Zofunika zokutira mitundu ya mapeto mphero

Mitundu yoyambira ya zokutira mapeto

The carbide end mill imadziwikanso kuti cemented carbide end mill. Kuuma kwa chida chokha nthawi zambiri kumakhala pakati pa HRA88-96 madigiri. Koma ndi zokutira pamwamba, kusiyana kumabwera. Njira yotsika mtengo kwambiri yopititsira patsogolo magwiridwe antchito a mphero ndikuwonjezera zokutira zoyenera. Ikhoza kuwonjezera moyo wa chida ndi ntchito.

Kodi zomatira za end mill pamsika ndi zotani?

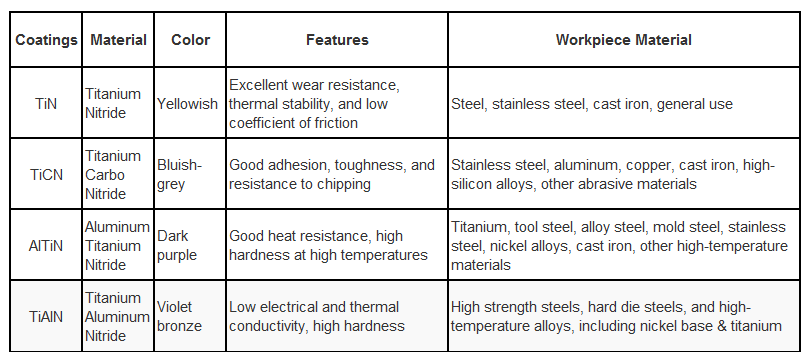

1.TiN - Titanium Nitride - zomatira zosagwirizana ndi mavalidwe anthawi zonse

TiN ndiye chotchinga cholimba chomwe chimavalira komanso chosamva ma abrasion. Imachepetsa kukangana, imawonjezera kukhazikika kwamankhwala ndi kutentha komanso imachepetsa kumamatira kwazinthu zomwe zimachitika nthawi zambiri popanga zitsulo zofewa. TiN ndi yoyenera kupaka zida zopangidwa ndi simenti ya carbides- kubowola, zodulira mphero, zida zodulira, matepi, ma reamers, mipeni, zida zodulira, zida zometa ndi zopindika, matrices, mafomu, ndi zina zambiri. zigwiritsidwe ntchito pazida zamankhwala (opaleshoni ndi mano) ndi zida zolumikizidwa. Chifukwa cha kamvekedwe kake ka golide, TiN yapeza kugwiritsidwa ntchito kwambiri ngati zokutira zokongoletsa. Chophimba cha TiN chogwiritsidwa ntchito chimachotsedwa mosavuta kuzitsulo zachitsulo. Kukonzanso kwa zida kumatha kuchepetsa mtengo makamaka pogwiritsa ntchito zida zodula.

2.TiCN - Titanium Carbo-Nitride - kuvala zokutira zosagwira motsutsana ndi dzimbiri zomatira

TiCN ndiyabwino kwambiri pazolinga zonse. TiCN ndi yolimba komanso yosamva mphamvu kuposa TiN. Itha kugwiritsidwa ntchito kuvala zida zodulira, nkhonya ndi kupanga zida, zida za jekeseni wa nkhungu ndi zida zina zobvala. Popeza ndi biocompatible, itha kugwiritsidwa ntchito pazida zamankhwala ndi zida zoyika. Kuthamanga kwa makina kumatha kuonjezedwa ndipo moyo wa chida ukhoza kukulitsidwa ndi 8x pakudalira kugwiritsa ntchito, kuziziritsa ndi zinthu zina zamakina. Chophimba cha TiCN chikulimbikitsidwa kuti chigwiritsidwe ntchito podula mokwanira bwino chifukwa cha kutsika kwake kwa kutentha. Chophimba cha TiCN chomwe chinagwiritsidwa ntchito chimavulidwa mosavuta ndipo chida chimakutidwanso. Kukonzanso zida zodula kumatha kuchepetsa kwambiri ndalama.

