Peb Hom Kev Ua Cemented Carbide Rods

Peb hom kev tsimCemented Carbide qws

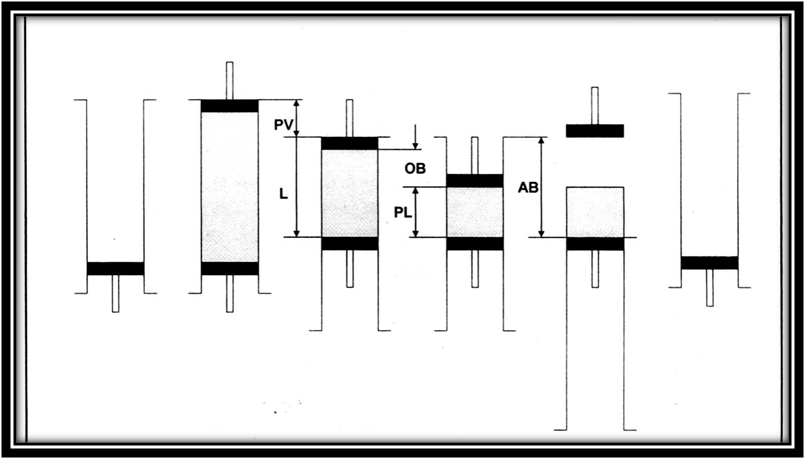

Kev sib sau yog cov txheej txheem maneuverable tshaj plaws hauv kev tsim cov khoom siv tawv tawv, thiab nws yog cov txheej txheem tseem ceeb los xyuas kom meej qhov tseeb thiab pom zoo ntawm cov tawv alloy blanks. Nws yog tus txheej txheem ntawm compacting hmoov rau hauv ib qho khoob nrog cov duab uas xav tau. Nws cov kev cai yooj yim yog kom muaj lub zog thiab qhov loj me.

1. Precision molding

Precision nias yuav tsum tsis tsuas yog muaj cov khoom siv zoo, tab sis kuj zoo software. Tshwj xeeb, nws yuav tsum muaj: siab precision xovxwm (TPA xovxwm), siab precision tuag, siab sib tov, raug nias txheej txheem tsis thiab lwm yam kev mob.

Precision pressing muaj xws li: nias lub voj voog, nias txheej txheem parameter tshuab thiab cov qauv ntawm kev suav, kev xaiv sib tov, nias xaiv, xaiv nkoj, thiab nias zoo, nrog rau cov khoom xa rov qab, thiab lwm yam.

Xovxwm txheej txheem daim duab↓↓↓

2. Extrusion txoj kev

Extrusion molding yog muab cov sib tov rau hauv lub tog raj kheej extrusion tom qab kho plasticizing, tom qab ntawd txhim kho tuag ntawm ib qho kawg ntawm lub tog raj kheej extrusion nrog qhov xav tau ntawm qhov chaw ntawm cov tuag. Ib qho extruder yog ntxig rau ntawm qhov kawg ntawm lub tog raj kheej extruder. Lub siab ntawm extruder yog dhau los ntawm extruder mus rau qhov sib tov, uas dhau los ntawm lub qhov tuag thiab dhau los ua cov khoom zoo li tus.

Nws qhov zoo yog: qhov ntev ntawm cov khoom tsis txwv feem ntau, thiab qhov ntev ntev yog qhov sib txawv dua. Meanwhile, nws feem ntau muaj zog ntau lawm continuation, high efficiency nrog cov cuab yeej yooj yim thiab yooj yim ua hauj lwm.

3. Txias isostatic nias

Txias isostatic siab raws li PASCAL txoj cai; cov hmoov pressed yog kaw nyob rau hauv ib tug elastic pwm nrog ib tug tej yam zoo li thiab loj, thiab ces muab tso rau hauv ib lub thawv kaw high-pressure. Cov kua nruab nrab yog tsav mus rau hauv lub thawv los ntawm lub twj tso kua mis siab, thiab qhov nruab nrab exerts siab sib npaug ntawm txhua qhov chaw ntawm elastic pwm. Cov hmoov nyob rau hauv cov pwm elastic kuj raug sib npaug ntawm lub siab nyob rau hauv tag nrho cov lus qhia thiab nws cov duab yog txo proportionally thaum nws yog ntsia, thiaj li hais tias cov hmoov yog compacted rau hauv ib tug compact dawb paug nrog ib tug tej yam zoo li, loj thiab txaus lub zog.

Sintering

Sintering yog txheej txheem tseem ceeb kawg hauv kev tsim cov cemented carbide. Lub hom phiaj ntawm sintering yog hloov cov porous hmoov compact rau hauv ib qho alloy nrog qee yam qauv thiab cov khoom. Lub sintering ntawm hard alloy yog ntau nyuaj vim lub cev hloov pauv thiab tshuaj lom neeg cov tshuaj tiv thaiv, tab sis feem ntau yog vim lub cev txheej txheem, xws li sintering lub cev densification, carbide grain loj hlob, kev hloov ntawm kev sib raug zoo theem muaj pes tsawg leeg thiab tsim ntawm alloy qauv.

Tag nrho cov txheej txheem sintering tuaj yeem muab faib ua plaub theem:

Waxing pre-burning theem (

Khoom theem sintering theem (800 ℃ - eutectic kub)

Ua kua theem sintering theem (eutectic kub - sintering kub)

Txias theem (sintering kub-chav kub)

Yog tias koj txaus siab rau cov khoom lag luam tungsten carbide thiab xav paub ntau ntxiv thiab cov ntsiab lus, koj tuaj yeem tiv tauj peb hauv xov tooj lossis xa ntawv ntawm sab laug, lossis xa mus rau US MAIL hauv qab ntawm nplooj ntawv no.