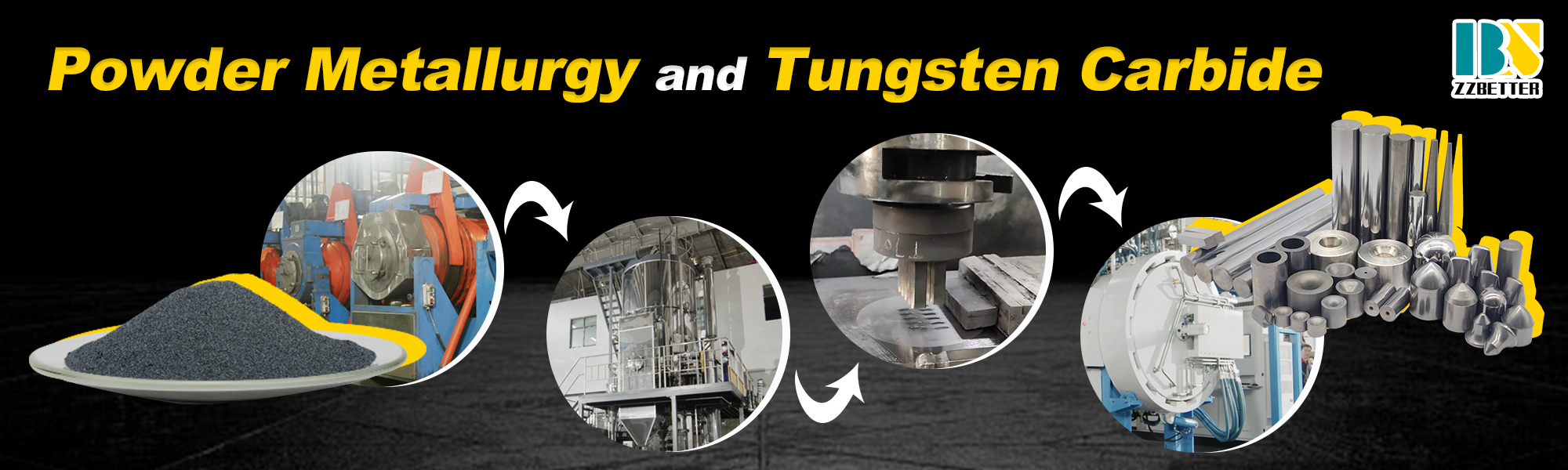

Pauda Metallurgy a me Tungsten Carbide

Pauda Metallurgy a me Tungsten Carbide

I ka ʻoihana hou, hana nui ʻia nā huahana tungsten carbide e ka pauka metallurgy. He nui paha kāu mau nīnau e pili ana i ka pauka metallurgy a me ka tungsten carbide. He aha ka pauda metallurgy? He aha ka tungsten carbide? A pehea ka tungsten carbide i hana ʻia e ka pauka metallurgy? Ma kēia ʻatikala lōʻihi, e loaʻa iā ʻoe ka pane.

ʻO ka mea nui o kēia ʻatikala penei:

