Chii chinonzi Tungsten Carbide Studs YeHPGR?

Chii chinonzi Tungsten Carbide Studs YeHPGR?

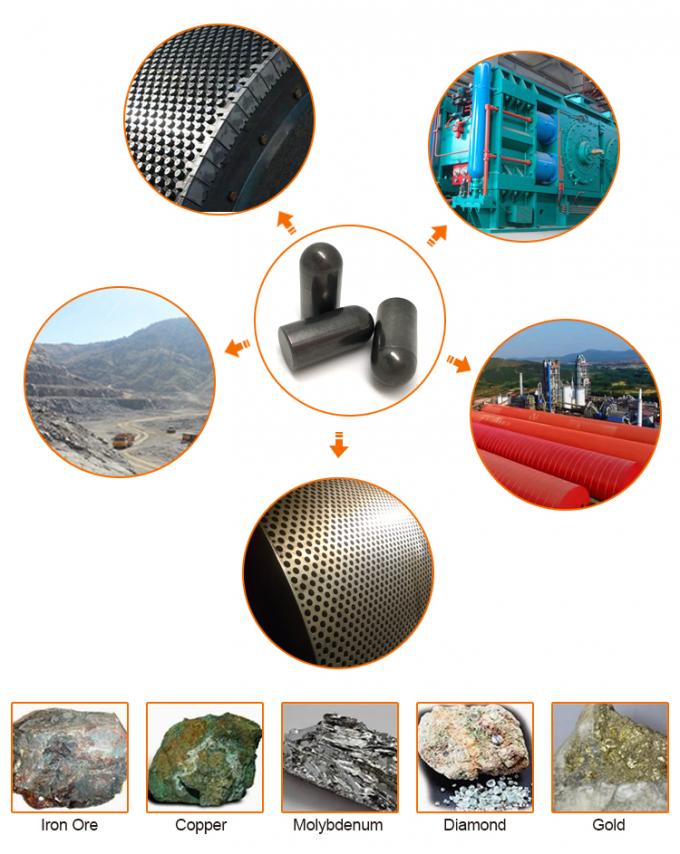

Tungsten carbide studs inonziwo cemented carbide studs, carbide mabhatani, uye carbide matipi, ayo anoshandiswa zvakanyanya kukwirisa-kukuya roller. Carbide studs anoshandiswa kune yakakwirira-kumanikidza kugaya roller yekupwanya simende mbishi zvinhu, clinker, iron ore, mhangura, diamondi, uye quartz. Hupenyu hwese hunogona kusvika maawa 8000-30000 zvichienderana nemagiredhi akasiyana nemashandisirwo akasiyana.

Cemented carbide studs sechikamu chepakati che vertical impact crusher (sandstone equipment) inoshandiswa zvakanyanya mumigodhi, jecha nematombo, simende, metallurgy, hydropower engineering, uye mamwe maindasitiri, ayo anokumbira kuti zvigadzirwa zvimire nekumhanya-mhanya uye kusimba kwekupfeka. , uye kushandisa simende carbide isarudzo yakanaka. High-Pressure Grinding Roller isimba-rinoshanda rinopwanya michina yematekinoroji matsva. Kuita kwepamusoro kweiyo carbide stud kunowedzera hupenyu hweHigh-Pressure Grinding Roller. ZZBETTER inopa mhando ye carbide studs nekunaka kupfeka kusagadzikana uye yakakwirira yekumanikidza simba, iyo inogona kugutsa zvinodiwa nemamiriro akasiyana.

