How to Choose the Best End Mill

How to Choose the Best End-Mill

End mills are essential tools used in milling operations to cut and shape various materials, such as metal, wood, and plastics. The quality of an end mill greatly affects the machining results, tool life, and overall productivity. How to get the best and most suitable end mill? In this article, we will discuss the key factors to consider when selecting an end mill manufacturer and quality criteria of an end mill.

End mills are essential tools used in milling operations to cut and shape various materials, such as metal, wood, and plastics. The quality of an end mill greatly affects the machining results, tool life, and overall productivity. How to get the best and most suitable end mill? In this article, we will discuss the key factors to consider when selecting an end mill manufacturer and quality criteria of an end mill.

How to Choose an End Mill Manufacturer?

Choosing the right end mill manufacturer is crucial to ensure the quality, performance, and longevity of these cutting tools.

1. Reputation and Experience:

One of the first factors to consider is the manufacturer's reputation and experience in the industry. Look for manufacturers with a proven track record of producing high-quality end mills. Consider their years of experience, certifications, and customer reviews. A reputable manufacturer is more likely to provide reliable and durable end mills.

2. Manufacturing Capabilities:

It is important to understand the manufacturing capabilities of the end mill manufacturer. Look for manufacturers that have advanced machinery, state-of-the-art facilities, and a strong commitment to quality control. A manufacturer with in-house capabilities for designing, grinding, and coating end mills can offer better control over the quality and performance of the tools.

3. Material Selection and Coatings:

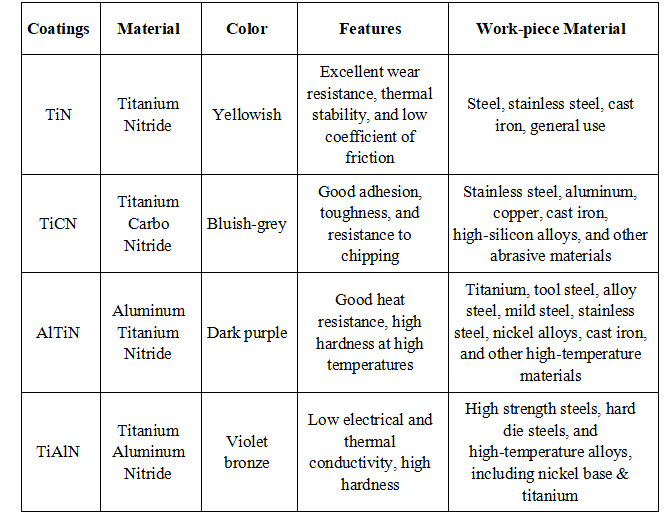

Consider the range of materials offered by the manufacturer for end mills. Different materials, such as high-speed steel (HSS), carbide, and cobalt, have different properties and performance characteristics. A good manufacturer should offer a variety of materials to cater to different machining needs. Additionally, inquire about the availability of various coatings, such as TiN, TiAlN, and DLC, which enhance the tool's durability and performance.

4. Customization Options:

Every machining application has its unique requirements. A reliable end mill manufacturer should offer customization options to meet specific needs. This could include custom tool geometries, special coatings, or modified tool lengths. A manufacturer with the ability to customize end mills can provide tailored solutions that optimize performance and productivity.

5. Technical Support and Customer Service:

Consider the level of technical support and customer service provided by the manufacturer. A good manufacturer should have knowledgeable experts who can offer guidance on tool selection, usage, and troubleshooting. Look for manufacturers that offer prompt and responsive customer service to address any concerns or issues that may arise.

6. Price and Value:

While price is an important consideration, it should not be the sole determining factor. Cheaper end mills may initially save money, but they may lack durability and performance. Look for manufacturers that offer competitive pricing while delivering good value for the quality and performance of their end mills. Consider the overall cost per tool and the expected tool life to make an informed decision.