1. ʻO ka pauka metallurgy

1.1 Hoʻopuka pōkole o ka pauka metallurgy

1.2 Moʻolelo o ka pauka metallurgy

1.3Material e hana ʻia e ka pauka metallurgy

1.4Kaʻina hana ma ka pauka metallurgy

2.Tungsten carbide

2.1 Hoʻopuka pōkole o ka tungsten carbide

2.2 Nā kumu no ka hoʻohana ʻana i ka metallurgy pauka

2.3 Ke kaʻina hana o ka tungsten carbide

3.Summary

1. ʻO ka pauka metallurgy

1.1 hoʻolauna pōkole o ka pauka metallurgy

ʻO ka pauka metallurgy kahi kaʻina hana e hana ai i nā mea a i ʻole nā mea ʻāpana ma ka hoʻopili ʻana i ka pauka i kekahi ʻano a me ka sintering ma lalo o kahi mahana ma lalo o nā wahi heheʻe. ʻAʻole ʻike ʻia kēia ʻano he ala ʻoi aku ka maikaʻi o ka hana ʻana i nā ʻāpana kiʻekiʻe a hiki i ka hapaha haneli i hala. ʻO ke kaʻina hana o ka tungsten carbide ka nui o nā ʻāpana ʻelua: ʻo kekahi e hoʻopaʻa i ka pauka i loko o kahi make, a ʻo kekahi e hoʻomehana ana i ka compact i kahi wahi pale. Hiki ke hoʻohana ʻia kēia ʻano hana no ka hana ʻana i nā ʻāpana metallurgy pauka structural, bearing self-lubricating, a me nā mea hana ʻoki. I loko o kēia kaʻina hana, hiki i ka pauka metallurgy ke kōkua i ka hoʻohaʻahaʻa i nā poho waiwai a hoʻemi i ke kumukūʻai o nā huahana hope loa. ʻO ka maʻamau, kūpono ka pauka metallurgy no ka hana ʻana i kēlā mau huahana e uku nui ʻia e ke kaʻina hana ʻē aʻe a i ʻole nā mea kūʻokoʻa a hiki ke hana ʻia e ka pauka metallurgy. ʻO kekahi o nā pōmaikaʻi nui loa o ka pauka metallurgy, ʻo ia ka maʻalahi o ke kaʻina hana pauka e hiki ai i ka hoʻopili ʻana i nā ʻano kino o kahi huahana e kūpono i kāu waiwai a me nā koi hana. ʻO kēia mau hiʻohiʻona kino ke ʻano paʻakikī a me ke ʻano, porosity, hana, hana i ke koʻikoʻi, absorption of vibrations, precision nui, hoʻopau ʻili maikaʻi, ʻano nui o nā ʻāpana me nā tolerances haiki, a me nā waiwai kūikawā e like me ka paʻakikī a me ke kūpaʻa ʻana.

1.2 Moʻolelo o ka pauka metallurgy

Hoʻomaka ka mōʻaukala o ka pauka metala me ka pauka metala. Ua loaʻa kekahi mau mea pauda i loko o nā hale kupapaʻu o ʻAigupita i ke kenekulia ʻekolu BC, a ua loaʻa nā metala non-ferrous a me nā ferrous ma waena o ka Hikina, a laila laha i ʻEulopa a me Asia. Ua ʻike ʻia nā kumu ʻepekema o ka pauka metallurgy e ka ʻepekema Lūkini ʻo Mikhail Lomonosov i ke kenekulia 16. ʻO ia ka mea mua i aʻo i ke kaʻina hana o ka hoʻololi ʻana i nā metala like ʻole, e like me ke kēpau, i nā kūlana pauda.

Eia naʻe, i ka makahiki 1827, ua hōʻike kekahi kanaka ʻepekema Lūkini ʻo Peter G. Sobolevsky i kahi ala hou o ka hana ʻana i nā mea nani a me nā mea ʻē aʻe me ka pauka. I ka hoʻomaka ʻana o ke kenekulia iwakālua, ua loli ka honua. Hoʻohana ʻia nā ʻenehana metallurgy pauka, a me ka hoʻomohala ʻana o ka uila, hoʻonui ʻia ka hoihoi. Ma hope o ke kenekulia 21, ua hoʻonui nui ʻia nā huahana i hana ʻia e ka pauka metallurgy.

1.3 Nā mea hana e hana ʻia e ka pauka metallurgy

E like me kā mākou i ʻōlelo ai ma mua, kūpono ka pauka metallurgy no ka hana ʻana i kēlā mau huahana e kūʻai nui ʻia ma ke kaʻina hana ʻē aʻe a i ʻole kūʻokoʻa a hiki ke hana ʻia e ka pauka metallurgy. Ma kēia ʻāpana, e kamaʻilio mākou e pili ana i kēia mau mea kikoʻī.

