Spherical Cast tungsten Carbide hmoov

Spherical Cast tungsten Carbide hmoov

1. Dab tsi yog Spherical Cast Tungsten Carbide Powder?

Spherical cam khwb cia tungsten carbide hmoov muaj cov xim grey tsaus nti, uas yog tsim los ntawm ultra-high-temperature spheroidization lossis gas atomization txheej txheem.

Dendritic siv lead ua qauv tsim los ntawm WC thiab W2C: siab melting point (2525 ℃), siab hardness (HV0.1≥2700), siab feather qauv (cov ntsiab lus≥90%), tshuaj ruaj khov, zoo heev flowability, siab microhardness, thiab siab hnav tsis kam. .

Cov khoom no yog siv rau pob zeb diamond roj laum me ntsis matrix cov ntaub ntawv, plasma (PTA) surfacing cov ntaub ntawv, tshuaj tsuag vuam cov ntaub ntawv, thiab cemented carbide hnav-resistant electrodes (hlau).

2. Yuav ua li cas tsim nws?

Lub spherical tungsten carbide hmoov feem ntau yog tsim los ntawm cov cam khwb cia tungsten carbide lub zog los yog sib xyaw ntawm tungsten (W), tungsten carbide (WC), thiab carbon (C). Feem ntau muaj ob txoj kev tsim khoom: (1) qhov sib xyaw ntawm tungsten hmoov sib xyaw nrog tungsten carbide thiab carbon hmoov yog yaj ua ntej. Cov molten sib tov yog atomized los ntawm kev sib hloov atomizing los yog ultra-high-temperature melting & atomizing txheej txheem. Nws spheroids rau hauv spherical WC hais thaum lub sij hawm ceev ceev solidification txheej txheem vim nto nro. (2) Lwm cov txheej txheem yog raws li kev hloov kho ntawm cov cam khwb cia tungsten carbide hmoov. Plasma spraying, hluav taws xob induction, los yog hluav taws xob tiv thaiv rauv melting yog siv thaum lub sij hawm spheroidization txheej txheem kom tau zoo spherical WC hais.

3. Yuav ua li cas txog nws lub cev kev ua tau zoo ntawm nws?

Tswj tau tag nrho cov ntsiab lus carbon;

Uniform W2C thiab WC ob-theem qauv;

High microhardness (HV0.1≥2700);

Siab purity (≥99.9%);

Tsawg oxygen (≤100ppm);

Siab sphericity (≥98%);

Smooth nto;

Tsis muaj satellite pob;

Uniform particle loj faib;

Cov khoom ntws zoo heev (≤6.0s / 50g);

High bulk ntom (≥9.5g / cm3);

Kais ceev (≥10.5g / cm3).

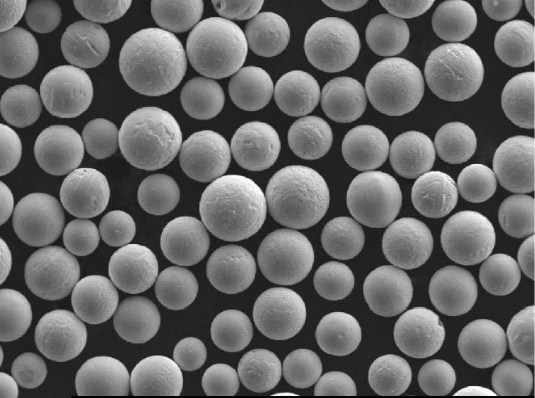

Cov cam khwb cia kheej kheej tungsten carbide hmoov muaj cov microstructure ntawm zoo equiaxed dendrites, raws li qhia hauv daim duab saum toj no. Daim duab SEM hauv qab no qhia meej meej nws cov morphology ntawm ntom homogeneous kheej kheej WC hais. Nws tuav cov khoom siv tshuaj ruaj khov, zoo yooj thiab hardness, thiab zoo heev hnav / abrasion kuj. Qhov luaj li cas ntawm cam khwb cia kheej kheej WC hmoov yog los ntawm 0.025 hli mus rau 0.25 hli, uas ua rau pom ib qho tsaus grey luster. Nws qhov ceev tshwj xeeb yog 15.8 ~ 16.7 g / cm3 nrog micro-hardness li ntawm 2700 ~ 3300 kg / mm2.

4. Nws cov ntawv thov yog dab tsi?

Cov cam khwb cia kheej kheej tungsten carbide hmoov yog dav siv rau hardfacing ntawm drilling cov khoom thiab PDC laum cov cuab yeej, HVOF los yog PTA thermal spray rau ntawm qhov chaw ntawm lub rooj zaum valve los yog sab hauv, thiab weld overlay ntawm lub flange tig, thiab lwm yam.

Yog tias koj txaus siab rau cov khoom lag luam tungsten carbide thiab xav paub ntau ntxiv thiab cov ntsiab lus, koj tuaj yeem tiv tauj peb hauv xov tooj lossis xa ntawv ntawm sab laug, lossis xa mus rau US MAIL hauv qab ntawm nplooj ntawv.