Common Metal Surface Chithandizo

Common Metal Surface Chithandizo

Lingaliro la chithandizo chachitsulo pamwamba

Zimatanthawuza njira yosinthira mawonekedwe ndi mawonekedwe a gawo ndikuwongolera kuphatikiza kwake ndi zinthu za masanjidwewo kuti zikwaniritse zofunikira zomwe zidakonzedweratu pogwiritsa ntchito matekinoloje atsopano mufizikiki yamakono, chemistry, zitsulo, ndi njira zochizira kutentha.

1. Kusintha kwa Metal Surface

Muli njira izi: pamwamba kuuma, sandblasting, knurling, kujambula waya, kupukuta, laser pamwamba kuumitsa

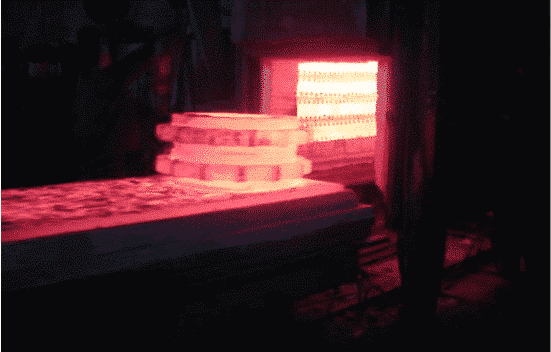

(1) kuuma kwachitsulo pamwamba

Ndi njira yochizira kutentha yomwe imapangitsa kuti pamwamba pake isungunuke ndikuzizira mofulumira kuti iwumitse pamwamba popanda kusintha mankhwala achitsulo.

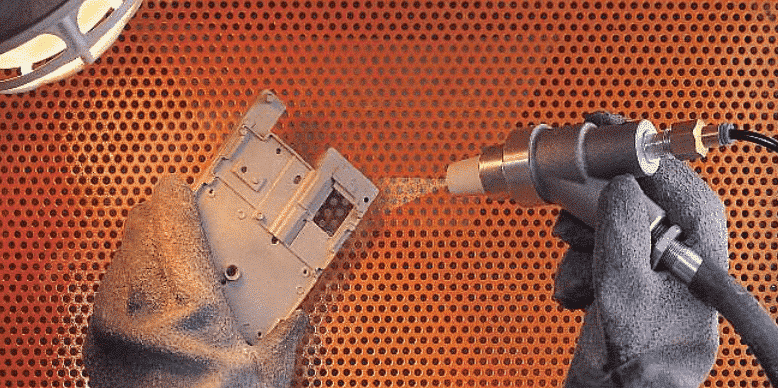

(2) pamwamba pazitsulo zachitsulo

The workpiece pamwamba amakhudzidwa ndi mkulu-liwiro mchenga ndi chitsulo particles, amene angagwiritsidwe ntchito kusintha makina katundu wa gawo ndi kusintha dziko. Opaleshoniyi imatha kusintha mphamvu zamakina, kukana komanso kuthetsa kupsinjika kotsalira.

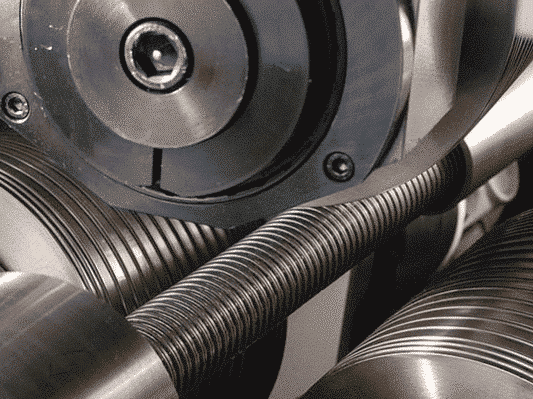

(3) kugudubuza kwachitsulo pamwamba

Ndiko kukanikiza pamwamba pa workpiece ndi chodzigudubuza cholimba kutentha kutentha kotero kuti pamwamba pa workpiece akhoza kuumitsa ndi pulasitiki deformation kuti kupeza yolondola ndi yosalala pamwamba.