A. ʻO nā mea kūʻai nui ma ke kaʻina hana ʻokoʻa

ʻO nā ʻāpana kūkulu a me nā mea porous he mau mea i uku nui ʻia e nā ʻano hana ʻē aʻe. ʻO nā ʻāpana i kūkulu ʻia kekahi mau metala, e like me ke keleawe, keleawe, keleawe, aluminika, a pēlā aku. Hiki iā lākou ke hana ʻia e nā ʻano hana ʻē aʻe. Eia naʻe, makemake nā kānaka i ka pauka metallurgy ma muli o ke kumukūʻai haʻahaʻa. ʻO nā mea porous e like me ka mālama ʻana i ka ʻailahana pinepine ʻia nā bearings e ka pauka metallurgy. Ma kēia ala, hiki i ka hoʻohana ʻana i ka metallurgy pauka ke hōʻemi i nā kumukūʻai mua.

B.Unique mea hiki ke hana wale ia e ka pauda metallurgy

ʻElua ʻano mea kū hoʻokahi ʻaʻole hiki ke hana ʻia e nā ʻano hana ʻē aʻe. ʻO lākou nā metala refractory a me nā mea hoʻohui.

He kiʻekiʻe ko nā metala refractory a he paʻakikī ke hana ʻia ma ka hoʻoheheʻe ʻana a me ka hoʻolei ʻana. ʻO ka hapa nui o kēia mau metala he palupalu. ʻO Tungsten, molybdenum, niobium, tantalum, a me ka rhenium no kēia mau metala.

No nā mea i hoʻohui ʻia, aia nā mea like ʻole, e like me nā mea hoʻopili uila, nā metala paʻakikī, nā mea friction, nā mea hana ʻoki daimana, nā huahana wrought, soft magnetic composite, a pēlā aku. ʻAʻole hiki ke hoʻoheheʻe ʻia kēia mau metala ʻelua a ʻoi aku paha, a he kiʻekiʻe ko kekahi mau metala.

1.4Ka hana ʻana ma ka pauka metallurgy

ʻO ke kaʻina hana nui i ka pauka metallurgy ka hui ʻana, ka hoʻopaʻa ʻana, a me ka sintering.

1.4.1 Hui

E hoʻohui i ka pauka metala a i ʻole ka pauka. Hana ʻia kēia kaʻina hana i loko o ka mīkini wili pōleʻa me ka metala binder.

1.4.2 Compact

E hoʻouka i ka hui ʻana i loko o ka die a i ʻole ka poʻi a kau i ke kaomi. Ma kēia kaʻina hana, ua kapa ʻia nā compacts carbide tungsten ʻōmaʻomaʻo, ʻo ia hoʻi ka tungsten carbide unsintered.

1.4.3 Sinter

E wela i ka tungsten carbide ʻōmaʻomaʻo i loko o kahi ea pale ma kahi mahana ma lalo o ka helu heheʻe o nā mea nui i hui pū nā ʻāpana pauda a hāʻawi i ka ikaika kūpono i ka mea no ka hoʻohana ʻana. Kapa ʻia kēia ʻo ka sintering.

2.Tungsten carbide

2.1 Hoʻopuka pōkole o ka tungsten carbide

ʻO Tungsten carbide, i kapa ʻia hoʻi ʻo tungsten alloy, alloy hard, hard metal, a i ʻole cemented carbide, ʻo ia kekahi o nā mea hana paʻakikī loa o ka honua, ma hope o ke daimana. Ma ke ʻano he tungsten a me ke kalapona, loaʻa ka tungsten carbide i nā pono o nā mea maka ʻelua. He nui nā waiwai maikaʻi e like me ka paʻakikī kiʻekiʻe, ka ikaika maikaʻi, ke kūpaʻa ʻaʻahu, ka hopena o ka hopena, ka haʻalulu, ka lōʻihi, a pēlā aku. Hiki i nā māka ke lilo i ʻāpana e hoʻoikaika i ka hana o ka tungsten carbide ponoʻī. Nui nā moʻo grads, e like me YG, YW, YK, a pēlā aku. He ʻokoʻa kēia mau papa hana mai ka pauka binder i hoʻohui ʻia i ka tungsten carbide. Koho ʻo YG series tungsten carbide i ka cobalt i kāna mea hoʻopili, aʻo YK series tungsten carbide e hoʻohana i ka nickel i kāna mea hoʻopili.

