Me yasa Sandunan Carbide suke samun yabo daga abokan cinikinmu?

Me yasa Sandunan Carbide suke samun yabo daga abokan cinikinmu?

1. Foda Madalla.

Muna amfani da 100% budurwa kayan foda don sandunan carbide don duk daidaitattun maki don masana'antar sandar carbide.

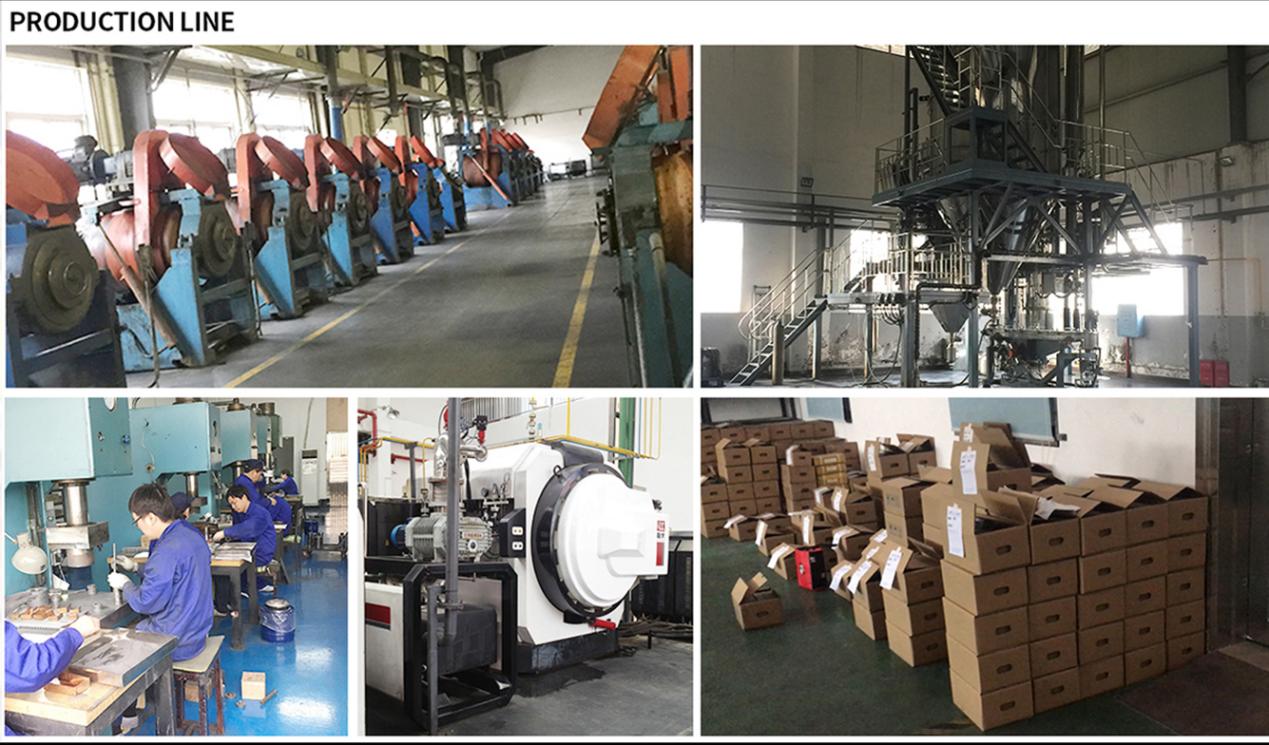

2. Na'urorin samar da ci gaba

Hasumiyar fesa

Ana amfani da hasumiya mai bushewa da bushewar siminti da aka yi da siminti, kuma saboda a cikin nau'in feshi ne, gabobin gabobin sun fi kama.

Farashin HIP

Ana amfani da tanderun HIP masu sarrafa kwamfuta na ci gaba daga Jamus don samar da ƙarin matsin lamba yayin aikin sintiri don samun tsari mai yawa.

Gwajin taurin tungsten carbide

Carbide da aka yi da siminti ƙarfe ne wanda zai iya nuna bambanci a cikin kayan aikin injiniya a cikin abubuwan sinadaran, tsarin nama, da hanyoyin magance zafi. Sabili da haka, ana amfani da gwajin tauri sosai a cikin bincikar kaddarorin carbide, wanda zai iya kula da daidaitaccen tsarin maganin zafi da kuma binciken sabbin kayan. Gano taurin tungsten carbide galibi yana amfani da na'urar gwajin taurin Vickers don gwada ƙimar taurin HRA. Gwajin yana da siffa mai ƙarfi da daidaita girman girman yanki na gwaji tare da babban inganci.