(4) Pamwamba pazitsulo

Pansi pa mphamvu yakunja, chitsulo chimakakamizika kupyolera mukufa. Chigawo chamtanda chachitsulo chimaponderezedwa kuti chisinthe mawonekedwe ake ndi kukula kwake. Njira imeneyi imatchedwa kujambula waya. Malinga ndi zofunikira zokongoletsa, kujambula kwa waya kumatha kupangidwa kukhala ulusi wosiyanasiyana, monga wowongoka, wopindika, wavy, ndi ulusi.

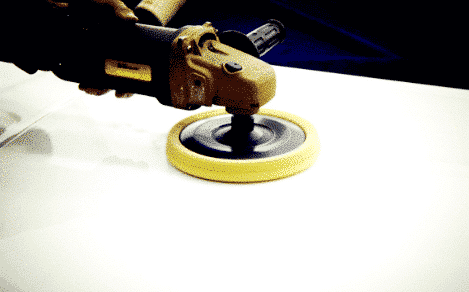

(5) kupukuta kwachitsulo pamwamba

Kupukuta ndi njira yomaliza yosinthira pamwamba pa gawo. Ikhoza kungopeza malo osalala popanda kuwongolera kulondola kwa makina. Mtengo wa Ra wa pamwamba wopukutidwa ukhoza kufika ku 1.6-0.008 um.

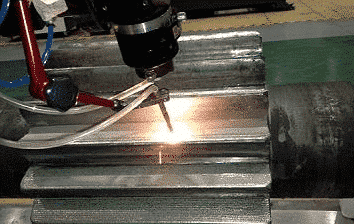

(6) Laser kulimbitsa zitsulo pamwamba

Mtsinje wa laser wokhazikika umagwiritsidwa ntchito kutenthetsa chogwirira ntchito mwachangu ndiyeno kuziziritsa mwachangu chogwiriracho kuti chikhale cholimba komanso cholimba. Kulimbitsa pamwamba pa laser kuli ndi ubwino wopindika pang'ono, kugwira ntchito kosavuta, ndi kulimbikitsa kwanuko.

2. Metal Surface Alloying Technology

Mwa njira zakuthupi, zida zowonjezera zimawonjezeredwa ku matrix kuti apange wosanjikiza wa alloy. Carburizing wamba ndi nitriding ndi mwa njira iyi. Imayika chitsulo ndi cholowetsamo mu chipinda chosindikizidwa chomwecho, imayendetsa zitsulo pamwamba pa kutentha kwa vacuum, ndikupanga carbon ndi nitrogen kulowa muzitsulo zachitsulo monga ma atomu kuti akwaniritse cholinga cha alloying.

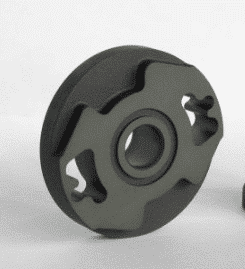

(1) Kudetsa: Kanema wakuda kapena wabuluu wa okusayidi amapangidwa kuti alekanitse mpweya ku dzimbiri la chogwirira ntchito.

(2) phosphating: Njira yochizira zitsulo zamagetsi zamagetsi zomwe zimagwiritsidwa ntchito kuteteza zitsulo zoyambira poyika ma phosphates oyera, osasungunuka m'madzi pamwamba pa zida zomizidwa mu yankho la phosphating.

Palibe wa iwo amakhudza dongosolo mkati mwa workpiece. Kusiyana kwake ndikuti chitsulo chakuda chimapangitsa chogwirira ntchito kukhala chonyezimira, pomwe phosphating imawonjezera makulidwe ndikuwumitsa pamwamba pa chogwiriracho. Phosphating imateteza kwambiri kuposa yakuda. Pankhani ya mtengo, mdima wakuda nthawi zambiri umakhala wokwera mtengo kuposa phosphating.

(3)ukadaulo wokutira wazitsulo pamwamba

Chophimba kapena chophimba chimapangidwa pamwamba pa gawo lapansi ndi njira za physicochemical. Amagwiritsidwa ntchito kwambiri pazida zodulira carbide.