Me ka nui o nā pono i hoʻopaʻa ʻia i kēia ʻano mea paahana, he ākea ka tungsten carbide. Hiki ke hana ʻia ka tungsten carbide i nā ʻano huahana like ʻole, me nā pihi tungsten carbide, tungsten carbide rods, tungsten carbide plates, tungsten carbide end mill, tungsten carbide burrs, tungsten carbide blades, tungsten carbide punch pins, tungsten carbide welding rods, so ma. Hiki ke hoʻohana nui ʻia ma ke ʻano he ʻāpana drill bits no ka tunneling, eli, a me ka mining. A hiki iā lākou ke hoʻohana ʻia ma ke ʻano he mea ʻokiʻoki e hana i ka ʻokiʻoki, wili, huli ʻana, grooving, a pēlā aku. Ma waho aʻe o ka noi ʻoihana, hiki ke hoʻohana ʻia ka tungsten carbide i ke ola o kēlā me kēia lā, e like me ka pōpō liʻiliʻi i ka nib o ka peni gel.

2.2 Nā kumu no ka hoʻohana ʻana i ka metallurgy pauka

ʻO ka tungsten carbide he metala refractory, no laila paʻakikī ke hana ʻia e nā ʻano hana maʻamau. ʻO Tungsten carbide kahi mea hiki ke hana wale ʻia e ka pauka metallurgy. Ma waho aʻe o ka tungsten carbide, loaʻa nā huahana tungsten carbide i nā metala ʻē aʻe, e like me ka cobalt, nickel, titanium, a i ʻole tantalum. Hoʻohui ʻia lākou, kaomi ʻia e nā mold, a laila sintered i nā wela kiʻekiʻe. He kiʻekiʻe ka helu hehee ʻana o Tungsten carbide, a pono e hoʻopaʻa ʻia ma kahi kiʻekiʻe o 2000鈩? e hana i ka nui a me ke ʻano a loaʻa ka paʻakikī kiʻekiʻe.

2.3 Ke kaʻina hana o ka tungsten carbide

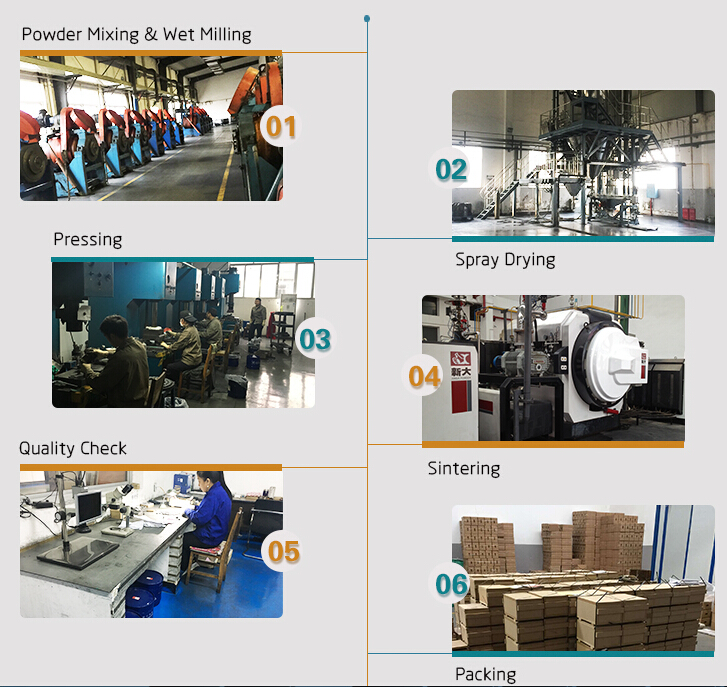

I ka hale hana, hoʻohana mākou i ka pauka metallurgy e hana i nā huahana tungsten carbide.ʻO ka hana nui o ka pauka metallurgy ka hui ʻana i nā pauka, nā pauka paʻa, a me nā ʻōmaʻomaʻo sinter. Ke noʻonoʻo nei i nā waiwai kūikawā o ka tungsten carbide a mākou i kamaʻilio ai ma ka 2.1 Nā hoʻolauna pōkole i ka tungsten carbide, ʻoi aku ka paʻakikī o ka hana ʻana o ka tungsten carbide. ʻO nā kiko'ī penei:

