Usoro mmepụta na nhazi usoro nke mkpanaka Carbide cimented

Usoro mmepụta na nhazi usoro nke mkpanaka Carbide cimented

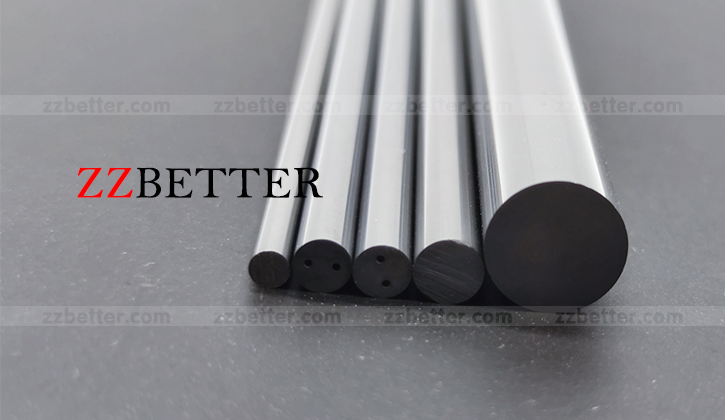

Ogwe carbide e ji ciment emechara bụ mkpanaka gburugburu carbide ejiri ciment. Carbide cimented bụ ihe mejupụtara ihe mejupụtara igwe na-agbagharị agbagharị (usoro siri ike) yana metal bonding (usoro njikọ) nke ntụ ntụ mebere.

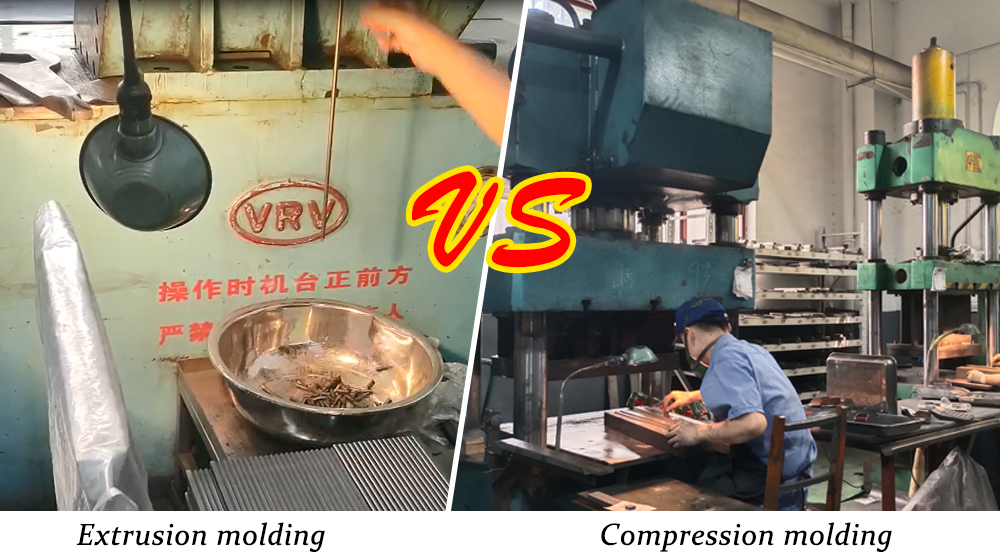

Enwere ụzọ abụọ akpụ maka mkpara gburugburu carbide cimented. Otu ụzọ bụ extrusion akpụ, nke bụ ụzọ kwesịrị ekwesị iji mepụta mkpanaka ogologo ogologo. Ụdị mkpanaka carbide cemented a nwere ike ịbelata ogologo oge ọ bụla onye ọrụ chọrọ n'oge usoro extrusion. Otú ọ dị, n'ozuzu ogologo enweghị ike gafere 350mm. Nke ọzọ bụ mkpakọ ịkpụzi, nke bụ a ụzọ kwesịrị ekwesị maka obere mmanya mmepụta. Dị ka aha ahụ pụtara, a na-agbanye ntụ ntụ carbide simented n'ime ihe.