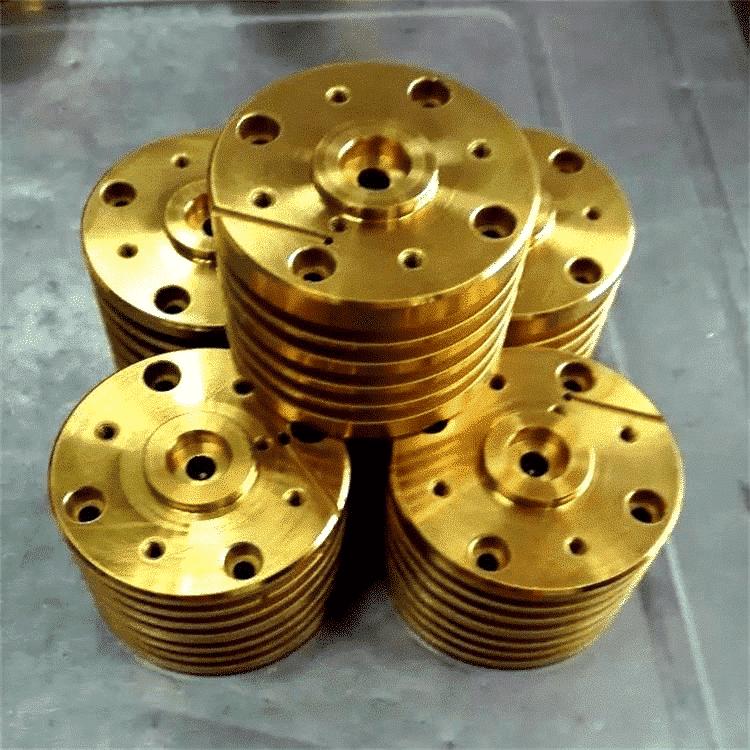

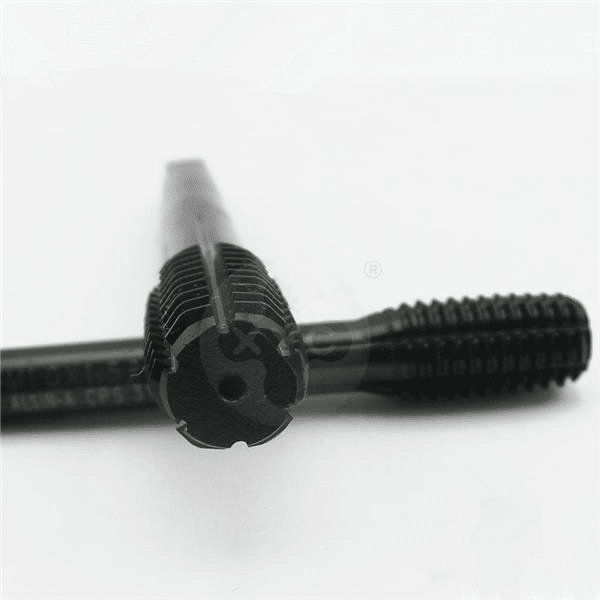

Kupaka kwa TiN ndi zokutira kwa TiCN pamwamba pazitsulo

Tini wokhuthala pang'ono Pa zida zodulira zomwe zimadula mkuwa wofewa kapena chitsulo chofewa, zinthuzo nthawi zambiri zimakhala zagolide.

Zovala zakuda za titaniyamu nitride nthawi zambiri zimagwiritsidwa ntchito pomwe kugundana kumakhala kochepa koma kuuma kumafunika.

Zomwe zili pamwambazi ndizofotokozera mwachidule za chithandizo chazitsulo pamwamba pazitsulo. Ngati muli ndi chidwi ndi zinthu za tungsten carbide ndipo mukufuna zambiri ndi zambiri, mutha KULUMIKIZANA NAFE pa lamya kapena makalata kumanzere, kapena KUTITUMIZIRA MAIL pansi pa tsambali.