Mekhoa e fapaneng ea ho Tobetsa Tungsten Carbide Rods

Mekhoa e fapaneng ea ho Tobetsa Tungsten carbide rods

Tungsten carbide e tsejoa e le e 'ngoe ea lisebelisoa tse thata ka ho fetisisa, tse ka tlase ho daemane. Ho hlahisa tungsten carbide, basebetsi ba tlameha ho e hatella hore e be sebopeho se itseng. Ha ho etsoa, ho na le mekhoa e meraro ea ho hatella phofo ea tungsten carbide ho lithupa tsa tungsten carbide. Li na le melemo le ts'ebeliso ea tsona.

Mekhoa ke:

1. Die Pressing

2. Extrusion Pressing

3. Dry-bag Isostatic Pressing

1. Die Pressing

Die pressing ke ho tobetsa lithupa tsa tungsten carbide ka hlobo. Mokhoa ona ke oona o tloaelehileng ka ho fetisisa le o sebelisoang haholo. Nakong ea khatiso, basebetsi ba eketsa parafine e le ntho e ka etsang hore motho a sebetse hantle, a khutsufatse nako ea tlhahiso, 'me a boloke litšenyehelo tse eketsehileng. 'Me parafine e bonolo ho e ntša nakong ea sintering. Leha ho le joalo, lithupa tsa tungsten carbide ka mor'a ho hatella lefu li hloka ho siloa.

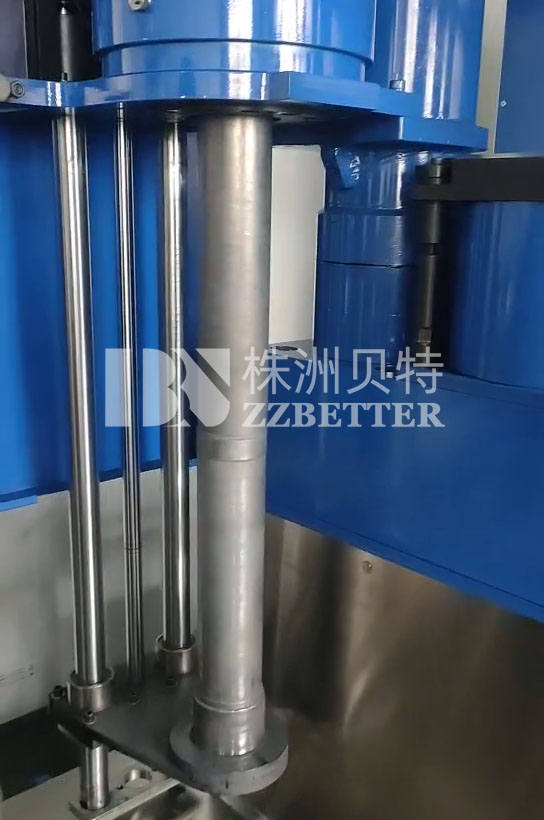

2. Extrusion Pressing

Ho tobetsa Extrusion ho ka sebelisoa ho hatella mekoallo ea tungsten carbide. Ts'ebetsong ena, ho na le mefuta e 'meli ea li-agent tse sebelisoang haholo. E 'ngoe ke cellulose, 'me e' ngoe ke parafine.

Ho sebelisa selulose joalo ka moemeli ho ka hlahisa li-bar tsa tungsten carbide tsa boleng bo holimo. Tungsten carbide powder e hatelloa sebakeng sa vacuum ebe e tsoa e sa khaotse. Empa ho nka nako e telele ho omisa mekoallo ea tungsten carbide pele o sintering.

Ho sebelisa boka ba parafine ho boetse ho na le litšobotsi tsa eona. Ha li-bars tsa tungsten carbide li tsoa, ke 'mele o thata. Kahoo ha ho nke nako e telele ho omella. Empa li-bar tsa tungsten carbide tse hlahisoang ka parafine kaha moemeli oa eona oa ho etsa li na le sekhahla se tlase se tšoanelehang.

3. Dry-bag Isostatic Pressing

Dry-bag isostatic pressing e ka boela ea sebelisoa ho tobetsa li-tungsten carbide bar, empa feela bakeng sa ba ka tlase ho 16mm bophara. Ho seng joalo, ho tla ba bonolo ho senya. Nakong ea khatiso ea isostatic ea mokotla o omileng, khatello ea ho theha e phahame, 'me mokhoa oa ho hatella o potlakile. Li-tungsten carbide bar ka mor'a hore mokotla o ommeng o hatelle isostatic o tlameha ho siloa pele o sintering. 'Me joale e ka sintered ka ho toba. Ts'ebetsong ena, moemeli oa ho etsa ke parafine kamehla.

Ho latela lihlahisoa tse fapaneng tsa carbide tse entsoeng ka samente, lifeme li tla khetha mekhoa e fapaneng ho netefatsa katleho ea tsona le boleng bo holimo ba lihlahisoa tsa tungsten carbide.

Haeba u thahasella li-rod tsa tungsten carbide 'me u batla boitsebiso bo eketsehileng le lintlha tse ling, u ka RE THUTA ka mohala kapa ka poso ka ho le letšehali, kapa U RE THUSE MAIL botlaaseng ba leqephe.