He aha ka ʻokoʻa ma waena o ka hardfacing a me ka pale ʻana

ʻO "ke alo paʻakikī" a me ka "cladding" ʻelua mau huaʻōlelo i hoʻohana pinepine ʻia, ʻoiaʻiʻo, he mau noi like ʻole. Aia nā carbide a, i ka nui o nā hihia, he carbide sima kēia.

ʻO ka hoʻopaʻa ʻana ʻo ia ka hoʻohana ʻana i kahi metala like ʻole i ka ʻili o kekahi metala ʻē aʻe. E hoʻohana maʻamau ka pale ʻana i nā mea i uhi ʻia e like me ka mea kumu akā i nā manawa he nui e hoʻohana i nā mea ʻokoʻa e hāʻawi i kahi waiwai pono i kēlā ʻāpana wale nō o ka ʻāpana, e like me ka paʻakikī kiʻekiʻe, ka pale ʻana i ka corrosion, a i ʻole e hālāwai me kahi hana hoʻoponopono. E like me ka hoʻopaʻa ʻana, ʻaʻole hiki ke hana ʻia ka paʻakikī laser a pono e lepo.

Paakiki VS. Kaʻina hoʻopaʻa ʻana

Eia nō naʻe, ʻo ka paʻakikī a me ka hoʻopaʻa ʻana he mau kaʻina hana overlay i ʻokoʻa i nā hiʻohiʻona waiwai e kū ana i nā koi like ʻole, hiki ke hoʻokō ʻia lāua me ka hoʻohana ʻana i nā kaʻina like:

• Nā Lasers

• ʻEhu wela

• ʻO ka wiliwili arc-cored arc a i ʻole FCAW

• Plasma Transfer Arc [PTA] wiliwili

ʻO ka koho ma waena o ka hardfacing a me ka cladding e iho i lalo i nā ʻano āu e makemake ai e hāʻawi, nā mea i pili, a me ka ʻike o ke kaiapuni i kau ʻia ka ʻili. I ka paʻakikī, hiki ke hoʻohana ʻia ka waihona carbide/metala koʻikoʻi a paʻa ʻole e ka laser, ka hoʻoheheʻe ʻana i ka wela, ka spray-fuse, a i ʻole ka wili. ʻOi aku ka maikaʻi o ka pulupulu wela no nā mea pili i ka ʻino ʻana o ka wela, e kūʻē i ka spray-fuse e pono ai ke puhi ʻana i ka lapalapa a me ka hui ʻana me ka lama. ʻAʻole ʻo ka ʻūhā wela he hana hoʻoheheʻe; no laila, haʻahaʻa loa ka ikaika o ka paʻa i ka hoʻohālikelike ʻia me ka overlay welded a brazed. Hiki ke hoʻohana ʻia ka weld hardfacing kuʻuna e hoʻopili i kahi papa mānoanoa loa (a hiki i 10's o mm) o nā mea ʻaʻahu. Loaʻa nā pōmaikaʻi o ka laser hardfacing ma mua o nā kaʻina hana ʻē aʻe no ka mea he kaʻina hana hoʻoheheʻe i loaʻa ka wela haʻahaʻa, haʻahaʻa haʻahaʻa, a me ka emi ʻana o ka carbide. ʻO kēia ka mea e hiki ai ke hoʻokō i nā overlay hardfacing lahilahi.

ʻO ka hoʻopaʻa ʻana he hana weld overlay e hāʻawi ana i kahi ʻili hou loa i hiki ke hoʻohana ʻia me nā ʻano mea overlay nui i nā ʻano like ʻole e like me ka pauka, uea, a i ʻole uea cored. He aha hou aʻe, hiki ke hoʻohana ʻia nā kaʻina hana overlay kuʻuna e like me ka papa inoa ma luna. E like me ka laser hardfacing, ʻoi aku ka maikaʻi o ka pale ʻana i ka laser ma mua o nā kaʻina hana ʻē aʻe no ka mea he kaʻina hana kuʻi ʻana i ka wela haʻahaʻa a me ka dilution haʻahaʻa. ʻO kēia ka mea e hiki ai ke hoʻokō i nā uhi uhi lole lahilahi.

