Ego ole ka ị maara gbasara Cutter PDC?

Kedu ihe ị maara maka onye na-egbutu PDC?

Banyere PDC (Polycrystalline Diamond Compact) Cutter

PDC (Polycrystalline Diamond Compact) Cutter bụ ụdị siri ikeihe na-ejikọta polycrystalline diamond na tungsten carbide substrate na oke okpomọkụ na nrụgide.

Ihe mepụtara nke onye na-egbu anụ PDC kpaliri ihe ahụofu-cutter bitn'ihu na ụlọ ọrụ na-egwupụta ihe, echiche ahụ wee ghọọ ewu ewu ozugbo. Ebe ọ bụ naịkpacha ajịomume nke ndị na-egbutu PDC dị irè karịa omume ịkụpịa bọtịnụ ma ọ bụ nha nha, ndị na-egbutu ihe- bita na-achọsi ike.

Na 1982, PDC drill bits nwetara naanị 2% nke ngụkọta ụkwụ agbagoro. N'afọ 2010, 65% nke ngụkọta ebe a gwuruola bụ nke PDC mepụtara.

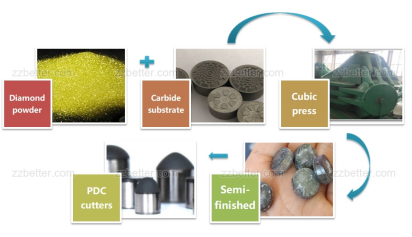

Kedu ka esi eme ndị na-egbutu PDC?

A na-eme ndị na-egbutu PDC site na mkpụrụ osisi tungsten carbide na grit diamond sịntetị. A na-eme ya site na iji ngwakọta nke okpomọkụ dị elu na nrụgide dị elu na ihe na-akpata cobalt alloy iji nyere aka jikọta diamond na carbide n'oge usoro nkwụsịtụ. N'oge usoro jụrụ oyi, tungsten carbide na-agbada na ọnụ ọgụgụ nke 2.5 ngwa ngwa karịa diamond, nke na-ejikọta diamond na Tungsten Carbide ọnụ ma mechaa mepụta PDC Cutter.

Njirimara na ngwa

Ebe ọ bụ na PDC Cutters nwere diamond grit na tungsten carbide substrate, ọ na-ejikọta uru nke ma diamond na tungsten carbide.:

1. High abrasion na-eguzogide ọgwụ

2. High mmetụta na-eguzogide ọgwụ

3. High thermal kwụsie ike

Ugbu a, a na-etinye PDC Cutters n'ebe a na-egwupụta mmanụ, gas na nyocha nke ala, ngwuputa coal, na ọtụtụ ngwa ịkụ ala na igwe nri ndị ọzọ, na-eji ngwá ọrụ dị ka PDC Drill Bits, dị ka Steel PDC Drill Bits & Matrix PDC Drill Bits maka mkpọ mmanụ na Tri-cone PDC Drill Bits maka igwu kol.

Oke

Mmebi mmetụta, mmebi okpomoku, na iyi abrasive niile na-egbochi ịrụ ọrụ olulu mmiri ma nwee ike ime n'ụdị ọdịdị ala dị nro. Agbanyeghị, nhazi kacha sie ike maka ntakịrị PDC ịkụ ala bụ ihe na-emebi emebi.

Nnukwu VS obere cutter

Dị ka a n'ozuzu, nnukwu cutters (19mm ka 25mm) na-eme ihe ike karịa obere cutters. Otú ọ dị, ha nwere ike na-amụba torque mgbanwe. Na mgbakwunye, ọ bụrụ na e mebebeghị BHA ka ijikwa oke iwe, enweghị ntụkwasị obi nwere ike ibute.

E gosipụtara ndị na-egbutu obere (8mm, 10mm, 13mm, na 16mm) ka ha na-egwupụta ROP dị elu karịa ndị na-egbu osisi na ụfọdụ ngwa. Otu ngwa dị otú ahụ bụ nkume nzu.

Ọzọkwa, ibe n'ibe na-ebere na obere cutters ma ọtụtụ n'ime ha nwere ike idi elu mmetụta nbudata.

Na mgbakwunye, obere ndị na-egbutu osisi na-amịpụta obere osisi ebe ndị na-egbutu osisi buru ibu. Nnukwu mbepụ nwere ike ịkpata nsogbu na ihicha oghere ma ọ bụrụ na mmiri mmiri na-egwupụta ihe enweghị ike iburu mkpụ ahụ gbagoro n'afọ.

cutter udi

Ụdị PDC a na-ahụkarị bụ cylinder, akụkụ n'ihi na enwere ike ịhazi ndị na-egbutu cylindrical n'ụzọ dị mfe n'ime mmachi nke profaịlụ ntakịrị nyere iji nweta nnukwu njupụta. Igwe na-ewepu waya eletrọn nwere ike igbutu ma kpụzie tebụl diamond PDC. Ọhụụ na-abụghị planar n'etiti tebụl diamond na mkpụrụ na-ebelata nrụgide fọdụrụnụ. Atụmatụ ndị a na-eme ka iguzogide chipping, spalling, na delamination tebụl diamond. Atụmatụ interface ndị ọzọ na-ebuli nguzogide mmetụta site na ibelata ọkwa nrụgide fọdụrụnụ.