Gịnị bụ Hot Forging

Ịkpụ ọkụ na-ekpo ọkụ na ịhịa aka n'ahụ bụ usoro abụọ dị iche iche maka ịmepụta ígwè na-enye nsonaazụ yiri ya. Onye nrụpụta ga-eleba anya n'ọtụtụ njirisi tupu ị họrọ ụdị nke forging kacha mma maka otu ngwa.

Usoro nke usoro ịhịa aka ọkụ (nke a na-akpọkwa Hot Forming)

Na-ekpo ọkụ na-ekpo ọkụ bụ usoro nke a ghaghị ikpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-emepụta, nke ahụ bụ otú aha "na-ekpo ọkụ na-ekpo ọkụ" si abịa. Nkezi okpomọkụ dị mkpa maka ịgha ọkụ bụ:

Ruo 1150 Celsius maka ígwè

360 ruo 520 Celsius maka Al-Alloys

700 ruo 800 Celsius maka Cu-Alloys

Na-ekpo ọkụ ihe n'oge a na-ekpo ọkụ forging na-ebuli okpomọkụ n'elu recrystallization ebe nke metal. Okpomọkụ dị oke mkpa iji zere nrụrụ nke ígwè siri ike n'oge nrụrụ. Ụdị a na-ekpo ọkụ nke a na-akpọ forging isothermal bara uru iji gbochie oxidation nke ụfọdụ ọla, dị ka superalloys. N'ịkpụ akpụ nke isothermal, usoro a na-eme na ikuku a na-achịkwa nke ukwuu, dịka nke oghere.

Nlebanya na-ekpo ọkụ

Ndị na-emepụta ihe na-ahọrọkarị ihe na-ekpo ọkụ maka mmepụta nke akụkụ ndị nwere mmetụta dị ukwuu na mpaghara nkà na ụzụ. Hot forging na-atụ aro maka deformation nke metal na atụmatụ a elu formability ruru. Atụmatụ ndị ọzọ maka ịhịa aka n'ahụ na-ekpo ọkụ gụnyere:

1. Mmepụta akụkụ pụrụ iche

2. Obere na ọkara ziri ezi

3. Nhazi Ọkwa

4. Obere nrụgide ma ọ bụ obere ọrụ ike

5. Ọdịdị ọka homogenized

6. Ịba ụba ductility

7. Mwepu nke kemịkalụ incongruities

Ọdịmma dị n'ụdị dị ọkụ nwere ike ịdị

Nkwenye ezighi ezi

Enwere ike ịgbagha ihe onwunwe n'oge usoro jụrụ oyi

Usoro ọka ọla dị iche iche

Mmeghachi omume nwere ike ime n'etiti ikuku gbara ya gburugburu na igwe

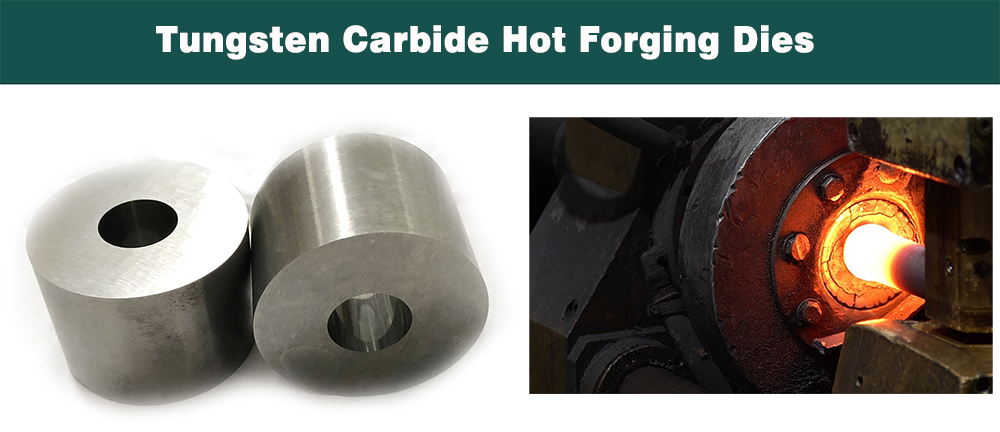

Zhuzhou Better Tungsten Carbide Company bụ tungsten carbide na-eweta maka ihe karịrị afọ 15, anyị na-enye tungsten carbide mkpara, carbide ibe, carbide nwụrụ anwụ, tungsten carbide Ngwuputa bọtịnụ, wdg Ọtụtụ carbide ngwaahịa na-eji na ọnọdụ nke chọrọ elu arụmọrụ na elu kwụsie ike ọbụna na elu okpomọkụ. N'ime ngwaahịa niile, tungsten carbide die nibs ga-abụ oyi-akpụkpọ ma ọ bụ na-ekpo ọkụ na njedebe nke ndị ahịa na-eme ka ọ na-eji jaket mee ka ọ dịkwuo ndụ bara uru nke ngwá ọrụ ahụ. Ịme ihe na-ekpo ọkụ bụ ụzọ dị mkpa iji jikọta carbide die nibs na jaket ígwè n'ime ngwá ọrụ. Ihe ọ bụla a na-achọ na carbide forging anwụ, carbide ịbịaru anwụ oghere, nabata kpọtụrụ anyị.

#tungstencarbide #carbideblank #carbidedie #hotforging #procurement