Likarolo le Lisebelisoa tsa likarolo tsa Carbide Wear

Likarolo le Lisebelisoa tsa likarolo tsa Carbide Wear

Likarolo tse hananang le ho roala tse entsoeng ka tungsten carbide e le lisebelisoa tse tala li ka bitsoa likarolo tsa moaparo oa carbide, tse nang le boima bo phahameng, khanyetso e matla ea ho roala, le lisebelisoa tse pharaletseng tsa indasteri. Ho hanyetsa ho apara ka mokhoa o babatsehang le ho thatafala ho phahameng ho li etsa hore li tšoanelehe bakeng sa ho etsa likarolo tsa mochine le ho hula lesela le nang le mocheso o phahameng oa mocheso, ho hanyetsa likhohlano, le ho hanyetsa kutu.

Lisebelisoa tsa likarolo tsa carbide

Likarolo tsa liaparo tsa tungsten carbide li na le letoto la ts'ebetso e ntle haholo, ho hanyetsa ho apara hantle, matla a phahameng le ho tiea, ho hanyetsa mocheso, le ho hanyetsa kutu, haholo-holo boima ba bona bo phahameng le ho hanyetsa ho apara hantle, ho fana ka tšehetso e matla ea sehlahisoa le ts'ebetso e babatsehang bakeng sa tlhahiso ea indasteri, ho thusa ho ntlafatsa. katleho ea tlhahiso le ho lelefatsa bophelo ba tšebeletso ea lisebelisoa.

1. E loketse ho etsa meqolo ea tšepe e entsoeng ka tšepe le meqolo e phahameng ea nickel-chromium ho lokisa li-cutters tse bōpiloeng.

2. E sebedisetsoa ho etsa lipoleiti tsa ho laolla, stamping die, mold convex, electronic level molding, and other stamping dies.

3. Ka pompong, compressor, le mixer, tungsten carbide seal e sebelisoa e le mochini oa ho tiisa holim'a metsi.

4. Likarolo tsa ho roala li-carbide li ka sebelisoa ka lesale la tšepe lefapheng la ho ohla le ho loha ho thibela menyenyetsi le ho falla ha li-enantiomers ho tloha ho potoloha ka lebelo le phahameng le ho lumella mochine hore o sebetse hantle.

Ke likarolo life tse sebelisoang hangata tsa carbide?

