Tungsten Carbide Choke Bean Choke Seat Choke Valve for Oil Gas Mining Field Flow Control

Tungsten Carbide Choke Bean Choke Seat Choke Valve for Oil Gas Mining Field Flow Control

In the field of oil and gas extraction, flow control is a key link to ensure safe and efficient production. Tungsten carbide choke beans, choke seats, and choke valves are the core components to achieve this function. They are particularly suitable for harsh working conditions with high pressure, high flow rate, and abrasive media (such as sand and impurities).

I. Core Components and Functions

1. Tungsten Carbide Choke Bean

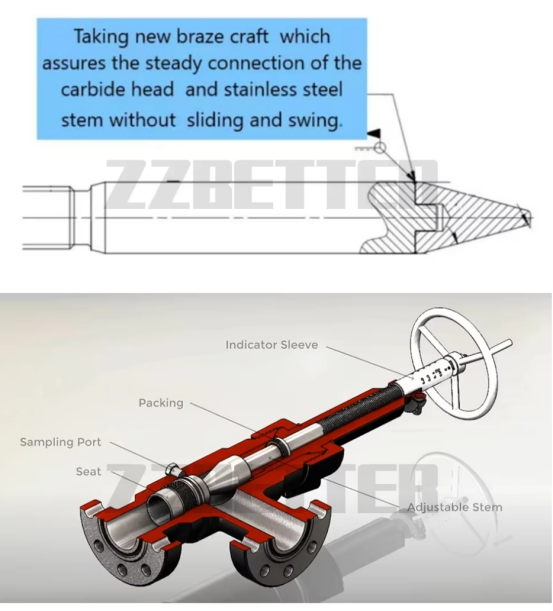

The choke bean is a key flow control component in a throttle valve. It is typically a cylindrical or conical part with a specific aperture, primarily made of tungsten carbide (WC). Tungsten carbide possesses extremely high hardness (close to diamond), wear resistance, and corrosion resistance, making it capable of withstanding the impact and erosion of high-velocity fluids (including sand, gas, and liquid mixtures).

▶ Function: It limits fluid flow by regulating pressure and velocity within the pipeline through the size of its aperture, preventing equipment wear or pressure runaway caused by excessive flow rates.

▶ Feature: Choke beans with different apertures can be replaced according to production needs, providing flexible flow adjustment and adaptability to different operating conditions.

2. Tungsten Carbide Choke Seat

The choke seat is a companion component to the choke bean. It is typically installed inside the throttle valve body, securing the choke bean and forming a seal. It is also made of tungsten carbide to ensure wear resistance and sealing when in contact with the choke bean. Function: Provides stable support for the choke bean and forms a fluid channel with the choke bean, preventing media leakage and ensuring a stable throttling effect. Features: High-precision machined sealing surfaces ensure reliable sealing under high pressure, extending the service life of the entire assembly.

3. Choke Valve

A choke valve is a complete control device that integrates a choke bean, choke seat, valve body, and drive mechanism. It is a key device for regulating flow and pressure in oil and gas production processes (such as wellheads, separators, and oil pipeline manifolds).

▶Function: By changing the flow area between the choke bean and choke seat (or simply replacing the choke bean), it precisely controls fluid flow and pressure. For example, this can reduce wellhead high pressure, regulate media flow into separators, and prevent pipeline overpressure.

▶Categories: Choke valves can be categorized by actuation method as manual, pneumatic, or electric, adapting to production systems with varying degrees of automation.

II. The Core Advantages of Tungsten Carbide Materials

The Choke Bean, Choke Seat, and Choke Valve utilize tungsten carbide as their core material. Tungsten carbide offers exceptional wear resistance, corrosion resistance, high temperature and pressure resistance, and high flow control precision. This makes these components essential for flow control in oil and gas production.

III.Typical Applications

Tungsten carbide choke components (choke beans, choke seats, and choke valves) are widely used in various aspects of oil and gas production:

▶Wellhead systems: Control the flow and pressure of the oil and gas mixture extracted from the bottom of the well, protecting wellhead equipment.

▶Oil and gas separation systems: Regulate the flow of media entering the separator to ensure separation efficiency (e.g., separation of oil, gas, and water).

▶Deep-sea drilling: Due to the high-pressure resistance of tungsten carbide throttle components, they are suitable for deep-sea drilling.

▶Fracturing operations: Control the injection flow and pressure of the fracturing fluid during hydraulic fracturing to ensure effective fracturing.

IV.Conclusion

Tungsten carbide choke beans, choke seats, and choke valves have become indispensable components in modern oil and gas operations due to their extreme wear resistance, high-pressure sealing, and corrosion resistance.