Ka mana maikaʻi o nā mea ʻoki PDC

Ka mana maikaʻi o nā mea ʻoki PDC

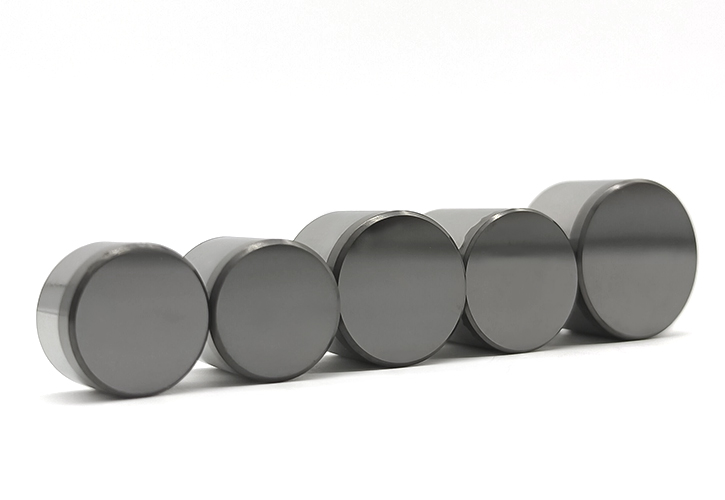

Aia nā mea ʻoki PDC me kahi ʻāpana Polycrystalline Diamond a me ka substrate carbide. Ua kapa ʻia nā mea ʻoki PDC he Polycrystalline Diamond Compact cutters, he ʻano mea paʻakikī loa. Hoʻolaha nui ʻia ka hoʻohana ʻana i nā mea ʻokiʻoki polycrystalline diamond compact (PDC) i kēia mau lā ma muli o kā lākou hana kiʻekiʻe a paʻa i nā wahi paʻakikī.

ʻO nā mea koʻikoʻi no nā mea ʻoki PDC i ka noi ʻana i ka ʻaila ʻaila he maikaʻi a paʻa. Manaʻo wau e ʻae nā mea a pau. Akā, pehea e hoʻomalu ai i ka maikaʻi?

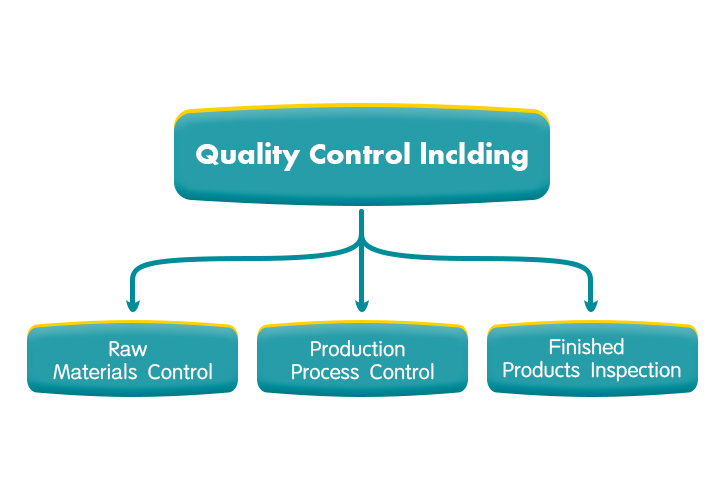

E hōʻoia i kēlā me kēia ʻāpana o ka ʻoki PDC e hele mai ZZKA OInā lima o ka mea kūʻai aku me ke kūlana kiʻekiʻe, ZZKA OIua hoʻokumu i kahi ʻōnaehana mana koʻikoʻi, me ka hoʻokele waiwai maka, ka hoʻokele kaʻina hana, a me ka hoʻopau ʻana i nā huahana. Hoʻomaʻamaʻa nui ʻia kā mākou mea hana a ʻoihana a hoʻolaʻa. Kūkulu ʻia kēlā me kēia ʻokiʻoki PDC me nā mea hana i hoʻomaʻamaʻa nui ʻia a mālama ʻia ke kaomi i nā kaomi i ka wā o ka sintering.

