Terminology of hard alloy(1)

Terminology of hard alloy(1)

Kupititsa patsogolo kumvetsetsa kwa malipoti ndi zolemba zaukadaulo za hard alloy, kulinganiza mawu, ndikufotokozera tanthauzo la mawu aukadaulo muzolemba, tili pano kuti tiphunzire mawu a hard alloy.

Tungsten Carbide

Tungsten carbide amatanthauza zophatikizika za sintered zomwe zimakhala ndi ma carbides achitsulo osakanizika ndi zomangira zitsulo. Pakati pazitsulo zachitsulo zomwe zikugwiritsidwa ntchito panopa, tungsten carbide (WC), titanium carbide (TiC), ndi tantalum carbide (TaC) ndizomwe zimagwiritsidwa ntchito kwambiri. Chitsulo cha Cobalt chimagwiritsidwa ntchito kwambiri popanga simenti ya carbide ngati chomangira. Pazinthu zina zapadera, zomangira zitsulo monga faifi tambala (Ni) ndi chitsulo (Fe) zitha kugwiritsidwanso ntchito.

Kuchulukana

Kachulukidwe amatanthauza kuchuluka kwa misa ndi voliyumu ya zinthu, zomwe zimatchedwanso mphamvu yokoka yeniyeni. Voliyumu yake imakhalanso ndi kuchuluka kwa pores muzinthuzo. Tungsten carbide (WC) ili ndi kachulukidwe ka 15.7 g/cm³ ndipo cobalt (Co) imakhala ndi makulidwe a 8.9 g/cm³. Choncho, pamene cobalt (Co) zomwe zili mu tungsten-cobalt alloys (WC-Co) zimachepa, kachulukidwe chonsecho chidzawonjezeka. Ngakhale kuchuluka kwa titanium carbide (TiC) kumakhala kochepa kuposa kwa tungsten carbide, ndi 4.9 g/cm3 yokha. Ndi mankhwala ena azinthu zakuthupi, kuwonjezeka kwa pores muzinthu kumabweretsa kuchepa kwa kachulukidwe.

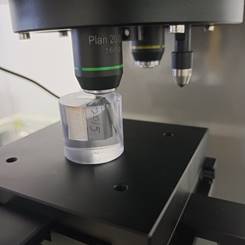

Kuuma

Kuuma kumatanthauza kuthekera kwa chinthu kukana kupunduka kwa pulasitiki.

Vickers hardness (HV) imagwiritsidwa ntchito kwambiri padziko lonse lapansi. Njira yoyezera kuuma imeneyi imatanthawuza kuuma kwa mtengo wopezedwa pogwiritsa ntchito diamondi kuti alowe pamwamba pa chitsanzo kuti ayese kukula kwa indentation pansi pa katundu wina. Rockwell hardness (HRA) ndi njira ina yoyezera kuuma yomwe imagwiritsidwa ntchito. Imagwiritsa ntchito kuya kwa kondomu yokhazikika ya diamondi kuyeza kuuma. Kuuma kwa Vickers ndi kuuma kwa Rockwell kungagwiritsidwe ntchito poyezera kuuma kwa carbide yopangidwa ndi simenti, ndipo awiriwa amatha kusinthidwa kukhala wina ndi mnzake.

Mphamvu yopindika

Mphamvu yopindika imadziwikanso ngati mphamvu yopindika yodutsa kapena mphamvu yopindika. Ma alloys olimba amawonjezedwa ngati mtengo wosavuta wothandizira pa ma pivots awiri, ndiyeno katundu umayikidwa pakatikati pa ma pivots onse mpaka alloy yolimba itaphulika. Miyezo yowerengedwa kuchokera ku ndondomeko yokhotakhota imagwiritsidwa ntchito pa katundu wofunika kuti athyole, ndi gawo la gawo lachitsanzo. Mu ma aloyi a tungsten-cobalt (WC-Co), mphamvu yosunthika imawonjezeka ndi cobalt (Co) zomwe zili mu ma aloyi a tungsten-cobalt, koma mphamvu yosunthika imafika pachimake pamene cobalt (Co) ikufika pafupifupi 15%. Mphamvu ya Flexural imayesedwa poyesa miyeso ingapo. Mtengowu udzasiyananso ndi geometry yachitsanzo, mawonekedwe a pamwamba (kusalala), kupsinjika kwamkati, ndi zolakwika zamkati zazinthu. Choncho, mphamvu zowonongeka ndizochepa chabe za mphamvu, ndipo mphamvu zowonongeka sizingagwiritsidwe ntchito ngati maziko a kusankha zinthu.

Porosity

Simenti carbide amapangidwa ndi ufa zitsulo ndondomeko ndi kukanikiza ndi sintering. Chifukwa cha chikhalidwe cha njira, kufufuza kuchuluka kwa porosity akhoza kukhala mu zitsulo dongosolo la mankhwala.

Kuchepetsa porosity kumatha kupititsa patsogolo magwiridwe antchito onse azinthu. Pressure sintering process ndi njira yabwino yochepetsera porosity.