Cov txheej txheem tsim khoom thiab tsim cov txheej txheem ntawm Cemented Carbide Qws

Cov txheej txheem tsim khoom thiab tsim cov txheej txheem ntawm Cemented Carbide Qws

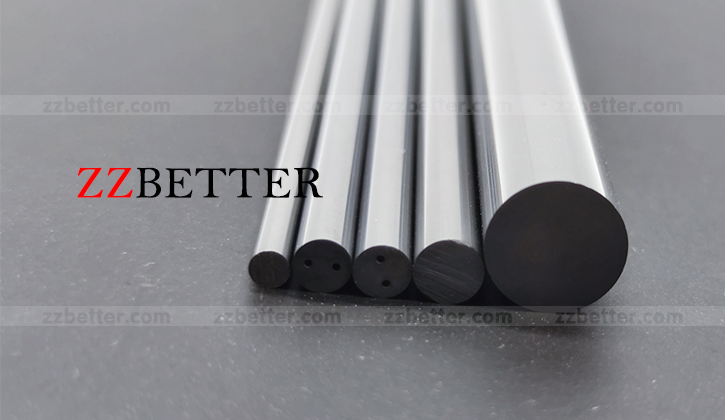

Cemented carbide bar yog cemented carbide round rods. Cemented carbide yog cov khoom sib xyaw ua ke ntawm cov khoom siv hlau refractory (theem nyuaj) thiab cov hlau sib txuas (lub sijhawm sib khi) ua los ntawm cov hmoov metallurgy.

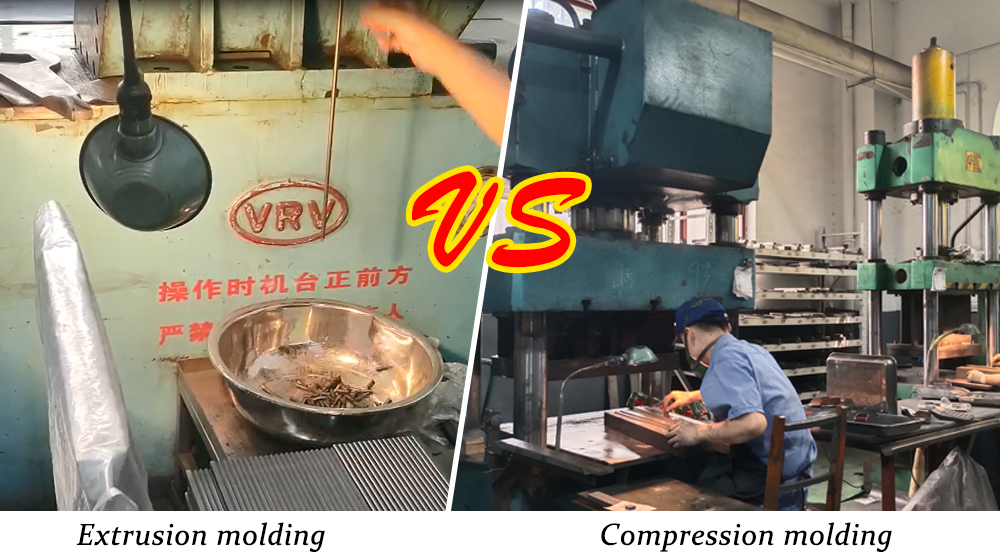

Muaj ob txoj hauv kev rau cemented carbide round rods. Ib txoj hauv kev yog extrusion forming, uas yog ib txoj hauv kev tsim cov pas nrig ntev. Hom cemented carbide rods no tuaj yeem txiav mus rau txhua qhov ntev uas tus neeg siv xav tau thaum lub sijhawm extrusion txheej txheem. Txawm li cas los xij, qhov ntev tag nrho tsis tuaj yeem tshaj 350mm. Lwm qhov yog compression molding, uas yog ib txoj kev tsim nyog rau luv bar ntau lawm. Raws li lub npe implies, cov cemented carbide hmoov yog nias rau hauv pwm.