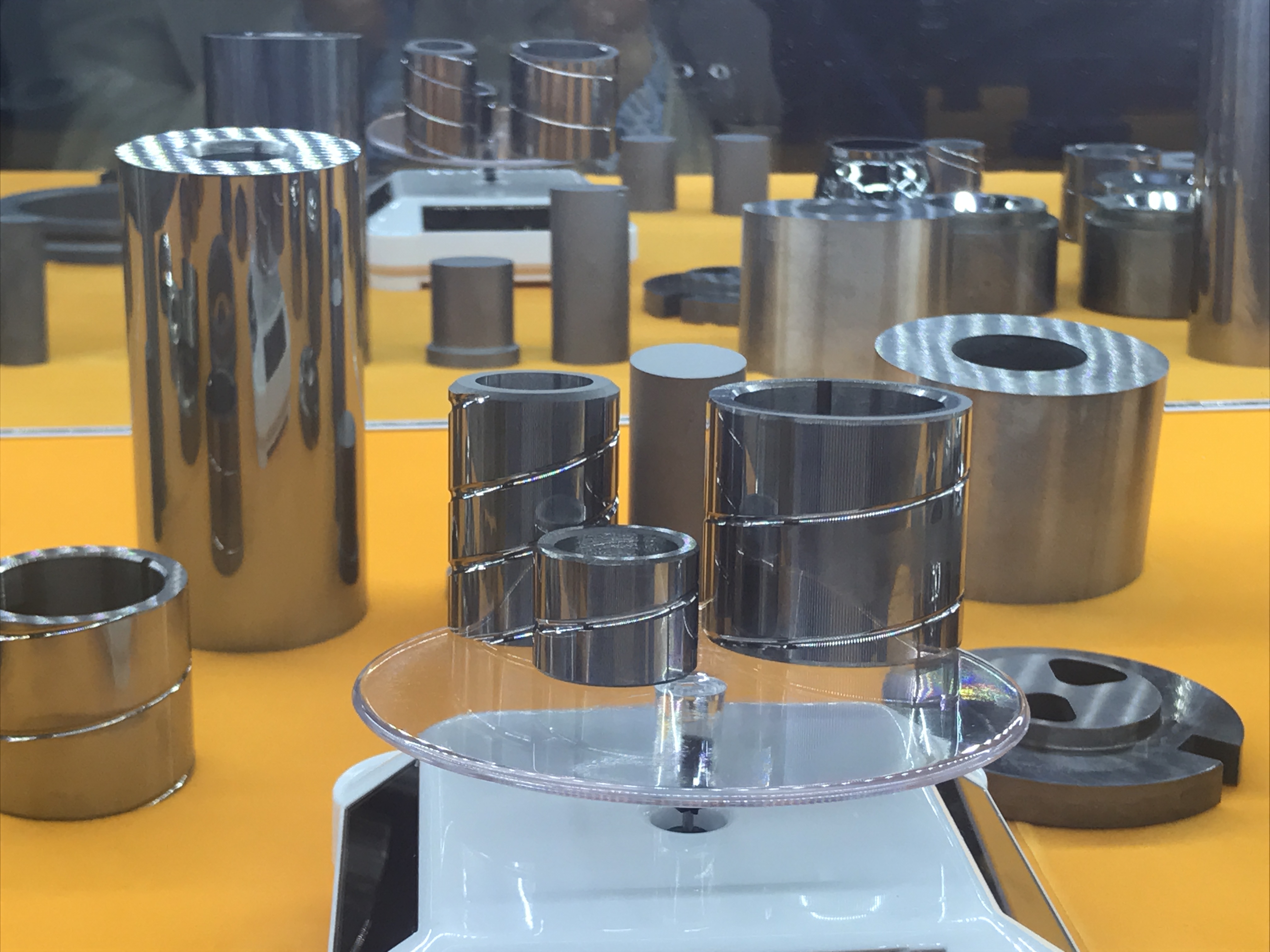

Lihlahisoa tsa Tungsten carbide tse sebelisoang e le likarolo tse manganga li kenyelletsa nozzle, seporo sa tataiso, plunger, tire anti-slip nail, garafo lehloa la lehloa, kharafu e fielang, selikalikoe sa rotary seal, mandrel e silang, likarolo tse fapaneng tsa pompo, likarolo tsa valve, litiiso, jj.

Likarolo tsa liaparo tsa Carbide li ka sebelisoa haholo joalo ka "carbide roller", "molding" e nepahetseng le hlobo ea optical, hlobo ea setempe, litšoantšo, lesale la tiiso, piston, koranta ea bearing, le welding e thata ka holim'a metsi, lisebelisoa tsa fafatsa, jj.

ZZBETTER e ikemiselitse ho fana ka lihlahisoa tsa carbide tse sebetsang hantle bakeng sa tlhahiso ea mochini oa indasteri. ZZBETTER e itšetlehile ka theknoloji e phahameng ea tlhahiso, lisebelisoa tsa tlhahiso ea litsebi, le lilemo tse fetang 20 tsa phihlelo, ho fa bareki lihlahisoa tsa boleng bo phahameng ba carbide ho latela litšoantšo le ho khetha thepa e phahameng ho eketsa litlhoko tsa tšebeliso ea bareki bakeng sa likarolo tsa ho apara carbide.

Haeba u thahasella lihlahisoa tsa tungsten carbide 'me u batla boitsebiso bo eketsehileng le lintlha tse ling, u ka RE THUTA ka mohala kapa ka poso ka ho le letšehali, kapa U RE THUSE MAIL botlaaseng ba leqephe.