Noocyada Tungsten Carbide Buttons iyo Talooyin Qaar

Noocyada Tungsten Carbide Buttons iyo Talooyin Qaar

Noocyada badhamada carbide tungsten waa:

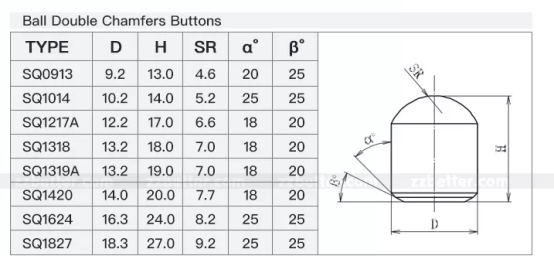

1. Badhamada wareegsan

Badhamada wareegsan ayaa loogu talagalay in lagu dejiyo dubbaha dhagaxyada, DTH, iyo koodhka rollerka ee qalabka saliidda ee qaababka dhagaxyada adag.

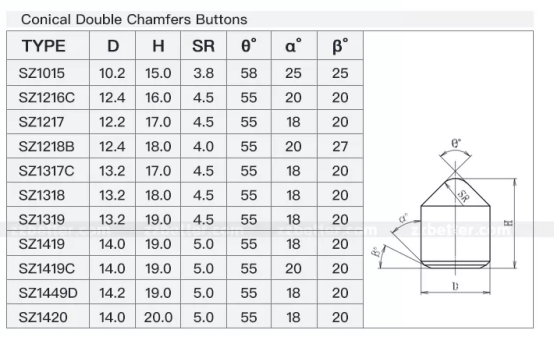

2. Badhamada conical Carbide

Badhamada tolanka ah waxaa loogu talagalay galinta biraha dubbaha qodida dhagaxa, DTH, iyo koodhka rullaluistemadka, oo ku habboon samaynta dhagaxyada adag ee dhexdhexaadka ah.

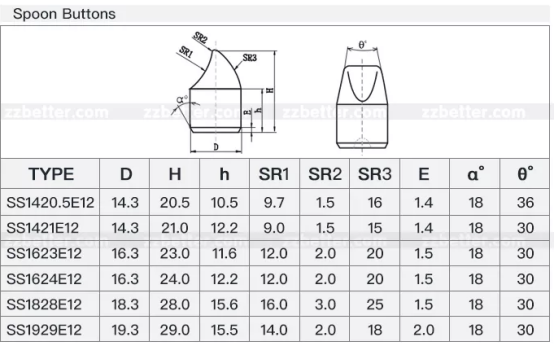

3. Badhamada xabadda

Badhamada rasaastu waa in la geliyo DTH iyo koodhka koodhka, oo ku habboon samaynta dhagaxyada adag.

Ilkaha sare ee fidsan, oo ku habboon qaniinyada koontada rullaluistuliga ah, biraha dheemanka ah, xasiliyayaasha daloolka, iwm.

4. Badhan qaaddo-qaabeeya

Badhamada qado-qaadka u samaysan ayaa loogu talagalay in la geliyo qaniinyada koodhka rollerka ee qodista xawaaraha sare ee qaababka dhagaxa jilicsan.

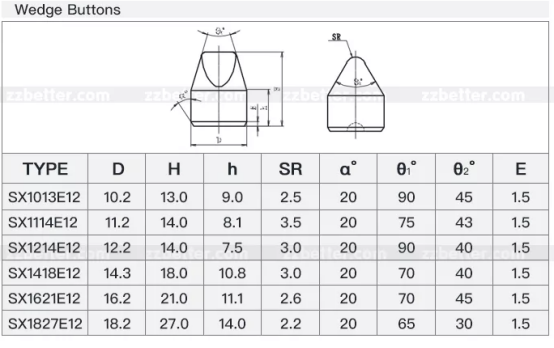

5. Badhamada jeexjeexa

Badhamada qaabaysan jeexjeexyada, oo loo isticmaalo gelinta qaababka gaarka ah ee DTH bits iyo koodhka koodhka, waxay ku habboon yihiin qaababka dhagaxyada jilicsan ee leh ROP sare iyo ilko jaban oo hooseeya.

Badhamada carbide-ka sibidhka ah ee aan kor ku soo sheegnay ee qaabab kala duwan leh ayaa leh adeegsigooda iyo sifooyinkooda shaqo. Waa maxay nooca batoonka carbide sibidhka ah waa in la isticmaalo iyadoo lagu saleynayo imtixaanka, waxaana lagu doortaa si waafaqsan xaaladda dhabta ah.

Isticmaalka macquulka ah ee badhamada carbide

Habka isticmaalka macquulka ah ee badhamada carbide sibidhka, qodobbada soo socda waa in fiiro gaar ah loo yeesho:

1. Don't treat it casually because of wear resistance. Any drill bit needs to monitor its use at any time. Once an abnormality is found, if it is repaired in time, the carbide button drill bit is no exception. We must always pay attention to whether it has a "cracking" phenomenon or peeling. When this happens, it means that the wear of the drill affects its use, and it needs to be repaired. When the rock drilling speed of the rock drill drops significantly, we should also consider that it may be due to excessive wear of the drill.

2. Waa in aan la isticmaalin xoog inta lagu jiro hawlgalka. Awoodda kicinta waa in la dhimo si loo yareeyo walbahaarka badhanka carbide. Isla mar ahaantaana, xaddi badan oo biyo ah waa in loo isticmaalo xoqidda si meesha looga saaro wasakhda ka dhalata inta lagu jiro hawlgalka wakhtiga. Sidoo kale waa in fiiro gaar ah loo yeesho isticmaalka biyaha lagu dhaqo, waa in si joogto ah loo nadiifiyo, iyo biyo shubashada waa in goor hore la bilaabo marka kaliya la shaqeynayo. Haddii kale, waxay keeni doontaa in heerkulka qalabka daloolku kor u kaco ka dibna si lama filaan ah ula kulmaan biyaha si ay u qaboojiyaan oo ay dilaan.

ZZBETTER waxay leedahay noocyo kala duwan oo ah ilkaha kubbadda sibidhka ee sibidhka, iyo cabbirro kala duwan oo badhamada macdanta carbide sibidhka ah ayaa la soo saari karaa oo la habeyn karaa.

Haddii aad xiisaynayso alaabada carbide ee tungsten oo aad rabto macluumaad iyo tafaasiil dheeraad ah, waxaad nagula soo xidhiidhi kartaa telefoon ama boostada dhanka bidix, ama US POST ku soo dir qaybta hoose ee bogga.