Tungsten Carbide Cold Heading Dies

Tungsten Carbide Cold Heading Dies

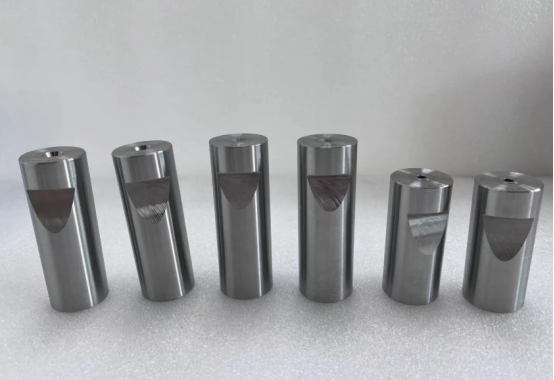

Behind the scenes of countless screws, bolts, rivets, and other fasteners being produced at rates of several pieces per second stands an indispensable "hardcore hero" – the Tungsten Carbide Cold Heading Die. Though inconspicuous, it is the core tool enabling high-efficiency, high-precision cold forming processes. This article delves into the exceptional features and wide-ranging applications of tungsten carbide cold heading dies.

I. Features of Tungsten Carbide Cold Heading Dies

The performance advantages of tungsten carbide cold heading dies are rooted in their unique material: tungsten-cobalt (WC-Co) carbide. This composite material, made from high-hardness tungsten carbide grains and a metallic cobalt binder via powder metallurgy, grants the dies three core characteristics:

1. Extreme Hardness and Wear Resistance: The hardness of tungsten carbide far exceeds that of traditional tool steel. This allows it to extremely effectively resist the severe friction and wear generated during the high-speed extrusion and upsetting of metal wire. This is the fundamental reason its service life can be tens or even hundreds of times longer than that of steel dies, drastically reducing downtime for die changes and ensuring production continuity and cost-effectiveness.

2. Outstanding Compressive Strength: Cold heading forms metal blanks at room temperature by applying enormous pressure. Tungsten carbide possesses very high compressive strength (up to 6000 MPA or more), sufficient to withstand repeated, impactful high-pressure loads without deforming compressively or cracking. This guarantees long-term stability and precision of product dimensions.

3. Good Toughness Assurance: By adjusting the cobalt content ratio, the optimal balance between hardness and toughness can be achieved. Appropriate toughness gives the die a certain level of impact and fracture resistance when facing inevitable off-center loads or material defects, preventing sudden brittle fractures and significantly enhancing operational reliability.

Furthermore, tungsten carbide offers advantages such as corrosion resistance and a low coefficient of friction, further improving its overall performance and making it the unequivocal choice for high-volume, high-quality cold heading production.

II. Core Application Areas of Tungsten Carbide Cold Heading Dies

Based on these characteristics, the applications of tungsten carbide cold heading dies cover almost all modern industrial sectors with large-scale demand for standard and special parts:

▶General Fastener Manufacturing: This is its most traditional and largest application area. From common screws, bolts, and nuts to various specifications of hex socket head screws and self-tapping screws, the mass production of nearly all metal fasteners relies on tungsten carbide cold heading dies. It ensures the dimensional uniformity and production efficiency of billions of fasteners globally.

▶Automotive Industry: A modern car consists of tens of thousands of parts. A large number of critical components, such as special engine bolts, transmission gear shafts, various pins, and valve tappets, are manufactured using cold heading. Tungsten carbide dies are key to producing these high-strength, high-precision, high-consistency parts, directly impacting the reliability and safety of automobiles.

▶Electronics and Appliance Manufacturing: Products like mobile phones, computers, and household appliances are filled with various tiny, precision hardware components internally, such as phone screws, connector pins, and heat sink brackets. Tungsten carbide cold heading dies can form these micro, special-shaped parts with high precision and smoothness, meeting the electronics industry's stringent demands for miniaturization and precision.

▶Aerospace and High-End Equipment Manufacturing: This sector has the most extreme performance requirements for fasteners and structural components. The forming of high-strength, high-temperature-resistant titanium alloy or special alloy fasteners used in critical areas like aircraft engines and airframes also relies on the superior performance of tungsten carbide dies.

In summary, the tungsten carbide cold heading die is an "unseen cornerstone" of modern high-end manufacturing. With its unparalleled hardness, strength, and wear resistance, it silently supports the vast production system ranging from everyday goods to high-end equipment, making it an indispensable key tool in the industrial model of large-scale, high-efficiency, and high-quality production.

Ready to Elevate Your Production Line?

Unlock unparalleled efficiency, extended tool life, and superior component quality with ZZBETTER's precision-engineered tungsten carbide cold heading dies. Our experts are ready to provide tailored solutions for your specific application challenges.