Cov khoom siv hlau yog ua los ntawm cov hlau refractory thiab cov hlau sib txuas los ntawm cov txheej txheem hmoov metallurgy. Cemented carbide muaj cov khoom zoo heev xws li siab hardness, hnav tsis kam, zoo zog thiab toughness, kub tsis kam, thiab corrosion kuj. tshwj xeeb tshaj yog nws cov hardness siab thiab hnav tsis kam, uas tseem tsis hloov txawm nyob rau ntawm qhov kub ntawm 500 ° C, thiab tseem muaj ib tug siab hardness ntawm 1000 ° C. Carbide yog dav siv los ua cov cuab yeej cuab tam, xws li cov cuab yeej tig, milling cutters, planers, xyaum, tho txawv cov cuab yeej, thiab lwm yam rau txiav hlau cam khwb cia hlau, non-ferrous hlau, yas, tshuaj fibers, graphite, iav, pob zeb, thiab zoo tib yam hlau, thiab tseem tuaj yeem siv rau kev txiav ntub kev sib tsoo ntawm cov khoom siv nyuaj xws li cov hlau tsis muaj cua sov, cov hlau tsis muaj hlau, cov hlau manganese siab, cov cuab yeej hlau (pob zeb, ziab txee, Z-hom tov khoom, granulator) --- nias (nrog rau sab-siab hydraulic xovxwm lossis extruder) --- Sintering (degreasing rauv, integrated rauv lossis HIP low-pressure cub)

Cov ntaub ntawv raw yog ntub-milled, qhuav, tov nrog kua nplaum tom qab proportioning, ces qhuav thiab kev nyuaj siab-relieved tom qab molded los yog extruded, thiab qhov kawg alloy dawb paug yog tsim los ntawm degreasing thiab sintering.

Qhov tsis zoo ntawm round bar extrusion ntau lawm yog tias lub voj voog ntau lawm ntev. Extrusion ntawm me me-inch puag ncig tuav hauv qab 3 hli, txiav tawm ob qho kawg yuav nkim qee yam khoom siv. Qhov ntev ntawm qhov me me-inch puag ncig bar ntawm cemented carbide, qhov phem qhov ncaj ntawm qhov khoob. Tau kawg, cov teeb meem ntawm kev ncaj thiab roundness tuaj yeem txhim kho los ntawm kev sib tsoo cylindrical nyob rau theem tom ntej.

Lwm qhov yog compression molding, uas yog siv los tsim cov khoom luv luv. Raws li lub npe implies, muaj pwm uas nias cov cemented carbide hmoov. Qhov kom zoo dua ntawm no cemented carbide bar txoj kev tsim: nws tuaj yeem tsim ib zaug thiab txo cov khib nyiab. Simplify cov txheej txheem hlau txiav thiab txuag cov khoom siv qhuav ntawm txoj kev extrusion. Lub sijhawm luv luv saum toj no tuaj yeem txuag tau 7-10 hnub rau cov neeg siv khoom.

Hais lus nruj me ntsis, isostatic nias kuj yog rau molding. Isostatic nias yog txoj kev tsim zoo tshaj plaws rau kev tsim cov khoom loj thiab ntev carbide puag ncig tuav. Los ntawm kev sib khi ntawm cov pistons sab saud thiab qis, lub twj tso kua mis siab txhaj cov kua nruab nrab ntawm lub tog raj kheej siab thiab cov roj hmab uas muaj zog, thiab lub siab yog kis los ntawm cov roj hmab pressurized los ua cov cemented carbide hmoov pressurized.

Yog tias koj txaus siab rau cov khoom lag luam tungsten carbide thiab xav paub ntau ntxiv thiab cov ntsiab lus, koj tuaj yeem tiv tauj peb hauv xov tooj lossis xa ntawv ntawm sab laug, lossis xa mus rau US MAIL hauv qab ntawm nplooj ntawv.