Kodi Tungsten Carbide Studs Kwa HPGR Ndi Chiyani?

Kodi Tungsten Carbide Studs Kwa HPGR Ndi Chiyani?

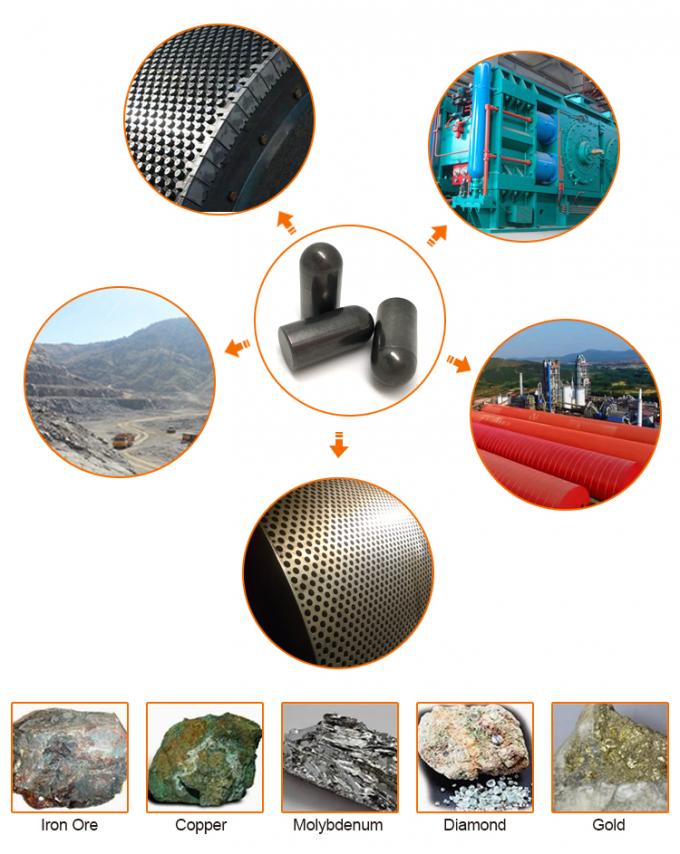

Ma tungsten carbide studs amatchedwanso cemented carbide studs, mabatani a carbide, ndi malangizo a carbide, omwe amagwiritsidwa ntchito kwambiri pogaya zodzigudubuza kwambiri. Makapu a Carbide amagwiritsidwa ntchito pogaya chopukutira chothamanga kwambiri pophwanya zida za simenti, clinker, iron ore, mkuwa, diamondi, ndi quartz. Nthawi ya moyo imatha kufika maola 8000-30000 molingana ndi magiredi osiyanasiyana ndi ntchito zosiyanasiyana.

Simenti za carbide studs monga gawo loyambira la vertical impact crusher (zipangizo zamchenga) zimagwiritsidwa ntchito kwambiri mumigodi, mchenga ndi miyala, simenti, zitsulo, uinjiniya wa hydropower, ndi mafakitale ena, omwe amapempha kuti zinthu zisawonongeke mwachangu komanso kukana kuvala mwamphamvu. , komanso kugwiritsa ntchito simenti ya carbide ndi chisankho chabwino. High-Pressure Grinding Roller ndi zida zophwanya mphamvu zamaukadaulo atsopano. Kuchita kwapamwamba kwa carbide stud kumakulitsa moyo wa High-Pressure Grinding Roller. ZZBETTER imapereka zipilala zama carbide zokhala ndi kukana kwabwino kovala komanso kulimba kwamphamvu kwambiri, zomwe zimatha kukwaniritsa zofunikira zamitundu yosiyanasiyana.

