- Mechanical processing is one of the most basic, extensive and important processes in the wood industry, which directly affects production efficiency, processing cost and energy consumption.

- When the use of machine tools is allowed, the productivity of the tool depends mainly on the cutting properties that the material itself can perform. Woodworking tools are required to maintain cutting

- Therefore, the materials for woodworking tools must have the necessary hardness and wear resistance, sufficient strength and toughness, and some degree of workmanship (e.g. welding, heat treatment, cu

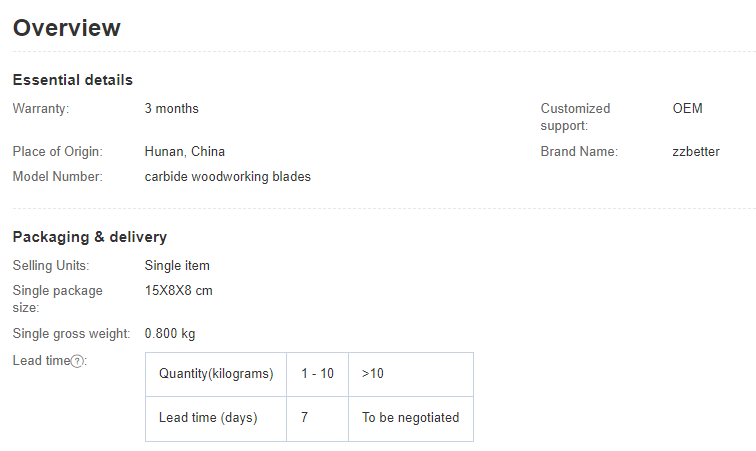

description

Carbide woodworking cutting blades

Mechanical processing is one of the most basic, extensive and important processes in the wood industry, which directly affects production efficiency, processing cost and energy consumption.When the use of machine tools is allowed, the productivity of the tool depends mainly on the cutting properties that the material itself can perform. Woodworking tools are required to maintain cutting tool sharpness over long periods of time under high speed and high impact conditions. Therefore, the materials for woodworking tools must have the necessary hardness and wear resistance, sufficient strength and toughness, and some degree of workmanship (e.g. welding, heat treatment, cutting and grinding).

Carbide woodworking cutting blades features:

- High hardness, good wear resistance - High elastic modulus - High compressive strength - Good chemical stability (acid and alkali resistance, high temperature oxidation resistance) - Low impact toughness - Low expansion coefficient, thermal conductivity and electrical conductivity similar to iron and its alloys

The advantages of Carbide woodworking cutting blades:

1. They move blades with their sharp teeth. 2. Increased efficiency and productivity due to faster cutting and shaping of wood. 3. Due to the accuracy of the machine, the consistency of cutting and shape. 4. Lower labor costs because fewer workers are needed. 5. Can handle larger and heavier wood that may be difficult with only hands.

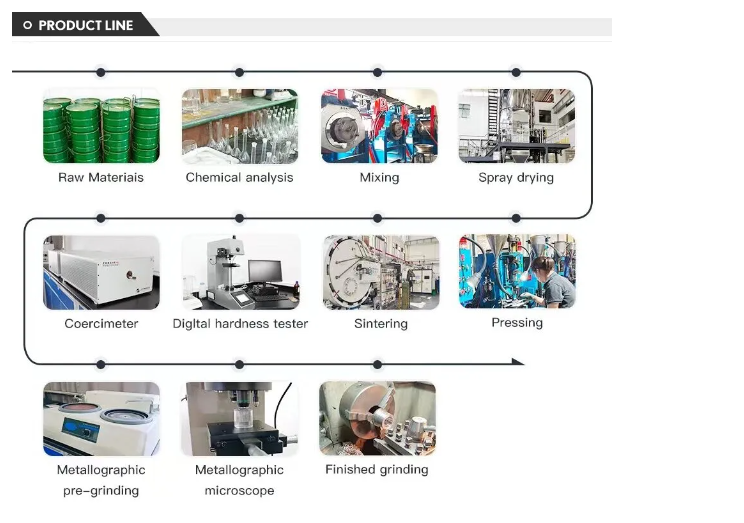

Carbide tool materials have become the main tool materials in the wood processing industry and will play an important role in the wood cutting process for a long time in the future. With the improvement of various hard alloy performance technology and coating technology, the cutting performance of hard alloy tool materials will continue to improve.

Zhuzhou Better Tungsten Carbide Co., Ltd

ADDRESS: B/V 12-305, Da Han Hui Pu Industrial Park, Zhuzhou City, China.

Phone:+86 18173392980

Tel:0086-731-28705418

Fax:0086-731-28510897

Email:zzbt@zzbetter.com

Whatsapp/Wechat:+86 181 7339 2980