PDC cutter mana maikaʻi:

1. Mea maka

2. Kaʻina hana hana

3. Nānā i nā huahana i hoʻopau ʻia

1. Ka hooponopono waiwai maka

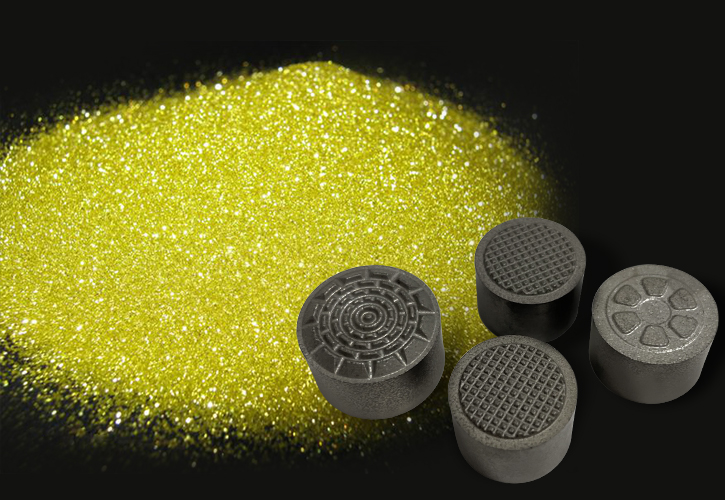

1.1 No ka hana ʻana i ka PDC cutter oilfield drilling application, hoʻohana mākou i ka daimana i lawe ʻia mai. Pono mākou e ʻoki a hana hou iā ia, e hoʻonui i ka nui o ka ʻāpana. Pono mākou e hoʻomaʻemaʻe i ka mea daimana.

1.2 Hoʻohana mākou i ka Laser Particle Size Analyzer no ke kālailai ʻana i ka puʻunaue ʻana o ka nui o ka ʻāpana, ka maʻemaʻe a me ka nui no kēlā me kēia pūʻulu o ka pauka daimana.

1.3 No ka tungsten carbide substrate mākou e hoʻohana i ka papa kūpono me ka hopena kiʻekiʻe.

2. Kaʻina hana

2.1 Loaʻa iā mākou ka mea hoʻohana ʻoihana a me nā ʻoihana kiʻekiʻe e hana i nā mea ʻoki PDC

2.2 I ka wā o ka hana e nānā mākou i ka mahana a me ke kaomi i ka manawa maoli a hoʻoponopono i ka manawa. ʻO 1300 - 1500 ka mahana℃. ʻO 6 - 7 GPA ke kaomi. ʻO ia ka HTHP kaomi.

No ka hana ʻana i hoʻokahi ʻāpana o nā PDC Cutters e pono ma kahi o 30 mau minuke i ka huina.

No kēlā me kēia pūʻulu o nā mea ʻoki PDC, he mea nui ka ʻāpana mua. Ma mua o ka hana nui, e nānā mākou i ka ʻāpana mua e ʻike inā kūpono ia i nā koi o ka mea kūʻai aku no ka nui a me ka hana.

3. Nānā i nā huahana i hoʻopauʻia

No ka hōʻoia ʻana i nā mea ʻoki PDC āpau i kūpono a kūlike, ʻaʻole pono mākou e kāohi wale i ka nānā ʻana i nā mea maka a me ka mana kahe o ka hana a me ka hoʻomaikaʻi ʻana i ka ʻenehana, pono mākou e hana i ke kūkulu ʻana i kahi keʻena hoʻokolohua me nā keʻena hoʻāʻo kiʻekiʻe e hoʻohālike i nā kūlana wili ʻaila a hoʻāʻo i nā mea ʻoki PDC ma ka hale hana. ma mua o ka hāʻawi ʻana i kā mākou mea kūʻai.

No ka hoʻopau ʻana i ka huahana e hana mākou mai nā ʻaoʻao lalo:

Ka nui a me ka nānā 'ana

Hoʻomalu nā hemahema o loko

Hoao hana

3.1 Ka nui a me ka nānā 'ana:anawaena, kiekie, daimana mānoanoa, chamfer, geometric nui, māwae, ʻeleʻele wahi, etc.

3.2 Ka hoomalu ana i na hemahema o loko

No ka hoʻomalu hemahema i loko, e hoʻohana mākou i nā lako nānā ultrasonic C-san i lawe ʻia mai. No nā ʻoki ʻoki PDC i hoʻoili ʻia i ka aila pono mākou e nānā i kēlā me kēia ʻāpana.