2.3.1 Huihui

I ka wā o ka hui ʻana, e hui pū nā limahana i ka pauka tungsten carbide kiʻekiʻe a me ka pauka binder ka nui o ka cobalt a i ʻole ka pauka nickel, ma kahi ʻāpana. Hoʻoholo ʻia ka ʻāpana e ka māka e koi ai nā mea kūʻai aku. No ka laʻana, aia he 8% cobalt pauka i ka YG8 tungsten carbide. Loaʻa nā pono like ʻole o nā pauka binder like ʻole. E like me ka mea maʻamau, hiki i ka cobalt ke pulu i nā ʻāpana tungsten carbide a hoʻopaʻa paʻa iā lākou. Eia nō naʻe, ke piʻi nei ke kumukūʻai o ka cobalt, a ʻoi aku ka kakaikahi o ka metala cobalt. ʻO nā metala hoʻopaʻa ʻelua ʻelua he nickel a me ka hao. ʻO nā huahana Tungsten carbide me ka pauka hao e like me ka mea hoʻopaʻa ʻia he haʻahaʻa haʻahaʻa ka ikaika mechanical ma mua o ka pauka cobalt. I kekahi manawa, e hoʻohana nā hale hana i ka nickel i mea pani no ka cobalt, akā ʻoi aku ka haʻahaʻa o nā waiwai o nā huahana tungsten carbide-nickel ma mua o nā huahana tungsten carbide-cobalt.

2.3.2 Ka wili pulu

Hoʻokomo ʻia nā hui ʻana i loko o ka mīkini wili pōleʻa, kahi i loaʻa ai nā tungsten carbide liners a i ʻole nā mea kila kila. I ka wā wili pulu, hoʻohui ʻia ka ethanol a me ka wai. ʻO ka nui o ka palaoa o nā ʻāpana tungsten carbide e hopena i nā waiwai o nā huahana hope. ʻO ka ʻōlelo maʻamau, ʻo ka tungsten carbide me ka nui o ka nui o ka palaoa e loaʻa ka paʻakikī haʻahaʻa.

Ma hope o ka milling pulu, e ninini ʻia ka hui ʻana o ka slurry i loko o ka pahu ma hope o ke kānana ʻana, he mea nui ia e pale ai i ka tungsten carbide mai ka haumia. Mālama ʻia ka slurry tungsten carbide i loko o ka pahu e kali ai i nā ʻanuʻu aʻe.

2.3.3 Ehu maloo

ʻO kēia kaʻina hana e hoʻoheheʻe i ka wai a me ka ethanol i ka tungsten carbide a hoʻomaloʻo i ka pauka hui ʻana o ka tungsten carbide i loko o kahi hale kiaʻi maloʻo. Hoʻohui ʻia nā kinoea hanohano i ka hale kiaʻi spray. No ka hōʻoia i ka maikaʻi o ka carbide tungsten hope loa, pono e maloʻo loa ka wai i loko o ka carbide tungsten.

2.3.4 Anana

Ma hope o ka hoʻomaloʻo maloʻo, e kānana nā limahana i ka pauka tungsten carbide e wehe i nā puʻupuʻu oxidation hiki ke hoʻopilikia i ka hoʻopili ʻana a me ka sintering o ka tungsten carbide.

2.3.5 Hoʻopili

I ka wā o ka hoʻopaʻa ʻana, e hoʻohana ka mea hana i nā mīkini e hana i nā tungsten carbide green compacts i nā ʻano nui a me nā ʻano like ʻole e like me nā kiʻi. ʻO ka ʻōlelo maʻamau, kaomi ʻia nā compact green e nā mīkini ʻakomi. ʻOkoʻa kekahi mau huahana. No ka laʻana, hana ʻia nā koʻokoʻo tungsten carbide e nā mīkini extrusion a i ʻole nā mīkini isostatic dry-bag. ʻOi aku ka nui o nā ʻōmaʻomaʻo ʻōmaʻomaʻo ma mua o nā huahana tungsten carbide hope loa, no ka mea, e emi ana nā compacts i ka sintering. I ka wā o ka hoʻopaʻa ʻana, e hoʻohui ʻia kekahi mau mea hana e like me ka paraffin wax e loaʻa ai nā compacts i manaʻo ʻia.

