Zvimiro zveCarbide Insets uye Yambiro yeKushandisa Cemented Carbide Insets

Zvimiro zveCarbide Insets uye Yambiro yeKushandisa Cemented Carbide Insets

Carbide inoiswa inoshandiswa nekumhanya kwakanyanya kunogonesa kukurumidza machining, pakupedzisira zvichikonzera kupedzisa kuri nani. Carbide inoisa zviturusi zvinoshandiswa kunyatso simbi dzemuchina, zvinosanganisira simbi, kabhoni, simbi yakakandwa, alloys akakwira-tembiricha, uye mamwe masimbi asina ferrous. Izvi zvinotsiviwa uye zvinouya mumhando dzakasiyana, mamaredhi, uye saizi.

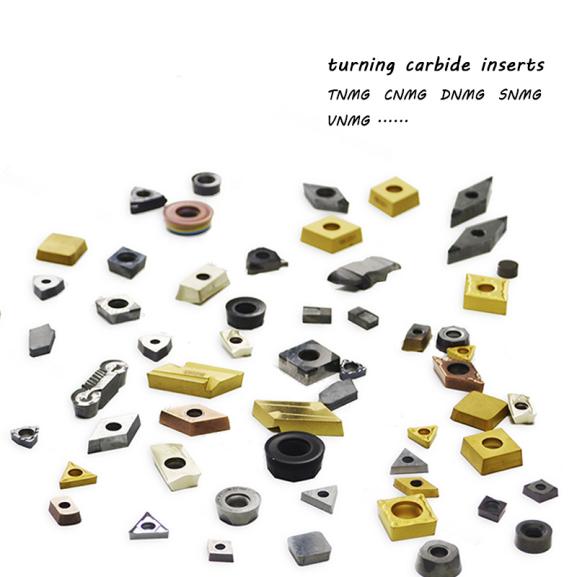

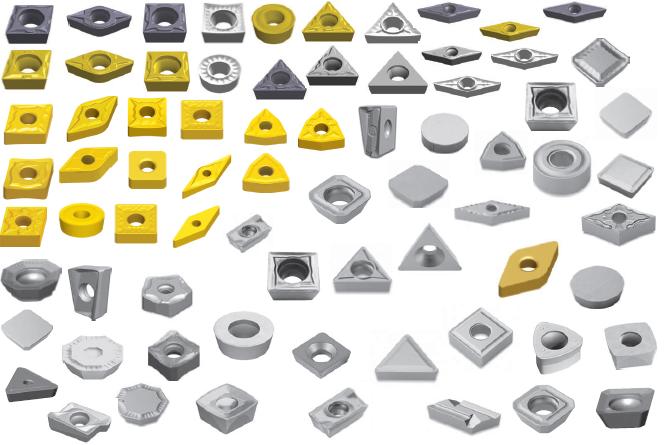

Kune akasiyana mashandiro ekucheka, carbide inoiswa inogadzirwa mumhando dzakasiyana siyana dzejometri dzakagadzirirwa kune yega application.

Round or circular inserts anoshandiswa kumabhatani zvigayo kana kuti radius groove kutenderera nekuparadzana. Mabhatani ezvigayo, anonziwo makopi ekucheka, anoshandisa denderedzwa anoisa ane akakosha eradius mupendero anobvumira kukwidziridzwa kwekudya uye kudzika kwekucheka pasimba rakaderera. Radius groove kutendeuka ndiyo maitiro ekucheka radial grooves kuita chikamu chakatenderera. Kupatsanura inzira yekucheka zvachose kuburikidza nechikamu.

Triangular, square, rectangular, diamond, rhomboid, pentagon, uye octagon maumbirwo ane macheto akawanda ekucheka uye anobvumira kupinza kuti kutenderedzwe kumucheto mutsva, usingashandiswe kana mupendero wapfekwa. Aya anoisa anoshandiswa kutenderedza, kufinha, kuchera, uye grooving application. Kuwedzera hupenyu hwekupinza, mipendero yakasakara inogona kushandiswa kuita roughing maapplication isati yatenderedzwa kune imwe kumucheto kwekupedzisa machining.

Yakasiyana matipi geometries inotsanangurazve kuisa chimiro uye marudzi. Insert inogadzirwa neakasiyana matipi angles, anosanganisira 35, 50, 55, 60, 75, 80, 85, 90, 108, 120 uye 135 madhigirii.

Yambiro yekushandiswa kwecemented carbide insert

1. Teerera kucheki yezwi: paunenge uchiisa, tapota nyatsotarisisa nechigunwe chekurudyi pane chekuisa uye chigadziro chiri kuuya, wobva wadzvanya kuisa nenyundo yehuni, ipa nzeve kuti uteerere inzwi rekuisa. Ruzha rwemadhaka runoratidza kuti kuiswa kunowanzo kukanganiswa nekunze kwesimba, kudhumhana, uye kukuvara. Uye kuiswa kunofanira kurambidzwa pakarepo.

2. Kugadzirira kwe tungsten carbide kuisa kuisa: kusati kwaisa kuiswa, tapota nyatsochenesa guruva, machipisi, uye zvimwe zvakasiyana-siyana pane inokwira pamusoro peiyo rotary inotakura yemuchina wekucheka pachine nguva kuti uchengetedze kutakura kukwira kumusoro uye muchina wekucheka wakachena. .

3. Isa iyo inopinza zvakanyatsonaka uye zvakanaka pamusoro pekukwira pamusoro pekutakura uye shandura kubereka kwegumbo rekucheka nemaoko kuti iite kuti ienderane nechepakati pekuisa.

4. Mushure mekuiswa kwecarbide kuiswa, hapanofanira kuva nekusununguka kana kukanganisa.

5. Kudzivirirwa kwekuchengetedza: Mushure mokunge cemented carbide cutting tool yakasimwa, chivharo chekuchengetedza uye zvimwe zvidziviriro zvekudzivirira zvemuchina wekucheka zvinofanira kuiswa panzvimbo isati yatanga muchina wekucheka.

6. Muchina wekuedza: mushure mokunge cemented carbide tool yakaiswa, mhanya usina chinhu kwemaminitsi mashanu, uye nyatsocherechedza uye teerera mamiriro ekumhanya emakumbo ekucheka kwetsoka. Hapana kusunungura kuri pachena, kuzunguzika, uye zvimwe zvisingaite zvinonzwika zvinotenderwa. Kana paine chimwe chinhu chisina kujairika chikaitika, ndapota mira nekukurumidza uye bvunza vashandi vehunyanzvi kuti vatarise zvakakonzera kukanganisa, uye kusimbisa kuti kukanganisa kwabviswa usati washandiswa.

Carbide inoisa nzira yekuchengetera: inorambidzwa zvachose kunyora kana kumaka pane inoiswa nekushandisa penzura kana imwe nzira yekukwenya kudzivirira mutumbi wekuisa kukuvara. Iyo yakasimwa carbide yekucheka chishandiso yemuchina wekucheka tsoka yakanyanya kupinza asi ine brittle. Kuti udzivise kukuvadzwa kwekuisa kana kukanganisa kwetsaona kwekuisa, vachengetedze kure nemuviri wemunhu kana zvimwe zvinhu zvakaoma zvesimbi. Idzo dzinofanira kushandiswa dzinofanira kuchengetwa zvakanaka uye kuchengetwa nevashandi vakazvipira, uye hadzifanirwe kushandiswa zvisina basa, kana zvakaiswa zvakakuvadzwa uye zvichikonzera tsaona.