Hoʻohana ʻia ka laser hardfacing a me ka cladding i nā mākeke ʻoihana āpau me nā noi e like me:

• ʻAila a me ke kinoea

• Kaʻa

• Mea hana kūkulu

• Mahiai

• Hoʻolima

• Koa

• Hoʻoulu ikehu

• Hoʻoponopono a hoʻomaikaʻi hou ʻana i nā mea hana, nā ʻili turbine, a me nā ʻenekini

ʻO ka laser hardfacing a me ka laser cladding e hāʻawi i nā pono o ka distortion thermal liʻiliʻi, ka huahana kiʻekiʻe, a me ka uku-pono.

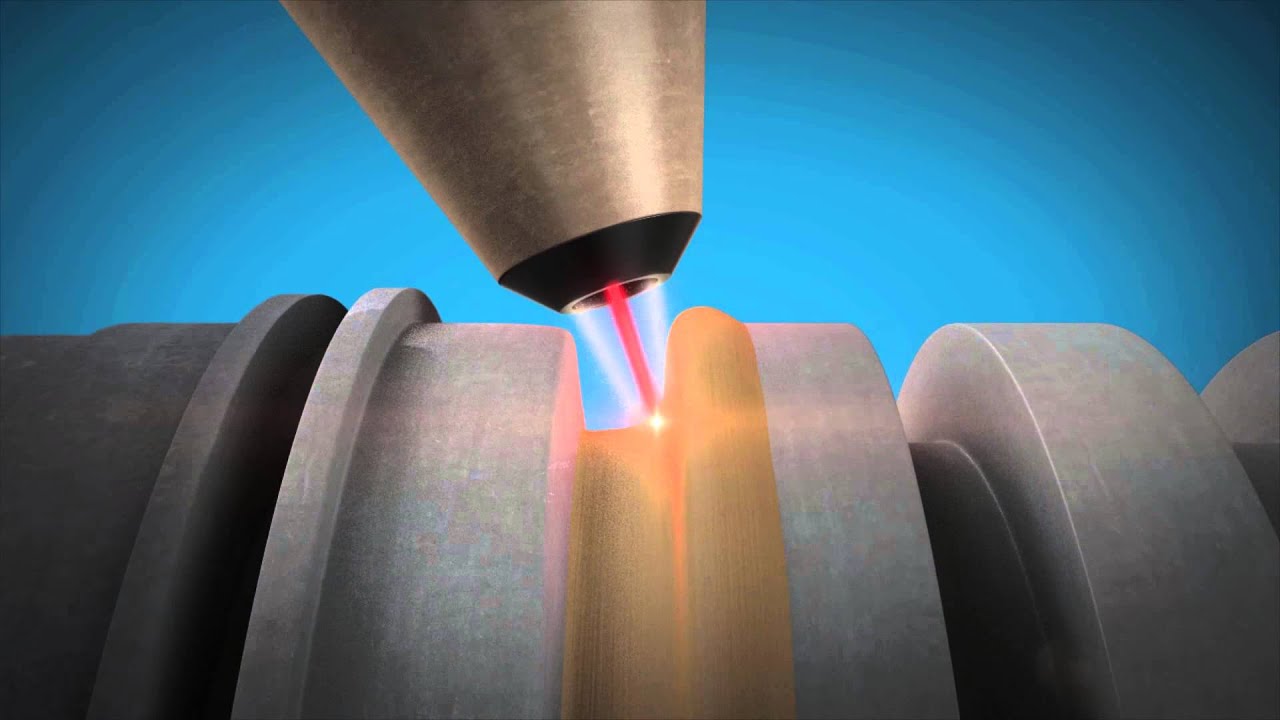

Nā Lasers I loko o nā kaʻina hana paʻakikī a hoʻopaʻa ʻia

ʻO ka hoʻohana ʻana i nā lasers he kumu wela i ka hardfacing a me ka cladding e hāʻawi i ka pololei a me ka haʻahaʻa haʻahaʻa o ka dilution kemika e weld i ʻelua mau mea. Hāʻawi ia i kahi ala maikaʻi loa e hoʻohana ai i nā mea substrate liʻiliʻi ma o ka hoʻopili ʻana i kahi weld overlay, kahi e hāʻawi ai i ka corrosion, oxidation, aahu, a me ka pale wela. ʻO ke kiʻekiʻe o ka hana kiʻekiʻe e hiki ai ke hoʻopau ʻia nā huahana me nā pono kumu kūʻai waiwai e hana i ka pale laser a me ka hardfacing i koho kaulana no nā ʻoihana he nui.