Sida Loo Doorto Alaabta Sibidhka Ulaha Carbide

Sida Loo Doorto Alaabta Sibidhka Ulaha Carbide

Markaad akhrido 8-da talo soo jeedin, waxaad ogaan doontaa sida loo doorto alaab-qeybiyaha ulaha carbide

Ulaha carbide sibidhka ah ayaa sababa waxqabadkooda jireed ee weyn, ayaa si weyn loogu isticmaalaa samaynta qalabka wax lagu gooyo, inta badan halkii laga heli lahaa birta xawaaraha sare leh. Xataa haddii ulaha tungsten carbide qiimihiisu ka sarreeyo ulo HSS, dad badan ayaa la mid ah ulaha carbide tungsten. Nolosha shaqada ee dheer ee ulaha adag ee birta ayaa kaa caawin kara kordhinta waxtarka.

Waxaa jira boqolaal soosaarayaasha ulaha carbide tungsten adduunka oo dhan. Sidee loo doortaa alaab-qeybiyaha tungsten carbide rods?

1. Wax cayriin

Waa inaad doorataa ulaha carbide tungsten oo laga sameeyay 100% walxo bikrad ah. Soo-saaruhu waa inuu ku sameeyaa tijaabinta kiimikada fiidmeer kasta oo alaabta ceeriin ah.

2. Darajooyinka

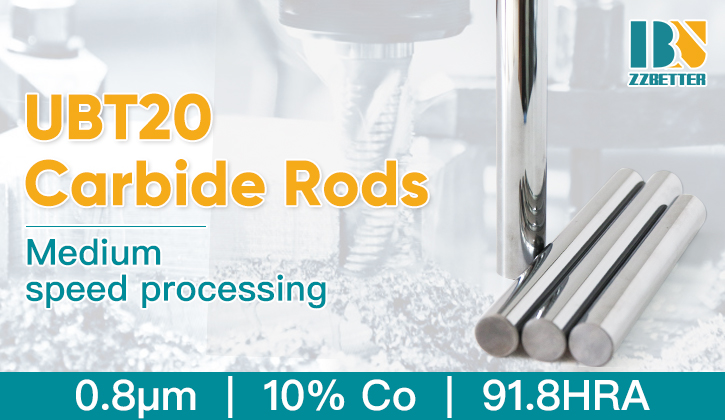

Ulaha Carbide ee samaynta qalabka goynta si loogu farsameeyo biraha kala duwan ee xaaladaha mashiinada kala duwan. Alaab-qeybiyeyaasha ulaha carbide waxay u baahan yihiin inay cilmi-baaris ku sameeyaan oo ay horumariyaan darajooyinka ulaha carbide ee kala duwan codsiyada kala duwan. Waxay hubin kartaa inaad dooran karto buundada kugu habboon codsigaaga.

3. Waayo-aragnimada soo saarida ulaha carbide tungsten

Warshadaha qaarkood waxay leeyihiin khibrad qani ah oo ku saabsan soo saarista alaabada carbide tungsten. Waxay ogaadeen inuu jiro suuq weyn oo loogu talagalay ulaha carbide, waxay bilaabaan inay soo saaraan ulaha carbide sibidhka. Xitaa haddii geeddi-socodka ulaha carbide tungsten uu la mid yahay alaabada kale ee carbide. Si kastaba ha ahaatee, weli waxaa jira kala duwanaansho. Tusaale ahaan, ulaha carbide ee leh usha qaboojinta tooska ah ee leh 2 iyo 3 godadka, haddii aan khibrad lahayn, ma xakameyn karaan toosnaanta daloolka.

4. Khadka wax soo saarka

Inta badan soosaarayaasha carbide waxay soo saaraan ulaha carbide leh alaabada carbide ee tungsten kale ee aqoon isweydaarsiga, isla shaqaale. Haddii warshadda carbide-ka ee sibidhka ah ay leedahay khad wax soo saar madax-bannaan oo loogu talagalay ulaha carbide, way fiicnaan doontaa. Waxay hubin karaan ilaalinta tayada habraac kasta.

5. Qalabka wax soo saarka

Dalka Shiinaha waxa jirta maahmaah Shiineys ah oo odhanaysa ma samayn karo leben la’aan caws la’aan. Qalabka horumarsan waa mid aad muhiim u ah, xitaa haddii injineerada iyo shaqaaluhu ay leeyihiin khibrad qani ah, iyada oo aan lahayn qalab horumarsan, ma soo saari karaan tayada sare ee tungsten carbide ulaha.

Qalabka ugu muhiimsan waa munaaradda buufinta budada ah, mashiinka riixaya ee isostatic ama mashiinka extrusion, mishiinka sinta

6. Nidaamka ilaalinta tayada

Wax dhib ah ma leh alaabta ceeriin, habka wax soo saarka, ama ulaha carbide ee la dhammeeyey, waa in uu jiraa nidaam xakamaynta tayada adag ee habka oo dhan. Gaar ahaan ulaha carbide la dhammeeyayna, ma aha oo kaliya in la hubiyo in size gabal gabal, waxqabadka jirka sida qallafsanaan, cufnaanta, anti-qaloocinta xoog, metallogram badan in la falanqeeyo.

7. Heerka shiididda

Haddii aad u baahan tahay ulaha carbide shiida h6 ama h5 dulqaadka, waxaad u baahan tahay inaad hubiso mishiinka shiida, shiida heerka farsamada. Soosaarayaasha qalabka wax lagu gooyo waxay ogyihiin sida ay muhiimka u tahay isbarbardhigga ulaha. Inkasta oo jir ahaan ulaha carbide ay wanaagsan yihiin, iyada oo aan si fiican loo barbar dhigin, qalabka wax lagu gooyo waa sahlan tahay in la xidho ama la jebiyo.

8. Waqtiga keenista

Guud ahaan, wakhtiga wax soo saarka ee ulaha carbide waxay u baahan yihiin 15-30 maalmood.

Waxaad dooran kartaa kuwa leh cabbir buuxa oo ulaha carbide ah ee kaydka ah.

Waxay kaa caawin kartaa inaad kaydsato wakhtiga sugitaanka.

In oo dhan, Waayo, carbide qalab goynta manufactories, Waxay door bidaan lahaa shuruudaha iskaashiga dheer. Doorashada ulaha carbide ma aha sida iibsashada maroes, waxay la mid tahay doorashada lammaane iskaashi. Markaa in badan diirada saar alaabta ceeriin, farsamooyinka wax soo saarka, xakamaynta tayada ayaa ka faa'iideysan doonta in ka badan diiradda qiimaha.