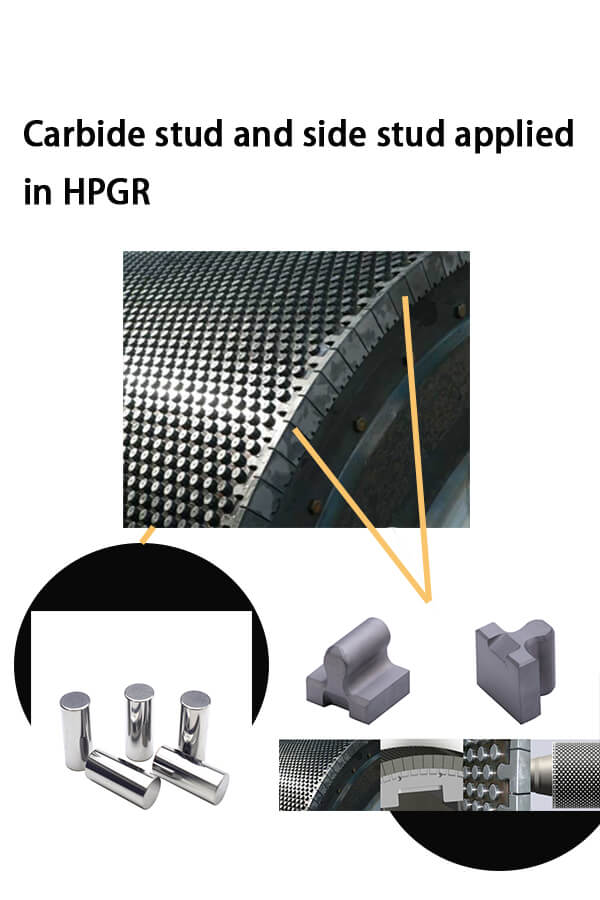

Kune marudzi matatu makuru emhando dzepakati peHPGR: PTA layer roller surface, centrifugal casting composite roller surface, uye stud roller surface. Izvo zvisingabatsiri zvemhando mbiri dzekutanga ndezvekuti iyo roller surface ichave yakatarisana nekukanganiswa kwakanyanya nekuda kwekusangana kwakananga kwerori nezvinhu zviri pasi pekuita kwesimba rakasimba reextrusion (kazhinji 50-300MPa). Iyo abrasive zviyo uye furrows inopfeka, uye panguva imwechete, iyo roller surface inoburitsa makomba ekusvina. Aya makomba akaunganidzwa anokonzeresa kupera simba kweiyo roller pamusoro zvinhu, izvo zvinokanganisa zvakanyanya kushanda kwakajairika kwemidziyo.

Iyo stud roller pamusoro peiyo base body inogadzirwa ne-high-simba alloy simbi, iyo ine yakanyanya kuoma mushure mekudzima uye kupisa. Iyo yekupfeka-inodzivirira layer inogadzirwa ne tungsten-cobalt yakaoma alloy studs uye yakanamirwa pamuviri. Kazhinji, kusvika kuHRC67 kana kupfuura, kuoma kwacho kwakakwirira kudarika PTA layer roller surface uye centrifugal casting composite roll surface. Iyo matrix ye stud roller surface inogona kuchengetedzwa nemucheka wezvinhu wakagadzirwa. Tungsten carbide studs roller ine hupenyu hwesevhisi kanopfuura katanhatu kupfuura iyo yepamusoro peiyo roller surface, inogona kuchengetedza simba, kuchengetedza nharaunda, kuwedzera kushanda zvakanaka, uye mutengo wakaderera.

Kugadzira tekinoroji maficha ecarbide studs yeHPGR:

1. Hemispherical kudzivirira ma studs kubva pakuparadzwa nekunetseka kwekunetseka.

2. Mipendero yakatenderedza inodzivirira ma studs kubva pakukuvadzwa panguva yekugadzira, yekufambisa, kuiswa, uye kushandiswa.

3. HIP sintering inova nechokwadi chekubatana kwakanaka uye kusimba kwepamusoro kune zvigadzirwa.

4. Yakakosha tekinoroji yekubvisa kushushikana kwepamusoro mushure mekukuya kwepamusoro uye kuwedzera kuoma kwepamusoro.

5. Girasi rinoshandiswa pamusoro pezvigadzirwa kudzivirira oxidization.

ZZBETTER's carbide studs yeHPGR

-100% mhandara mbishi, yakagadzikana makemikari zvinhu, hupenyu hurefu hwekushanda.

-Kuomarara kwepamusoro, kusimba kwakanaka, kupfeka kwakanakisa kuramba.

- Yakasiyana saizi uye azere marudzi aripo

- Zvigadzirwa zvinogona kugadzirwa pane zvinodiwa

Kurongedza zvedu carbide studs zveHPGR

nhanho yekutanga, yakaputirwa carbide stud mubepa kudzivirira carbide stud pini kuputswa

nhanho yechipiri, isa carbide stud pini mukati memukati diki bhokisi bhokisi

nhanho yechitatu, isa bhokisi remukati mubhokisi rekunze uye uzadze katoni nepurasitiki ine furo

nhanho 4, putira katoni nematepi ekurongedza

Isu tinokukurudzira kuti ushandise ma carbide studs kune akanyanya-kumanikidza kugaya rollers, sezvo isu tine ruzivo rwakawanda uye tiri kugara tichigadzirisa uye kugadzira maitiro.