Qetella libopeho tsa Mill le Mathata Ho rarolla mathata

Qetella libopeho tsa Mill le Mathata Ho rarolla mathata

Ho na le mefuta e mengata ea litsila tsa ho qetela tsa tungsten carbide tse entsoeng ka lintlha tse fapaneng tse fapaneng ho u nolofalletsa ho khetha leloala le nepahetseng ho lumellana le thepa eo u sebetsang ho eona, le mofuta oa morero oo u tla o sebelisa. Sebopeho se seng le se seng sa leloala la pheletso se etselitsoe morero o itseng. Libopeho tse ling tse tloaelehileng tsa ho seha ke nko ea bolo, sekwere, radius ea sekhutlo le Chamfer. Litšobotsi tsa mofuta o mong le o mong oa ho qetela ke tse latelang:

Ball nose Mills e hlahisa pasa e chitja 'me e loketse mosebetsi oa 3D Contour Feeds and Speeds

Radius end mill e khothaletsoa haholo hobane e netefatsa ho itšeha ho sa feleng le ho tlosoa ha chip. Mathoko a radius a eketsa matla a sekhutlo mme a hlahisa radius e lakatsehang mme a fihlela litlhoko tse sebetsang tsa khatiso.

Chamfer end mill e tla theha ketso ea ho itšeha e thusang ho pshatla li-chips lisebelisoa tse ngata. Chamfering e lumella litekanyetso tse boima tsa phepo le tlhahiso e sebetsang haholoanyane. Boemo ba bona ba angled bo lumella chamfer, bevel, le likheo tse ling tse nang le angled ka thepa e kang aluminium, koporo, boronse, tšepe le tšepe.

Li-mill end Mills Hangata li bitsoa Flat End Mills, li sebelisoa bakeng sa lits'ebetso tse akaretsang tsa ho sila ho kenyelletsa slotting, profiling, plunge cutting, le milling square mahetla. Square End Mills e hlahisa bohale bo bohale botlaaseng ba li-slots le lipokothong tsa workpiece. Flutes holim'a e 'ngoe le e' ngoe ea lihlooho tsa ho itšeha tsa li-mill li tsamaisa li-chips hole le sesebelisoa ho thibela tšenyo ea leloala la ho qetela kapa mosebetsi. Li-mill end Mills li sebelisoa ho CNC kapa mechini ea ho sila ka letsoho.

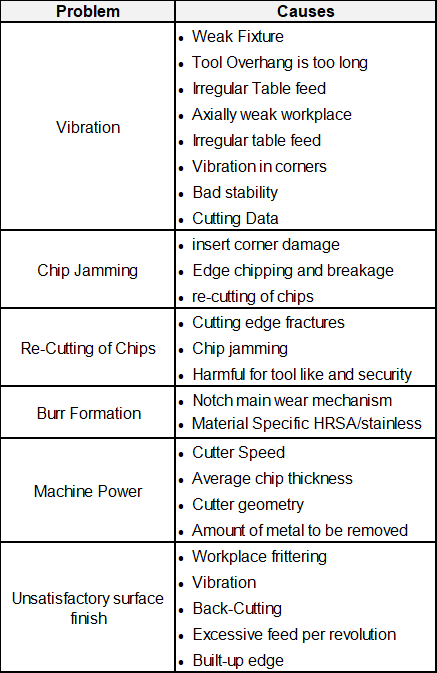

Hape ho na le tharollo ea mathata mabapi le mathata ao u ka kopanang le 'ona ha u sebelisa leloala la ho qetela:

Haeba u thahasella lihlahisoa tsa tungsten carbide 'me u batla boitsebiso bo eketsehileng le lintlha tse ling, u ka RE THUTA ka mohala kapa ka poso ka letsohong le letšehali, kapa U RE THUSE MAIL botlaaseng ba leqephe.