TiCN ndiyabwino kwambiri pazolinga zonse. TiCN ndi yolimba komanso yosamva mphamvu kuposa TiN. Itha kugwiritsidwa ntchito kuvala zida zodulira, nkhonya ndi kupanga zida, zida za jekeseni wa nkhungu ndi zida zina zobvala. Popeza ndi biocompatible, itha kugwiritsidwa ntchito pazida zamankhwala ndi zida zoyika. Kuthamanga kwa makina kumatha kuonjezedwa ndipo moyo wa chida ukhoza kukulitsidwa ndi 8x pakudalira kugwiritsa ntchito, kuziziritsa ndi zinthu zina zamakina. Chophimba cha TiCN chikulimbikitsidwa kuti chigwiritsidwe ntchito podula mokwanira bwino chifukwa cha kutsika kwake kwa kutentha. Chophimba cha TiCN chomwe chinagwiritsidwa ntchito chimavulidwa mosavuta ndipo chida chimakutidwanso. Kukonzanso zida zodula kumatha kuchepetsa kwambiri ndalama.

3. Chophimba cha aluminium-titanium-nitride (AlTiN)

Ndi mankhwala a zinthu zitatu zo aluminiyamu, titaniyamu, ndi nayitrogeni. Kukhuthala kwa zokutira kuli pakati pa 1-4 ma micrometer (μm).

Mbali yapadera ya zokutira za AlTiN ndizovuta kwambiri kupirira kutentha ndi okosijeni. Izi ndi zina chifukwa cha kuuma kwa nano kwa 38 Gigapascal (GPa). Zotsatira zake, zomatira ngakhale zimathamanga kwambiri ndi kutentha kocheperako sikukhazikika. Poyerekeza ndi zida zopanda zokutira, zokutira za AlTiN, malingana ndi kagwiritsidwe ntchito, zimawonjezera moyo wautumiki kuwirikiza kakhumi ndi zinayi.

Chokutira chokhala ndi aluminiyamu kwambiri ndi choyenera kwambiri pazida zolondola, zomwe zimadula zinthu zolimba monga mwachitsanzo. chitsulo (N/mm²)

Kutentha kwakukulu kwa ntchito ndi 900° Celcius (pafupifupi 1,650° Fahrenheit) ndipo poyerekeza ndi TiN yokutira yosamva kutentha kwa 300° Celcius.

Kuziziritsa sikofunikira. Mwambiri, komabe, kuziziritsa kumawonjezera moyo wautumiki wa chida.

Monga tanenera pa zokutira za TiAlN zambiri tiyenera kudziŵika kuti zokutira ndi chitsulo chachitsulo ziyenera kukhala zoyenera kugwiritsa ntchito muzinthu zolimba. Ichi ndichifukwa chake tavala zobowola zapadera zopangidwa ndi tungsten-carbide ndi AlTiN.

4.TiAlN - Titanium Aluminium Nitride - kuvala zokutira zosagwira chifukwa chodula kwambiri

TiAlN ndi zokutira zolimba kwambiri komanso kukana kwamafuta ambiri komanso okosijeni. Kuphatikizika kwa aluminiyamu kunapangitsa kuti kutenthedwa kwa matenthedwe kwa PVD yaphatikizidwe iyi potengera zokutira wamba wa TiN ndi 100 ° C. TiAlN imakhala yokutidwa pazida zodula kwambiri zomwe zimagwiritsidwa ntchito pamakina a CNC popanga zinthu zolimba kwambiri komanso pamikhalidwe yodula kwambiri. TiAlN ndiyoyenera makamaka kwa odula zitsulo zolimba za monolithic, kubowola, zida zodulira ndi mipeni yopangira. Itha kugwiritsidwa ntchito pamakina owuma kapena pafupi ndi makina owuma.

TiAlN ndi zokutira zolimba kwambiri komanso kukana kwamafuta ambiri komanso okosijeni. Kuphatikizika kwa aluminiyamu kunapangitsa kuti kutenthedwa kwa matenthedwe kwa PVD yaphatikizidwe iyi potengera zokutira wamba wa TiN ndi 100 ° C. TiAlN imakhala yokutidwa pazida zodula kwambiri zomwe zimagwiritsidwa ntchito pamakina a CNC popanga zinthu zolimba kwambiri komanso pamikhalidwe yodula kwambiri. TiAlN ndiyoyenera makamaka kwa odula zitsulo zolimba za monolithic, kubowola, zida zodulira ndi mipeni yopangira. Itha kugwiritsidwa ntchito pamakina owuma kapena pafupi ndi makina owuma.