Nei Zvigadzirwa zveTungsten Carbide Zvichidonha Mushure meSintering

Sei Tungsten Carbide Zvigadzirwa Zvichidonha Mushure meSintering?

Tungsten carbide ndechimwe chezvinhu zvakakurumbira zvekushandisa muindasitiri yemazuva ano. Mufekitori, tinogara tichishandisa poda metallurgy kugadzira tungsten carbide zvigadzirwa. Mukuita sintering, unogona kuona kuti tungsten carbide zvigadzirwa zvakadzikira. Saka chii chakaitika kune tungsten carbide zvigadzirwa, uye nei tungsten carbide zvigadzirwa zvakadzikira mushure mekupisa? Muchikamu chino, tichaongorora chikonzero.

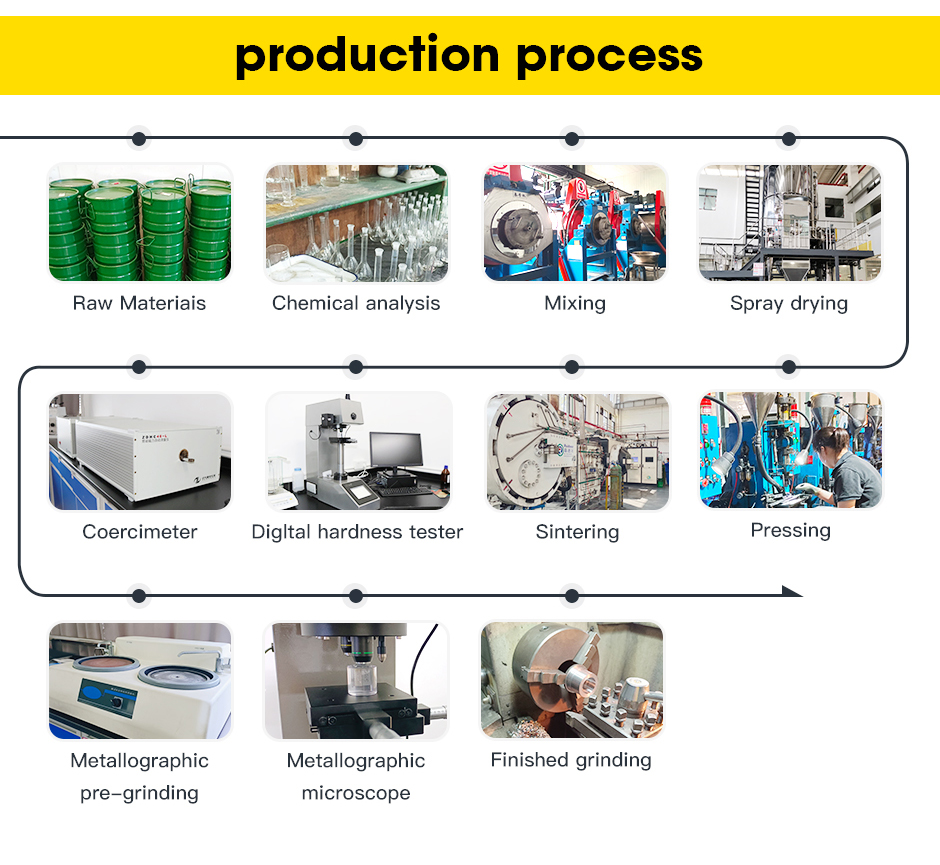

Kugadzira tungsten carbide zvigadzirwa

1. Kusarudza uye kutenga 100% mbishi zvinhu, tungsten carbide;

2. Kusanganisa tungsten carbide powder necobalt powder;

3. Kukuya hupfu hwakasanganiswa mumushini wekusanganisa bhora neimwe mvura yakaita semvura uye ethanol;

4. Pfaya uchiomesa hupfu hwakanyorova;

5. Kubatanidza hupfu muzvimiro zvakasiyana uye hukuru maererano nezvinodiwa nevatengi. Nzira dzakakodzera dzekutsikirira dzinosarudzwa nemhando uye saizi ye tungsten carbide zvigadzirwa;

6. Kupisa muvira romoto;

7. Kuongorora kwehutano hwekupedzisira.

Matanho e sintering tungsten carbide zvigadzirwa

1. Kubviswa kweiyo molding agent uye pre-burning stage;

Muchikamu chino, mushandi anofanira kudzora tembiricha kuti iwedzere zvishoma nezvishoma. Sezvo tembiricha ikawedzera zvishoma nezvishoma, hunyoro, gasi, uye yakasara solvent mu compacted tungsten carbide inobuda, saka nhanho iyi ndeyekubvisa iyo yekuumba uye zvimwe zvinhu zvakasara uye pre-kutsva. Iyi nhanho inoitika pasi pe800 ℃

2. Solid-phase sintering stage;

Sezvo tembiricha inowedzera uye ichipfuura 800 ℃, inotendeukira kune yechipiri nhanho. Danho iri rinoitika mvura isati yavapo muhurongwa uhu.Muchikamu chino, kuyerera kwepurasitiki kunowedzera, uye muviri wakasvibiswa unoderera zvakanyanya.Tungsten carbide shrinking inogona kucherechedzwa zvakakomba, kunyanya pamusoro pe1150 ℃.

Cr. Sandvik

3. Liquid-phase sintering stage;

Munguva yechitatu, tembiricha ichawedzera kusvika kune sintering tembiricha, tembiricha yepamusoro panguva yekupisa. Iyo shrinkage inopedzwa nekukurumidza kana chikamu chemvura chikaonekwa pane tungsten carbide uye porosity ye tungsten carbide inoderera.

4. Kutonhora danho.

Iyo carbide yakasimwa mushure mekupisa inogona kubviswa kubva muchoto chekupisa uye kunyoroveswa kusvika kukamuri tembiricha. Mamwe mafekitari achashandisa kupisa kwemarara muchoto chekupisa kuitira kushandiswa kutsva kwekupisa. Panguva ino, sezvo kutonhora kunodonha, iyo yekupedzisira microstructure yealloy inoumbwa.

Kana iwe uchifarira tungsten carbide zvigadzirwa uye uchida rumwe ruzivo uye ruzivo, unogona KUBATA NESU nerunhare kana tsamba kuruboshwe, kana kuti TUMUMA MAIL pazasi peji.