Nzira yekucheka Tungsten Carbide Rod?

Nzira yekucheka Tungsten carbide rod?

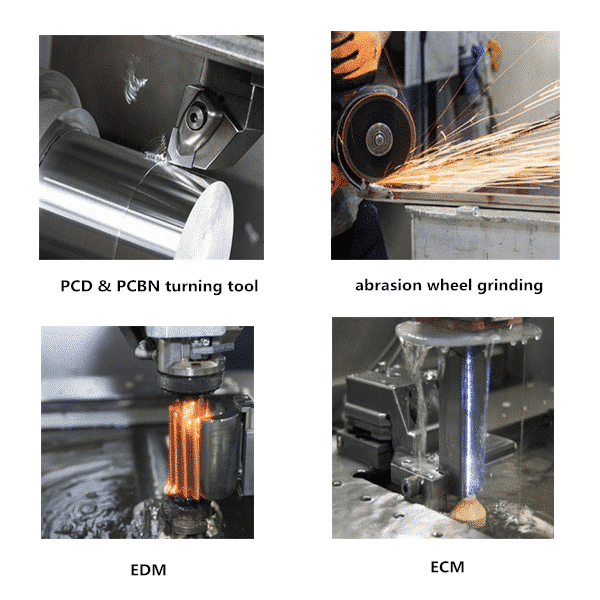

Isu tinoziva kuti kuoma kwechishandiso pachacho kunofanira kunge kwakakwira kupfuura kuomarara kwechikamu chebasa chinogadzirwa. Iyo Rockwell kuoma kweiyo simende carbide kunowanzo kutenderedza HRA78 kusvika HRA90. Kana uchida kukora kana kucheka tungsten carbide rods zvine pundutso, nzira ina dzinotevera dzinogona kushanda, dzinoti abrasion wheel grinding, machining by super hard material, electrolytic machining(ECM), uye electric discharge machining(EDM).

1. Cheka carbide rod usina chinhu nekukuya nemavhiri

Kubva zvino zvichienda mberi, zvinhu zvinogona kugadzira carbide blanks zvinonyanya kureva poly-crystalline cubic boron nitride (PCBN) uye poly-crystalline diamond (PCD).

Zvinhu zvikuru zvekukuya mavhiri zvakasvibirira silicon carbide nedhaimani. Sezvo kukuya kwesilicon carbide kuchizoburitsa kushushikana kwemafuta kunodarika simba reiyo simende carbide, kutsemuka kwepasi kunoitika kwakawanda, izvo zvinoita kuti silicon carbide isave sarudzo yakanaka yekugadzira nzvimbo inogona kuvimbiswa.

Kunyangwe iyo PCD yekukuya vhiri inokwanisa kupedzisa mabasa ese kubva pakukasira kusvika pakupedzisa pacarbide blanks, kuitira kuderedza kurasikirwa kwegumbo rekukuya, carbide blanks ichafanogadziriswa nemagetsi machining nzira, wozoita semi-kupedza uye zvakanaka- kupedzisa nekugaya vhiri pakupedzisira.

2. Cheka carbide bar nekugaya nekutenderedza

Zvishandiso zveCBN nePCBN, zvakagadzirirwa senzira yekucheka simbi nhema nekuomarara, senge simbi yakaoma uye simbi yakakandwa (simbi). Boron nitrite inokwanisa kumira kusimba kwekushisa kwepamusoro (pamusoro pe1000 madhigirii) uye inobata kuomarara pa8000HV. Iyi pfuma inoita kuti ive yakaenzana nekugadziriswa kwecarbide blanks, kunyanya kune izvo zvimiro zvikamu zvinoumbwa necarbide core uye simbi casing pasi pekupindira kwekupindirana.

Zvakadaro, kana kuomarara kwezvikamu zvecarbide zvine simende kwakakwira kupfuura HRA90, kunze kweligi reboron nitrite kucheka, hapachada kusimbirira paPCBN neCBN zvishandiso.

Isu hatigone kurasikirwa nekuona kusakosha kwePCD inoisa, kusakwanisa kwayo kuwana mipendero yakanyanya kupinza uye kusagadzikana kugadzirwa nema chipbreakers. Naizvozvo, PCD inogona kungoshandiswa kucheka kwakanaka kweasina-ferrous simbi uye asiri-simbi, asi haigone kuwana yekupedzisira-chaiyo girazi-kucheka kwecarbide blanks, zvirinani zvisati zvaitika.

3. Electrolytic Machining (ECM)

Electrolytic processing ndiko kugadzirisa kwezvikamu nemusimboti wekuti carbide inogona kunyungudika mu electrolyte (NaOH). Inovimbisa kuti pamusoro peiyo carbide workpiece haidziye. Uye iyo poindi ndeyekuti ECM yekumhanyisa kugadzirisa uye kunaka kwekugadzirisa zvakasununguka pane zvemuviri zvimiro zvezvinhu zvinogadziriswa.

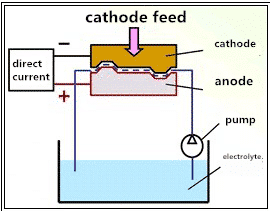

4. Electric dicharge machining (EDM)

Nheyo yeEDM yakavakirwa pane yemagetsi corrosion phenomenon pakati pechishandiso uye workpiece (yakanaka uye isina kunaka electrode) panguva yekuyerera kwe pulse spark discharge kubvisa zvakawandisa carbide zvikamu kuti zvizadzise zvakafanotemerwa zvekugadzirisa zvinodiwa pakukura, chimiro uye pamusoro pemhando yeworkpiece. . Chete mhangura-tungsten maelectrodes uye copper-silver electrodes anogona kugadzira carbide blanks.

Muchidimbu, EDM haishandisi simba remagetsi, haibvi pakucheka masimba kuti abvise simbi, asi anoshandisa zvakananga simba remagetsi uye kupisa kubvisa chikamu checarbide.