar da fasa.

ZZBETTER yana da cikakken kewayon siminti na ƙwallon ƙwallon ƙwallon carbide, kuma ana iya samar da maɓallan ma'adinan ma'adinai na siminti daban-daban kuma ana iya keɓance su.