2.3.6 Hoʻopili

Me he mea lā he hana maʻalahi ka sintering no ka mea pono nā limahana e hoʻokomo i nā mea ʻōmaʻomaʻo i loko o ka umu sintering. ʻO ka ʻoiaʻiʻo, paʻakikī ka sintering, a ʻehā mau pae i ka wā o ka sintering. ʻO ia ka wehe ʻana i ka mea hoʻoheheʻe a me ka pae mua o ka puhi ʻana, ka pae sintering pae paʻa, ka pae hoʻoheheʻe wai, a me ka pae hoʻoilo. Hoʻemi nui nā huahana tungsten carbide i ka wā o ka hoʻopaʻa ʻana.

I ka sintering, pono e hoʻonui mālie ka mahana, a hiki i ka wela ke piʻi i kona piko i ke kolu o ka pae, ka pae wai sintering. Pono e maʻemaʻe loa ke kaiapuni sintering. E emi nui nā huahana tungsten carbide i kēia kaʻina hana.

2.3.7 Nānā hope loa

Ma mua o ka hoʻopaʻa ʻana o nā limahana i nā huahana tungsten carbide a hoʻouna iā lākou i nā mea kūʻai aku, pono e nānā pono ʻia kēlā me kēia ʻāpana huahana tungsten carbide. Nā lako like ʻole i loko o nā hale hanae hoʻohana ʻia i kēia kaʻina hana, e like me ka Rockwell hardness tester, metallurgical microscope, density tester, coercimeter, a pēlā aku. ʻO ko lākou ʻano maikaʻi a me nā waiwai, e like me ka paʻakikī, ka paʻa, ka hale o loko, ka nui o ka cobalt, a me nā waiwai ʻē aʻe, pono e nānā ʻia a hōʻoia.

3.Summary

Ma ke ʻano he mea hana kaulana a hoʻohana nui ʻia, he mākeke ākea ka tungsten carbide i ka ʻoihana hana. E like me kā mākou i kamaʻilio ai e pili ana i luna, he wahi hoʻoheheʻe kiʻekiʻe ka tungsten carbide. A he hui ia o tungsten, carbon, a me kekahi mau metala ʻē aʻe, no laila paʻakikī ka tungsten carbide e hana ʻia e nā ʻano kuʻuna ʻē aʻe. He kuleana koʻikoʻi nā kāne pauka metallurgy i ka hana ʻana i nā huahana tungsten carbide. Ma ka pauka metallurgy, loaʻa nā huahana tungsten carbide i nā ʻano waiwai like ʻole ma hope o ke kaʻina hana. ʻO kēia mau waiwai, e like me ka paʻakikī, ka ikaika, ka pale ʻana, ka pale ʻana i ka corrosion, a me nā mea ʻē aʻe, i hana ʻia i ka tungsten carbide i hoʻohana nui ʻia i ka mining, ʻokiʻoki, kūkulu, ikehu, hana ʻana, pūʻali koa, aerospace, a pēlā aku.

Hāʻawi ʻo ZZBETTER iā ia iho i ka hana ʻana i nā huahana tungsten carbide kiʻekiʻe. Ua kūʻai ʻia kā mākou huahana i nā ʻāina a me nā wahi he nui a lanakila nui hoʻi i ka mākeke kūloko. Hana mākou i nā huahana tungsten carbide like ʻole, e like me nā tungsten carbide rods, tungsten carbide pihi, tungsten carbide make, tungsten carbide blades, tungsten carbide rotary burrs, a pēlā aku. Loaʻa nā huahana i hoʻonohonoho ʻia.

Inā makemake ʻoe i nā huahana tungsten carbide a makemake ʻoe i ka ʻike hou aʻe a me nā kikoʻī, hiki iā ʻoe ke CONTACT US ma ke kelepona a i ʻole leka uila ma ka hema, a i ʻole SEND US MAIL ma lalo o ka ʻaoʻao.