Me ka ʻōnaehana C-scanning, hiki i ka hawewe kani ultrasonic ke komo i ka papa PDC a ʻike i kona delamination a i ʻole ka hemahema o ka lua. Hiki i ka ʻōnaehana C-scan ke ʻike i ka nui a me ke kūlana o nā hemahema a hōʻike iā lākou ma ka pale PC. Ma kahi o 20 mau minuke e hana i hoʻokahi manawa nānā.

3.3 Ka ho'āʻo laʻana hana a PDC Cutter:

ʻaʻahu kūʻē

kū'ē hopena

paʻa wela.

3.3.1 Ho'āʻo kūʻē ʻaʻahu:ma ke ana ʻana i ka nui o nā paona i nalowale ma hope o ka hoʻopaʻa ʻana o nā mea ʻoki PDC i ka granite i kekahi manawa, loaʻa iā mākou kahi lākiō lole. ʻO ia ka pohō nui ma waena o nā mea ʻoki PDC a me ka granite. ʻOi aku ka kiʻekiʻe o ka ratio, ʻoi aku ka nui o ka pale ʻana o ka PDC Cutters.

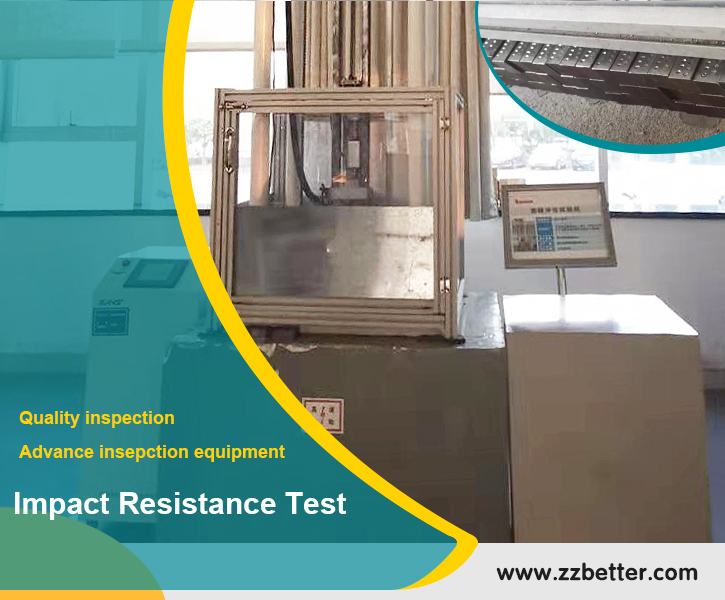

3.3.2Ka hopenaHōʻike kūʻē:Kāhea pū mākou iā ia ʻo Drop-Weight test, me ka hoʻohana ʻana i ka lathe kū i kekahi kiʻekiʻe e hāmama ana ma luna o ka PDC Cutter cutting profile, maʻamau me kahi degere (15-25 degere) paheʻe. ʻO nā paona o kēia lathe kū pololei a me kona kiʻekiʻe i hoʻonohonoho mua ʻia e hōʻike i ke ʻano o ka pale ʻana o kēia ʻoki PDC.

3.3.3 ʻO ka hoʻāʻo kūpaʻa wela:Manaʻo ia e hoʻāʻo inā paʻa ka wela o ka PDC Cutters ma lalo o nā kūlana hana wela kiʻekiʻe. Ma ka hale hana, hoʻokomo mākou i nā mea ʻoki PDC ma lalo o 700-750℃i loko o 10-15 mau minuke a nānā i ke ʻano o ka papa daimana ma hope o ka hoʻoilo maoli ʻana i ka lewa. ʻO ka maʻamau, e hele pū kēia kaʻina hana me kahi pale lole ʻē aʻe a me ke kūpaʻa hopena e hoʻohālikelike i ka maikaʻi o ka mea ʻoki PDC ma mua o ka hoʻāʻo a ma hope o ka hoʻāʻo.

Welina mai e hahai i kā mākou ʻaoʻao hui:https://lnkd.in/gQ5Du_pr

Aʻo hou mai:WWW.ZZBETTER.COM