Mokhoa oa ho Braze Tungsten Carbide Lisebelisoa tsa ho Seha

Mokhoa oa ho Braze Tungsten Carbide Lisebelisoa tsa ho Seha

Ho qhomisoa ha lisebelisoa tsa ho itšeha tsa carbide ho ama boleng ba sesebelisoa. Ho phaella tabeng ea hore na mohaho oa sesebelisoa o nepahetse le ho khethoa ha lisebelisoa tsa lisebelisoa ho loketse, ntlha e 'ngoe ea bohlokoa e itšetlehile ka ho laola mocheso oa ho chesa.

Nakong ea tlhahiso, ho na le mekhoa e mengata ea brazing bakeng sa lisebelisoa tsa ho itšeha ka tungsten carbide, 'me litšobotsi tsa bona tsa brazing le mekhoa ea bona le tsona li fapane. Sekhahla sa ho futhumatsa se na le phello e kholo ho boleng ba brazing. Ho futhumala ka potlako ho ka baka mapetsong le braze e sa lekaneng ho kenya carbide. Leha ho le joalo, haeba ho futhumatsa ho lieha haholo, ho tla baka oxidation ea welding surface, e leng se etsang hore ho fokotsehe ha matla a brazing.

Ha u khabisa lithulusi tsa ho itšeha, ho futhumatsa junifomo ea shank ea sesebelisoa le tip ea carbide ke e 'ngoe ea maemo a mantlha a ho netefatsa boleng ba brazing. Haeba mocheso oa mocheso oa ntlha ea carbide o phahame ho feta oa shank, solder e qhibilihisitsoeng e kolobisa carbide empa eseng shank. Tabeng ena, matla a brazing a fokotsehile. Ha ntlha ea carbide e kuta ka lehlakoreng la solder, solder ha e senyehe empa e arohane le ntlha ea carbide. Haeba lebelo la ho futhumatsa le potlakile haholo 'me mocheso oa toolbar o phahame ho feta oa ntlha ea carbide, ho tla etsahala ntho e fapaneng. Haeba ho futhumatsa ho sa tšoane, likarolo tse ling li khabisitsoe hantle, 'me likarolo tse ling ha li na brazed, e leng se fokotsang matla a ho roala. Ka hona, ka mor'a ho fihla mocheso oa brazing, ho ea ka boholo ba ntlha ea carbide, e lokela ho bolokoa metsotsoana e 10 ho isa ho e 30 ho etsa mocheso holim'a seaparo sa seaparo sa brazing.

Ka mor'a ho qhoqhoa, tekanyo ea ho pholile ea sesebelisoa e boetse e na le kamano e ntle le boleng ba brazing. Ha ho pholile, khatello e matla ea hang-hang e hlahisoa ka holim'a ntlha ea carbide, 'me ho hanyetsa ha tungsten carbide ho khatello ea maikutlo ho mpe haholo ho feta khatello ea khatello ea kelello.

Ka mor'a hore sesebelisoa sa tungsten carbide se be le brazed, se bolokoa se futhumetse, se pholile, 'me se hloekisoe ka sandblasting, ebe u hlahloba hore na carbide e kenya letsoho e tiisitsoe ka thata holim'a sesebelisoa, hore na ho na le khaello ea koporo, boemo ba carbide ke bofe. kenya sekotjana, le hore na seketsoana sa carbide se na le mapetsong.

Lekola boleng ba braze kamora ho chorisa bokamorao ba sesebelisoa ka lebili la silicon carbide. Karolong ea ntlha ea carbide, solder e sa lekaneng le mapetsong ha e lumelloe.

Sebakeng sa brazing, lekhalo le sa tlatsoang ka solder ha lea lokela ho ba kholo ho feta 10% ea bolelele bohle ba braze, ho seng joalo, e lokela ho rekisoa hape. Botenya ba lera la welding ha boa lokela ho feta 0.15 mm.

Hlahloba hore na boemo ba carbide e kenya ka har'a groove ea ho kenya welding e finyella litlhoko tsa tekheniki.

Tlhahlobo ea matla a brazing ke ho sebelisa ntho ea tšepe ho otla toolbar ka matla. Ha o otla, lehare ha lea lokela ho oela holim'a toolbar.

Carbide cutting tool brazing tlhahlobo ea boleng ke ho netefatsa bophelo ba tšebeletso ea lehare la carbide, hape ke tlhokahalo bakeng sa ts'ebetso e sireletsehileng.

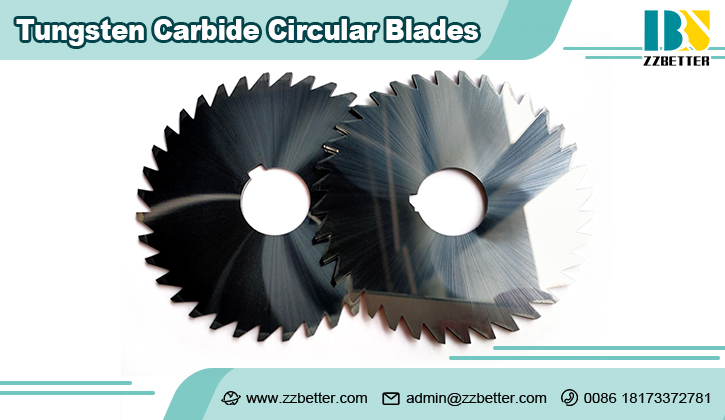

Haeba u thahasella lisebelisoa tsa ho seha li-tungsten carbide 'me u batla boitsebiso bo eketsehileng le lintlha tse ling, u ka RE THUTA ka mohala kapa ka poso ka ho le letšehali, kapa U RE THUSE MAIL botlaaseng ba leqephe.