Mitundu Itatu Yopanga Ndodo Za Cemented Carbide

Mitundu Itatu YopangaZopangira Simenti za Carbide

Kupanga ndiye njira yosinthika kwambiri popanga aloyi yolimba, ndipo ndi njira yofunika kwambiri yowonetsetsa kulondola komanso kowoneka bwino kwa zitsulo zolimba zolimba. Ndi njira yophatikizira ufa kukhala wopanda kanthu ndi mawonekedwe omwe mukufuna. Zofunikira zake ndizofunikira kukhala ndi mphamvu inayake ndi kukula kwake.

1. Kuumba mwatsatanetsatane

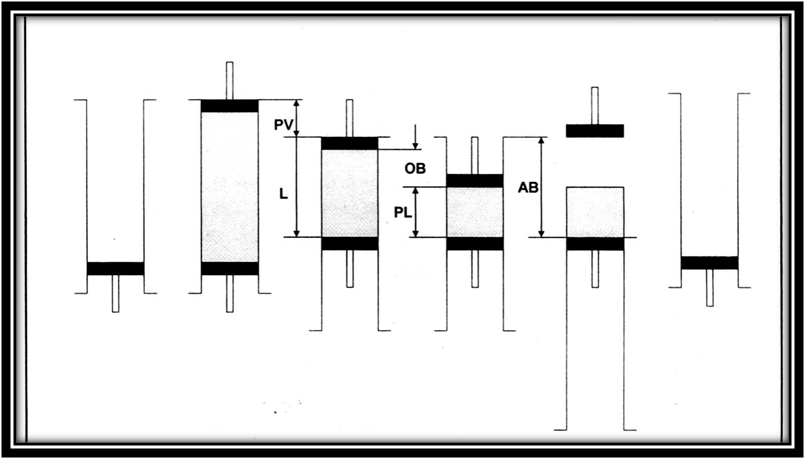

Kukanikiza mwatsatanetsatane sikuyenera kukhala ndi zida zabwino zokha, komanso mapulogalamu abwino. Mwachindunji, ndikofunikira kukhala ndi: makina osindikizira apamwamba kwambiri (TPA press), kufa kwapamwamba kwambiri, kusakaniza kwakukulu kwa ntchito, ndondomeko yolondola yosindikizira ndi zina zofunika.

Kukanikiza mwatsatanetsatane kumaphatikizapo: kukanikiza kozungulira, kukanikiza makina a parameter ndi miyeso yowerengera, kusankha kosakaniza, kukanikiza kusankha kwakufa, kusankha mabwato, ndikukankhira khalidwe, komanso kukonzanso zinthu, etc.

Kukanikiza Njira Chithunzi↓↓↓

2. Extrusion kupanga

Extrusion akamaumba ndi kuika osakaniza mu yamphamvu extrusion pambuyo plasticizing mankhwala, ndiye khazikitsa amafa pa mapeto a yamphamvu extrusion ndi mabowo ankafuna padziko amene amafa. An extruder anaikapo pa mapeto ena a extruder yamphamvu. Kupanikizika kwa extruder kumadutsa mu extruder kupita kusakaniza, komwe kumadutsa mu dzenje lakufa ndikukhala chinthu chopangidwa.

Ubwino wake ndi: kutalika kwa mankhwalawa sikuletsedwa mwachizolowezi, ndipo kutalika kwa nthawi yayitali kumakhala kofanana. Pakadali pano, nthawi zambiri imakhala ndi kupitilirabe kwamphamvu yopanga, kuyendetsa bwino kwambiri ndi zida zosavuta komanso ntchito yabwino.

3. Kuzizira kwa isostatic kukanikiza

Cold isostatic pressure imachokera pa mfundo ya PASCAL; ufa woponderezedwa umasindikizidwa mu nkhungu zotanuka ndi mawonekedwe ndi kukula kwake, kenaka amaikidwa mu chidebe chotsekedwa chapamwamba. Sing'anga yamadzimadzi imayendetsedwa mu chidebe kudzera pa pampu yothamanga kwambiri, ndipo sing'angayo imagwira ntchito mofanana pamtundu uliwonse wa nkhungu zotanuka. Ufa mu nkhungu zotanuka umakhalanso pansi pa kukakamizidwa kofanana kumbali zonse ndipo mawonekedwe ake amachepetsedwa mofanana pamene aikidwa, kotero kuti ufawo umakhala wosasunthika ndi mawonekedwe enaake, kukula kwake ndi mphamvu zokwanira.

Sintering

Sintering ndiye njira yayikulu yomaliza popanga simenti ya carbide. Cholinga cha sintering ndikusintha porous ufa yaying'ono kukhala aloyi ndi zina kapangidwe ndi katundu. The sintering wa aloyi zolimba ndi zovuta kwambiri chifukwa cha kusintha kwa thupi ndi zochita mankhwala, koma makamaka chifukwa cha ndondomeko thupi, monga sintering thupi kachulukidwe, carbide mbewu kukula, kusintha komangira gawo zikuchokera ndi mapangidwe aloyi dongosolo.

Njira yonse yopangira sintering imatha kugawidwa m'magawo anayi:

Waxing pre-burning stage (

Gawo lolimba la sintering (800 ℃- kutentha kwa eutectic)

Liquid phase sintering stage (kutentha kwa eutectic - sintering kutentha)

Malo ozizira (kutentha kwa sintering-chipinda cha chipinda)

Ngati mukufuna zambiri zamtundu wa tungsten carbide ndipo mukufuna zambiri ndi zambiri, mutha KULUMIKIZANA NAFE pa lamya kapena makalata kumanzere, kapena TITUMIZENI MAIL pansi pa tsambali.