Market Prospect Analysis of Tungsten Carbide Bearings 02

Market Prospect Analysis of Tungsten Carbide Bearings 02

Key Growth Drivers

Key Growth Drivers

Booming Mining and Oil & Gas Exploration: As global demand for minerals (lithium for EV batteries, copper for renewable energy) and energy resources rises, mining companies are investing in high-capacity equipment—driving demand for durable bearings. For example, the International Energy Agency (IEA) predicts lithium demand will grow 40x by 2040, pushing lithium mines to adopt wear-resistant components like tungsten carbide bearings. In oil & gas, deepwater drilling (which requires extreme-pressure bearings) is expanding—offshore oil production is expected to increase by 25% by 2030, further boosting carbide bearing sales.

Rise of Renewable Energy: Wind power, in particular, is a major growth engine. The Global Wind Energy Council (GWEC) targets 2,000 GW of global wind capacity by 2030—each wind turbine requires 3-5 main shaft bearings, and the shift from steel to tungsten carbide (to reduce maintenance) is becoming a standard practice. Solar thermal power plants, which operate at high temperatures (400°C+), also rely on carbide bearings for heat exchangers, adding another demand stream.

Industrial Automation and Precision Manufacturing: The growth of smart factories and robotics (e.g., automated assembly lines, precision CNC machines) demands bearings with low friction and high accuracy. Tungsten carbide’s dimensional stability (even under high speeds) makes it ideal for these applications—automotive manufacturers, for instance, are adopting carbide bearings in robotic welding arms to reduce downtime, with the global industrial robotics market expected to reach $189.5 billion by 2030.

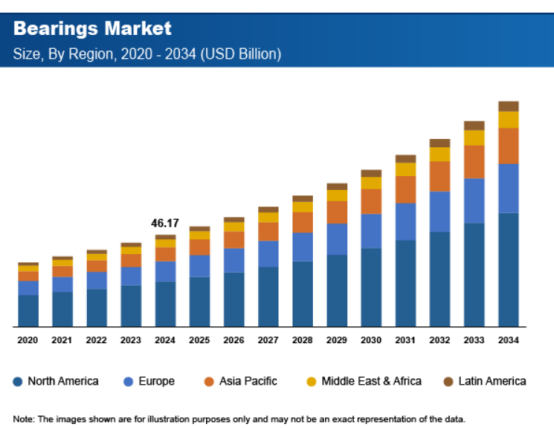

Regional Market Potential

▶▷Asia-Pacific: The largest and fastest-growing market, driven by China’s mining industry (the world’s top mineral producer) and India’s oil & gas exploration. China’s “Dual Carbon” policy (carbon peak by 2030, carbon neutrality by 2060) is also boosting wind power installations, with 500 GW of wind capacity targeted by 2030—creating massive demand for carbide bearings.

▶▷North America: Mature but high-value market, with strong demand from offshore oil (Gulf of Mexico) and wind power (U.S. Great Plains). The U.S. Infrastructure Investment and Jobs Act ($1.2 trillion) includes funding for renewable energy and mining modernization, further supporting market growth.

▶▷Europe: Leading in wind power adoption (Germany, Denmark) and precision manufacturing, with strict regulations on equipment reliability—driving premium demand for tungsten carbide bearings.

While tungsten carbide bearings offer remarkable performance, their design, installation, and maintenance require precision to maximize service life. Even with inherent durability, improper care can compromise their efficiency and shorten lifespan, so adhering to targeted maintenance practices is critical:

▶▷Lubrication Optimization: Though tungsten carbide has low friction, proper lubrication reduces residual wear and prevents micro-abrasion. Use high-performance lubricants tailored to the application environment: for high-temperature settings (e.g., oil drilling, industrial furnaces), select synthetic greases with thermal stability (operating range -40°C to 200°C or higher); for corrosive environments (e.g., marine, chemical plants), choose lubricants with anti-rust additives to reinforce the material’s natural resistance. Avoid over-lubrication, as excess grease can trap dust or debris—apply a thin, uniform layer every 3-6 months (or per manufacturer guidelines) based on usage intensity.

▶▷Regular Inspection and Cleaning: Schedule periodic checks to detect early signs of issues. For bearings in dusty or abrasive settings (e.g., mining conveyors), use compressed air (low pressure, 30-50 psi) to blow away surface debris monthly, then wipe with a lint-free cloth dampened with industrial-grade solvent (avoid harsh chemicals that may damage seals). Inspect for cracks, seal damage, or abnormal noise during operation—unusual vibrations or grinding sounds often indicate misalignment or debris buildup, which should be addressed immediately.

▶▷Proper Storage and Handling: When not in use, store tungsten carbide bearings in a dry, temperature-controlled environment (15-25°C, humidity <60%) to prevent moisture accumulation. Use anti-static packaging to avoid electrostatic damage, and avoid dropping or impact—while hard, tungsten carbide is brittle, and sharp impacts can cause micro-cracks that weaken the bearing over time. During installation, use precision tools (e.g., hydraulic presses) to ensure even force application; never hammer or pry the bearing, as this can distort the inner/outer rings.

▶▷Targeted Maintenance for Specialized Environments: For extreme applications, adjust practices accordingly. In downhole oil drilling tools, flush bearings with clean drilling fluid after each use to remove residual acidic residues; in wind turbine generators, inspect and re-lubricate bearings every 6 months (or after 500 operating hours) to account for constant wind-induced vibration.

As industries continue to push the boundaries of speed, load, and environmental resilience, tungsten carbide bearings are poised to play an even more vital role. Their ability to solve sector-specific pain points—whether mining’s abrasion, oil and gas’s pressure, marine’s corrosion, or wind power’s vibration—paired with strong market growth drivers, makes them the go-to choice for engineers seeking reliable, high-performance solutions.

In a world where machinery efficiency and durability directly impact productivity and profitability, tungsten carbide bearings stand as a testament to how innovative materials can transform industrial operations—and capture significant market value in the process.