Kev Tsim Kho Technology ntawm Hard Alloy

Kev Tsim Kho Technology ntawm Hard Alloy

Hard alloyyog ib hom khoom siv tawv uas yog tsim los ntawm refractory hlau nyuaj compound thiab bonded hlau; nyuaj alloys, yog cov ntaub ntawv nyuaj uas muaj siab hnav tsis kam thiab toughness, uas yog tsim los ntawm hmoov metallurgy; vim nws cov kev ua tau zoo heev, cemented carbide yog dav siv hauv machining, hnav-resistant qhov chaw, mining, geological drilling, roj mining, machinery qhov chaw thiab lwm yam.

Hard Metals Production Technology deals nrog cov cuab yeej tsim khoom thiab tshawb xyuas cov qauv thiab lub cev-tsim khoom ntawm cov hlau tawv. Ib qho ntawm cov ntsiab lus tseem ceeb hauv kev kawm txuj ci yog lub teb chaws tsim cov hlau tawv. Kev txhim kho thiab kev taw qhia ntawm cov hlau hnyav hnyav ua kom cov khoom tsim tau ua haujlwm yuav nce hauv kev lag luam hlau, mining, roj, thiab thee industries.

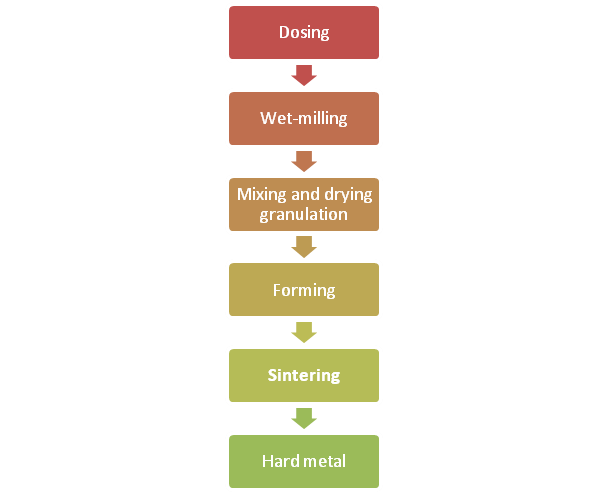

Cov txheej txheem ntau lawm ntawm cemented carbide yog raws li nram no: sib tov npaj, nias thiab sib sau, sintering. Tag nrho muaj 3 txheej txheem.

Flow daim ntawv ntawm hard alloy ntau lawm txheej txheem

Cov khoom siv raw thiab ib qho me me ntawm cov khoom ntxiv uas xav tau yog hnyav thiab thauj mus rau hauv lub pob zeb dov lossis lub pob zeb nplawm. Nyob rau hauv lub pob zeb, cov ntaub ntawv raw yog refined thiab sib npaug. Tom qab cov tshuaj tsuag kom qhuav thiab vibration sifting, qhov sib tov nrog tej yam muaj pes tsawg leeg thiab particle loj yuav tsum tau ua kom tau raws li qhov xav tau ntawm nias txoj kev thiab sintering. Tom qab nias thiab sintering, lub hard alloy blanks raug tso tawm thiab ntim tom qab kev soj ntsuam zoo.

Hard hlau blanks

Txheej txheem ntawm ntxhib cemented carbide:

1. Internal thiab sab nraud xov ua: carbide xov ua yuav tsum tau ua tiav los ntawm xov milling, tsis tuaj yeem ua tiav ncaj qha nrog cov ntsia hlau kais dej.

2. Kev ua tiav ntawm qhov zawj sab hauv: pob zeb diamond sib tsoo pas nrig yuav tsum tau xaiv, thiab cov nyiaj txiav txhua zaus yog tswj tau li ntawm 20 mus rau 30 um. Kev hloov kho tshwj xeeb yuav tsum tau ua raws li qhov zoo thiab qhov tsis zoo ntawm pob zeb diamond sib tsoo pas nrig.

3. EDM

4. Vuam ua: brazing, nyiaj vuam ua

5. Kev sib tsoo ua haujlwm: kev sib tsoo nruab nrab, kev sib tsoo sab hauv, kev sib tsoo nto, cov cuab yeej sib tsoo, lub log sib tsoo feem ntau yog pob zeb diamond sib tsoo log, qhov kev xaiv tshwj xeeb nyob ntawm cov txheej txheem yuav tsum tau ua.

6. Laser ua: laser txiav txoj kev, xuas nrig ntaus yog muaj, tab sis lub thickness ntawm cov txiav yog constrained los ntawm lub hwj chim ntawm lub tshuab laser txwv.

Yog tias koj cov khoom tungsten carbide ua npub lossis "pos huab", koj tsis tas yuav yuav cov khoom siv nyiaj kim kim kom ci thiab txhuam koj cov hniav nyiaj hniav kub tungsten. Ib qho yooj yim sib tov ntawm xab npum dej thiab ib daim ntaub huv si tsuas yog cov khoom koj xav tau los ntxuav cov tawv tawv, khawb resistant hlau. Tsis tas li ntawd, silicon carbide yog qhov zoo tshaj plaws rau sharpening carbide.

Yog tias koj txaus siab rau cov khoom siv tungsten carbide thiab xav paub ntau ntxiv thiab cov ntsiab lus, koj tuaj yeem ua tauTiv tauj peblos ntawm xov tooj los yog xa ntawv ntawm sab laug, los yogXa ntawv rau pebnyob hauv qab ntawm nplooj ntawv no.