Alloy ihe na-mere nke refractory metal na a bonding metal site a uzuzu metallurgy usoro. Carbide cimented nwere usoro ihe mara mma dị ka ike siri ike dị elu, nkwụsi ike na-eyi, ike dị mma na ike siri ike, nguzogide okpomọkụ, na nguzogide corrosion. karịsịa elu ya siri ike na iyi nguzogide, nke na-anọgide na-agbanweghị ọbụna na okpomọkụ nke 500 Celsius C, ma ka nwere nnukwu ike na 1000 Celsius. A na-eji Carbide eme ihe n'ọtụtụ ebe dị ka ngwá ọrụ ngwá ọrụ, dị ka ngwá ọrụ ntụgharị, ndị na-egwe ọka, ndị na-emepụta ihe, ihe ọkụkụ, ngwá ọrụ na-agwụ ike, wdg maka ịcha ígwè nkedo, ọla ndị na-adịghị ferrous, plastik, kemịkalụ eriri, graphite, iko, nkume, na ígwè nkịtị. a pụkwara iji ya mee ihe maka igbutu mmiri na-egweri nke ihe siri ike na-arụ ọrụ dị ka ígwè na-eguzogide okpomọkụ, igwe anaghị agba nchara, nnukwu manganese ígwè, ngwá ọrụ ígwè (igwe igwe, ihicha kabinet, Z-ụdị mixer, granulator) ---pịa (ya na nrụgide hydraulic press ma ọ bụ extruder) -- - Sintering (ọkụ degreasing, ọkụ agbakwunyere ma ọ bụ ọkụ ọkụ HIP dị ala)

A na-egweri ihe ndị ahụ mmiri mmiri, nke a mịrị amị, gwakọta ya na gluu mgbe ha nhata, mgbe ahụ a mịrị amị ma na-ebelata nchekasị mgbe a kpụchara ya ma ọ bụ wepụ ya, a na-emepụta oghere alloy ikpeazụ site n'iwepụ na nsị.

Mwepu nke gburugburu mmanya extrusion mmepụta bụ na mmepụta okirikiri dị ogologo. Mwepu nke obere ogwe okirikiri dị n'okpuru 3mm, bepụ nsọtụ abụọ ahụ ga-efunahụ ụfọdụ ihe. Ogologo ogologo nke obere dayameta gburugburu mmanya nke cemented carbide, na-akawanye njọ nke kwụ ọtọ nke oghere. N'ezie, enwere ike imezi nsogbu nke nzizi na okirikiri site na ichigharị cylindrical na ogbo ikpeazụ.

Nke ọzọ bụ mkpakọ ịkpụzi, nke a na-eji na-emepụta obere Ogwe. Dị ka aha ahụ pụtara, e nwere ihe na-akpụ akpụ nke na-akụ ntụ ntụ carbide simenti. Uru nke usoro a na-emepụta carbide cimented: enwere ike ịmepụta ya n'otu oge ma belata n'efu. Mee ka usoro ịkpụ waya dị mfe ma chekwaa okirikiri ihe akọrọ nke usoro extrusion. Oge dị mkpụmkpụ dị n'elu nwere ike ịchekwa ụbọchị 7-10 maka ndị ahịa.

N'ikwu ya n'ụzọ ziri ezi, ịpị isostatic bụkwa nke ịkpụzi. Isostatic pressing bụ ụzọ kacha mma akpụ akpụ maka imepụta ogwe okirikiri carbide buru ibu na ogologo. Site na akara nke pistons dị elu na nke dị ala, mgbapụta nrụgide na-agbanye mmiri mmiri n'etiti cylinder dị elu na rọba na-arụ ọrụ, a na-ebute nrụgide site na rọba na-eme ka a na-eme ka cimented carbide powder press-molded.

Ọ bụrụ na ị nwere mmasị na ngwaahịa tungsten carbide ma chọọ ozi na nkọwa ndị ọzọ, ị nwere ike ịkpọtụrụ anyị site na ekwentị ma ọ bụ mail n'aka ekpe, ma ọ bụ zipu ozi US na ala ibe.