3. Saurin samarwa

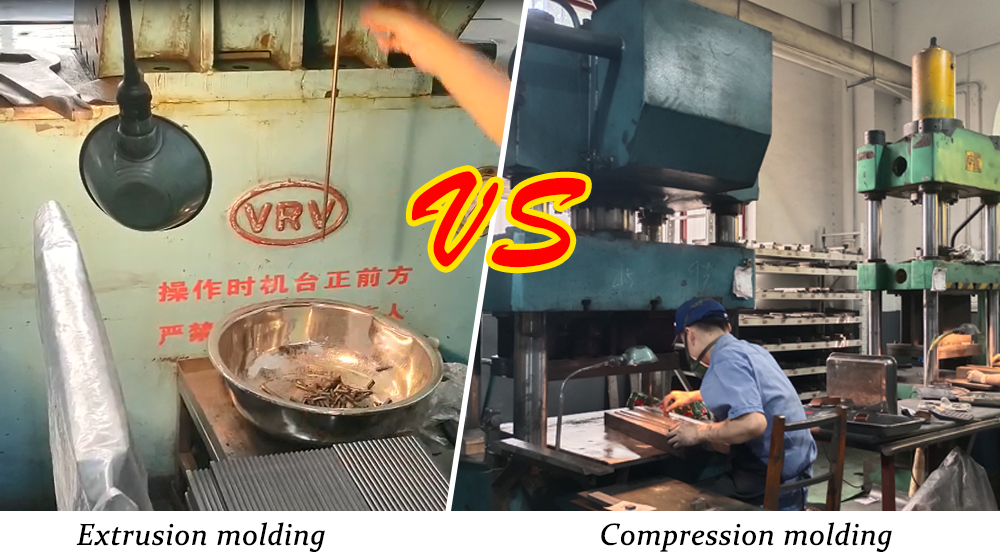

Hanyoyi guda uku daban-daban na haɗakarwa, gami da extrusion, latsa atomatik, da latsawar isostatic mai sanyi, ana amfani da matsakaicin ingancin masana'antar sandar carbide.

Extrusion

Extrusion shine mafi mashahuri hanyar samar da sandunan carbide. Yana da matukar amfani hanya don kera dogon carbide sanduna kamar 330mm, 310mm da 500mm, da dai sauransu. Duk da haka, da lokaci-cinye bushewa tsari shi ne rauni cewa dole ne mu kula.

Latsa atomatik

Dannawa ta atomatik shine hanya mafi inganci don danna gajere masu girma kamar 6 * 50,10 * 75,16 * 100, da dai sauransu. Yana iya ajiye farashi daga yankan sandunan carbide kuma baya buƙatar lokaci don bushewa. Don haka lokacin jagora ya fi sauri fiye da extrusion. Koyaya, ba za a iya kera dogayen sanduna ta wannan hanyar ba.

Busasshen jakar isostatic latsawa

Dry-bag isostatic pressing shine sabuwar fasaha don yin sandunan carbide. Yana iya samar da dogayen sanduna kamar 400mm kuma baya buƙatar kakin zuma azaman wakili mai ƙira. Menene ƙari, baya buƙatar lokaci don bushewa. Wannan shine mafi kyawun zaɓi lokacin yin manyan diamita fiye da 16mm.

4. Ƙwararrun ƙungiyar

Kamfaninmu ya tattara ƙwararrun ma'aikata a fannin ƙira, samarwa, da tallace-tallace. Ma’aikatanmu suna da horo da gogewa. Ƙungiyarmu mai gaskiya ce, tabbatacce, abin dogaro, kuma tana farin cikin samar da mafita ga abokan ciniki da ƙirƙirar ƙima.

Zzbetter ya sami GB/T19001-2016 / ISO9001: 2015 takardar shaidar, tare da ci-gaba kayan aiki, gwajin wuraren, da kuma kwararrun ma'aikata. Muna ɗaukar nauyin ISO9001: buƙatun 2015 don tabbatar da ingancin.

Idan kuna sha'awar tungsten carbide rods kuma kuna son ƙarin bayani da cikakkun bayanai, zaku iya tuntuɓar mu ta waya ko wasiƙa a hagu, ko aika wasiku a ƙasan shafin.