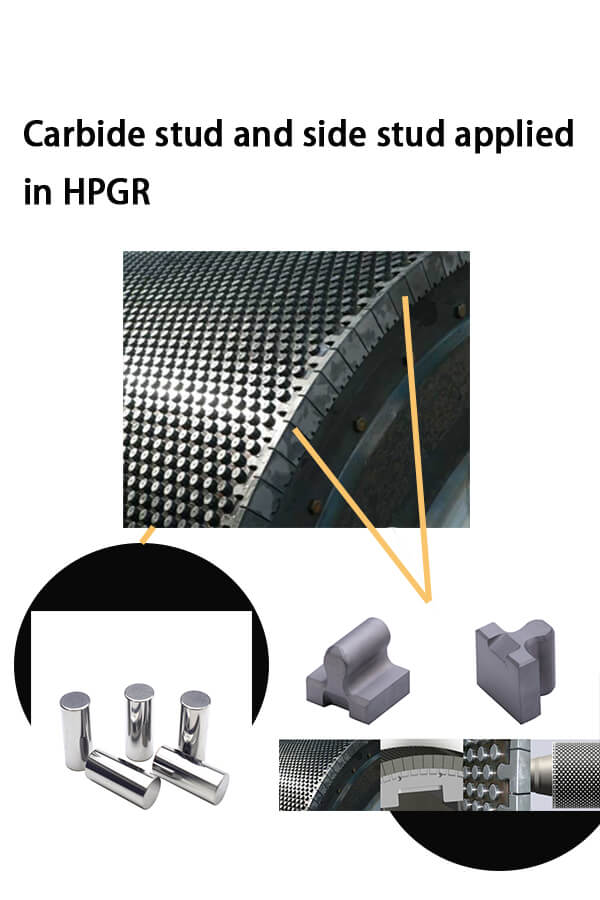

Pali mitundu itatu yayikulu ya zigawo zikuluzikulu za HPGR: PTA wosanjikiza pamwamba, centrifugal casting composite roller surface, ndi stud roller surface. Choyipa cha mitundu iwiri yoyambirira ndikuti chodzigudubuza chidzakhudzidwa kwambiri chifukwa cholumikizana mwachindunji ndi wodzigudubuza ndi zinthu zomwe zimagwiritsidwa ntchito ndi mphamvu yamphamvu ya extrusion (nthawi zambiri 50-300MPa). Njere za abrasive ndi mizere zimavala, ndipo panthawi imodzimodziyo, pamwamba pa chogudubuza chidzatulutsa maenje ofinya. Maenje osonkhanitsidwawa apangitsa kuti zinthu zodzigudubuza zitope kwambiri, zomwe zimakhudza kwambiri magwiridwe antchito a zida.

Pamwamba pa thupi la pansi amapangidwa ndi chitsulo champhamvu cha alloy, chomwe chimakhala ndi kuuma kwakukulu pambuyo pozimitsa ndi kutentha. Chosanjikiza chosamva kuvala chimapangidwa ndi tungsten-cobalt hard alloy studs ndikuyika pathupi. Nthawi zambiri, mpaka HRC67 kapena kupitilira apo, kuuma kwake ndikwapamwamba kwambiri kuposa pamwamba pa PTA wosanjikiza komanso pamwamba pa centrifugal kuponyera kompositi. Matrix a stud wodzigudubuza pamwamba akhoza kutetezedwa ndi akalowa zinthu zopangidwa. Tungsten carbide studs roller imakhala ndi moyo wautumiki wotalika kuwirikiza ka 6 kuposa momwe zimakhalira pamwamba, zomwe zimatha kupulumutsa mphamvu, kuteteza chilengedwe, kukulitsa magwiridwe antchito, komanso mtengo wotsika.

Ukadaulo wopanga mawonekedwe a carbide studs a HPGR :

1. Hemispherical kuteteza ma studs kuti asawonongeke ndi kupsinjika maganizo.

2. Mphepete zozungulira zimateteza ma studs kuti asawonongeke panthawi yopanga, kuyendetsa, kuika, ndi kugwiritsa ntchito.

3. HIP sintering kuonetsetsa kuti compactness wabwino ndi kulimba mkulu kwa mankhwala.

4. Ukadaulo wapadera wothetsera kupsinjika kwapamtunda pambuyo pogaya pamwamba ndikuwonjezera kuuma kwapamwamba.

5. Mafuta amagwiritsidwa ntchito pamwamba pa mankhwala kuti apewe oxidization.

ZZBETTER za carbide studs za HPGR

-100% zida za namwali, katundu wokhazikika wamankhwala, moyo wautali wogwira ntchito.

- Kuuma kwakukulu, kulimba kwabwino, kukana kuvala bwino.

- Makulidwe osiyanasiyana ndi mitundu yonse ilipo

- Zogulitsa zitha kusinthidwa malinga ndi zomwe mukufuna

Kulongedza zida zathu za carbide za HPGR

sitepe 1, wokutidwa carbide stud mu pepala kupewa mapini carbide stud kusweka

Gawo 2, ikani zikhomo za carbide mu bokosi lamkati laling'ono la katoni

Gawo 3, ikani bokosi lamkati mu katoni yakunja ndikudzaza katoni ndi pulasitiki ya thovu

Gawo 4, kukulunga katoni ndi ma CD tepi

Tikukulimbikitsani kuti mugwiritse ntchito zida zathu za carbide pama roller opukutira kwambiri, popeza tili ndi chidziwitso chochuluka ndipo tikusintha ndikukulitsa njira.