ʻO nā huaʻōlelo o ka huila paʻa (1)

ʻO nā huaʻōlelo o ka huila paʻa (1)

No ka paipai ʻana i ka hoʻomaopopo ʻana i nā hōʻike a me nā palapala ʻenehana e pili ana i ka paʻa paʻa, hoʻohālikelike i nā huaʻōlelo, a wehewehe i ke ʻano o nā huaʻōlelo loea i nā ʻatikala, eia mākou e aʻo i nā huaʻōlelo o ka alloy paʻa.

Tungsten Carbide

ʻO ka tungsten carbide e pili ana i nā composites sintered i loaʻa i nā carbide metala refractory a me nā mea hoʻopaʻa metala. Ma waena o nā carbide metala e hoʻohana ʻia nei, ʻo tungsten carbide (WC), titanium carbide (TiC), a me tantalum carbide (TaC) nā mea maʻamau. Hoʻohana nui ʻia ka metala Cobalt i ka hana carbide cemented ma ke ʻano he mea hoʻopaʻa. No kekahi mau noi kūikawā, hiki ke hoʻohana ʻia nā mea hoʻopaʻa metala e like me nickel (Ni) a me ka hao (Fe).

ʻO ka mānoanoa

ʻO ka Density e pili ana i ka ratio mass-to-volume o ka mea, ka mea i kapa ʻia ʻo ka gravity kikoʻī. Loaʻa i kona nui ka nui o nā pores i loko o ka mea. ʻO ka tungsten carbide (WC) he 15.7 g/cm³ a me ka cobalt (Co) he 8.9 g/cm³. No laila, i ka emi ʻana o ka cobalt (Co) i loko o nā tungsten-cobalt alloys (WC-Co), e piʻi aʻe ka nui o ka nui. ʻOiai ʻoi aku ka liʻiliʻi o ka titanium carbide (TiC) ma mua o ka tungsten carbide, he 4.9 g/cm3 wale nō. Me kekahi mau mea hoʻohui kemika o ka mea, ka piʻi ʻana o nā pores i loko o ka mea i hopena i ka emi ʻana o ka density.

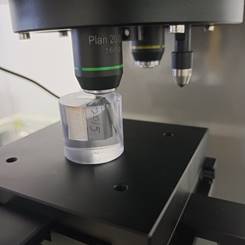

ʻoʻoleʻa

ʻO ka paʻakikī e pili ana i ka hiki i kahi mea ke pale aku i ka hoʻololi ʻana o ka plastic.

Hoʻohana nui ʻia ʻo Vickers hardness (HV) ma ka honua. ʻO kēia ʻano ana paʻakikī e pili ana i ka waiwai paʻakikī i loaʻa ma ka hoʻohana ʻana i ke daimana e komo i ka ʻili o ka hāpana e ana i ka nui o ka indentation ma lalo o kekahi kūlana haʻawe. ʻO ka Rockwell hardness (HRA) kekahi ʻano ana i hoʻohana mau ʻia. Hoʻohana ia i ka hohonu komo o kahi cone daimana maʻamau e ana i ka paʻakikī. Hiki ke hoʻohana ʻia ka paʻakikī Vickers a me ka paʻakikī ʻo Rockwell no ke ana paʻakikī o ka carbide cemented, a hiki ke hoʻololi ʻia nā mea ʻelua i kekahi i kekahi.

Ka ikaika kulou

ʻIke ʻia ka ikaika kulou ʻo ia ka ikaika haʻihaʻi transverse a i ʻole ka ikaika flexural. Hoʻohui ʻia nā ʻāpana paʻa ma ke ʻano he kaola kākoʻo maʻalahi ma nā pivots ʻelua, a laila hoʻopili ʻia kahi ukana i ke kikowaena o nā pivots ʻelua a hiki i ka haki ʻana o ka alloy paʻa. Hoʻohana ʻia nā waiwai i helu ʻia mai ke ʻano wili no ka ukana e pono ai e haki, a me ka ʻāpana kea o ka hāpana. I loko o nā tungsten-cobalt alloys (WC-Co), piʻi ka ikaika flexural me ka cobalt (Co) content i loko o ka tungsten-cobalt alloys, akā hiki i ka ikaika flexural ke kiʻekiʻe loa i ka wā e hiki ai ka ʻike cobalt (Co) ma kahi o 15%. Ana 'ia ka ikaika flexural ma ka 'awelika ana i kekahi mau ana. E ʻokoʻa nō hoʻi kēia waiwai me ka geometry o ka hāpana, ke ʻano o ka ʻili (smoothness), ke koʻikoʻi o loko, a me nā hemahema o loko o ka mea. No laila, ʻo ka ikaika flexural kahi ana o ka ikaika wale nō, a ʻaʻole hiki ke hoʻohana ʻia nā waiwai ikaika flexural i kumu no ke koho ʻana i nā mea.

Porosity

Hoʻokumu ʻia ka carbide cemented e ka pauka metallurgy kaʻina ma ke kaomi ʻana a me ka sintering. Ma muli o ke ʻano o ke ʻano, hiki ke mau ka nui o ka porosity i loko o ke ʻano metallurgical o ka huahana.

Hiki i ka emi ʻana o ka porosity ke hoʻomaikaʻi maikaʻi i ka hana holoʻokoʻa o ka huahana. ʻO ke kaʻina hana hoʻoheheʻe kaomi he ala kūpono e hōʻemi i ka porosity.