Advantages of Coating for Carbide Cutting Tools

Advantages of Coating for Carbide Cutting Tools

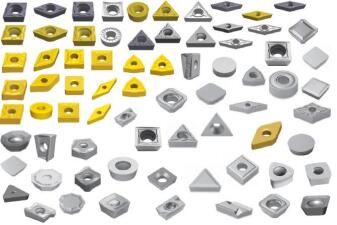

Tungsten carbide cutting tools are the most widely used cutting tools in the machining market, which have significantly increased the productivity level of metal cutting processes, thus significantly reducing the manufacturing costs of everyday items. A variety of advanced coating processes and coating materials are now available in the market.

Carbide inserts with coating have five major advantages as below:

1. Surface gold TiN has the effect of reducing friction and providing wear recognition

2. The special structure of the Al2O3 deposition layer has the best thermal barrier performance to protect the high-speed dry cutting, and the insert substrate resistance to plastic deformation ability.

3. TiCN layer has the performance of anti-abrasive wear, which makes the rear face of the insert have the strongest performance of anti-abrasion.

4. Using gradient sintering technology, the impact resistance and wear resistance of the cutting edge are enhanced, thus improving the anti-breaking ability of the cutting edge.

5. Contains carbide with a special crystal structure, which improves the red hardness of the carbide tip matrix and strengthens the high-temperature resistance of the insert.

End mills with coating have five major advantages as below:

1. Good mechanical and cutting performance: The coated metal cutting tools combine the excellent performance of the base material and the coating material, which not only maintains the good toughness and high strength of the base but also has the high hardness, high wear resistance and low resistance of the coating, coefficient of friction. Therefore, the cutting speed of the coated tool can be increased by more than 2 times that of the uncoated tool. A higher feed rate is allowed, and its life has also been improved.

2. Strong versatility: The coated tools have wide versatility, and the processing range is significantly expanded. One type of coated tool can replace several types of uncoated tools.

3. Thickness of coating: The tool life will increase with the increase of coating thickness, but when the coating thickness reaches saturation, the tool life will no longer increase significantly. When the coating is too thick, it is easy to cause peeling; when the coating is too thin, the wear resistance is poor.

4. Regrindability: poor refundability of coated blades, complex coating equipment, high process requirements, and long coating time.

5. Coating materials: cutting tools with different coating materials have different cutting performances. When cutting at high speed, TiN is more suitable.

If you are interested in tungsten carbide products and want more information and details, you can CONTACT US by phone or mail at the left, or SEND US MAIL at the bottom of the page.