Choosing the right end mill manufacturer is crucial for achieving optimal machining results. Consider factors such as reputation, experience, manufacturing capabilities, material selection, customization options, technical support, and price. By carefully evaluating these factors, you can select a reliable manufacturer that offers high-quality end mills, ensuring efficiency, precision, and longevity in your milling operations.

How to Judge the Quality of an End Mill?

1. Material Quality:

The first aspect to consider is the material used to manufacture the end mill. High-quality end mills are typically made from materials such as carbide or high-speed steel (HSS). Carbide end mills are known for their exceptional hardness and wear resistance, making them suitable for demanding machining applications. HSS end mills offer good toughness and are cost-effective for less demanding applications. Check the manufacturer's specifications to ensure the end mill is made from a high-quality material that suits your machining needs.

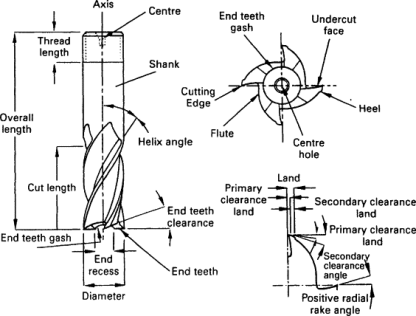

2. Manufacturing Precision:

The precision with which an end mill is manufactured significantly impacts its performance. Look for end mills that are produced with tight tolerances and high precision. Check for signs of precision in the tool's design, such as symmetrical flutes, accurately ground cutting edges, and precise dimensions. A well-manufactured end mill will have consistent geometry throughout the tool, ensuring accurate and repeatable machining results.

3. Coating Quality:

Coatings applied to end mills enhance their performance by reducing friction, increasing hardness, and improving chip evacuation. High-quality end mills are often coated with materials such as titanium nitride (TiN), titanium aluminum nitride (TiAlN), or diamond-like carbon (DLC). When judging the quality of an end mill, inspect the coating for uniformity, smoothness, and adhesion. A high-quality coating will be evenly applied, free from defects, and have good adhesion to the tool's surface.

Some of the basic coatings of end mills

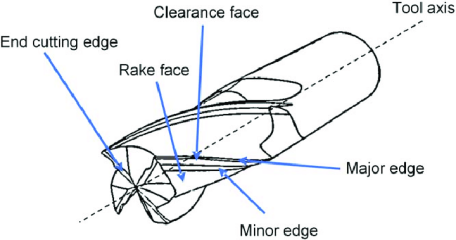

4. Cutting Edge Strength and Sharpness:

The cutting edge of an end mill is critical for achieving precise and efficient cutting. Examine the cutting edge under magnification to assess its strength and sharpness. A high-quality end mill will have a sharp cutting edge that is free from chips or nicks. The cutting edge should also exhibit good strength and resistance to wear, ensuring prolonged tool life and consistent cutting performance.

5. Chip Evacuation:

Efficient chip evacuation is crucial for preventing chip buildup and improving the overall performance of an end mill. Look for end mills with well-designed flutes that allow for smooth chip evacuation. The flutes should have proper spacing, depth, and shape to facilitate the easy removal of chips from the cutting area. End mills with effective chip evacuation capabilities help prevent tool overload, heat buildup, and premature tool failure.

6. Performance and Tool Life:

The ultimate judge of an end mill's quality is its performance and tool life. Evaluate the end mill's ability to achieve precise cuts, maintain sharpness, and provide consistent results. Consider the tool life and how well the end mill retains its cutting performance over time. High-quality end mills will exhibit longer tool life, reduced tool wear, and consistent performance, resulting in improved productivity and cost-effectiveness.

Judging the quality of an end mill requires careful evaluation of multiple factors, including material quality, manufacturing precision, coating quality, cutting edge strength and sharpness, chip evacuation capabilities, and overall performance. By considering these factors, you can select high-quality end mill.

If you are interested in the tungsten carbide studs and want to get more information, please Contact US by the phone number or email at the left or Send Us Mail at the bottom of the page.