Mokhoa oa ho Ntlafatsa Khanyetsano ea Liaparo tsa Carbide Wear?

Mokhoa oa ho Ntlafatsa Khanyetsano ea Liaparo tsa Carbide Wear?

Ts'ebetso ea moaparo oa tungsten carbide e angoa ke ts'ebeliso ea tikoloho le ts'ebetso ea alloy. Ho hanyetsa ho apara ho khethoa haholo-holo ke microstructure le metsoako ea lik'hemik'hale. Likarolo tse ka sehloohong tsa sebopeho sa carbide e entsoeng ka samente ke boholo ba lijo-thollo le karolo ea bonding. Ho hanyetsa ho apara ho boetse ho angoa ke lintho tse ekelitsoeng tse kang barium.

Tlhahisong ea indasteri, lisebelisoa tse ngata tsa bohlokoa tsa mochini le likarolo tsa tsona tsa mochini li maemong a thata, joalo ka lebelo le phahameng, mocheso o phahameng, khatello e phahameng, ho sebeletsa ho feta tekano, joalo-joalo, ka lebaka leo, ts'enyehelo ea likarolo tsa mochini e etsahala khafetsa ka lebaka la ho roala, ho bola le ho senya. oxidation, eo hangata e bakoang ke bokahodimo.

Mehato e sireletsang holim'a metsi e sebelisetsoa ho lieha le ho laola tšenyo, e fetohileng mokhoa o atlehang oa ho rarolla ho roala ha likarolo tsa mechine. Ka hona, ho amoheloa mekhoa e fapaneng ea abrasion holim'a likarolo tsa mochini, joalo ka plating, thermos, carburizing, nitriding, tšepe e kenang, ho fafatsa ka mocheso, holim'a holim'a metsi, ho roala le ho beha lesela le thata, boriti bo matla, jj.

Lefatše le sa tloaelehang le sebelisitsoe ka katleho karolong ea carbide wear. Ha matla le tšusumetso e matla e eketseha ka 10%, ho hanyetsa ho apara ha likarolo tsa carbide le hona hoa ntlafala.

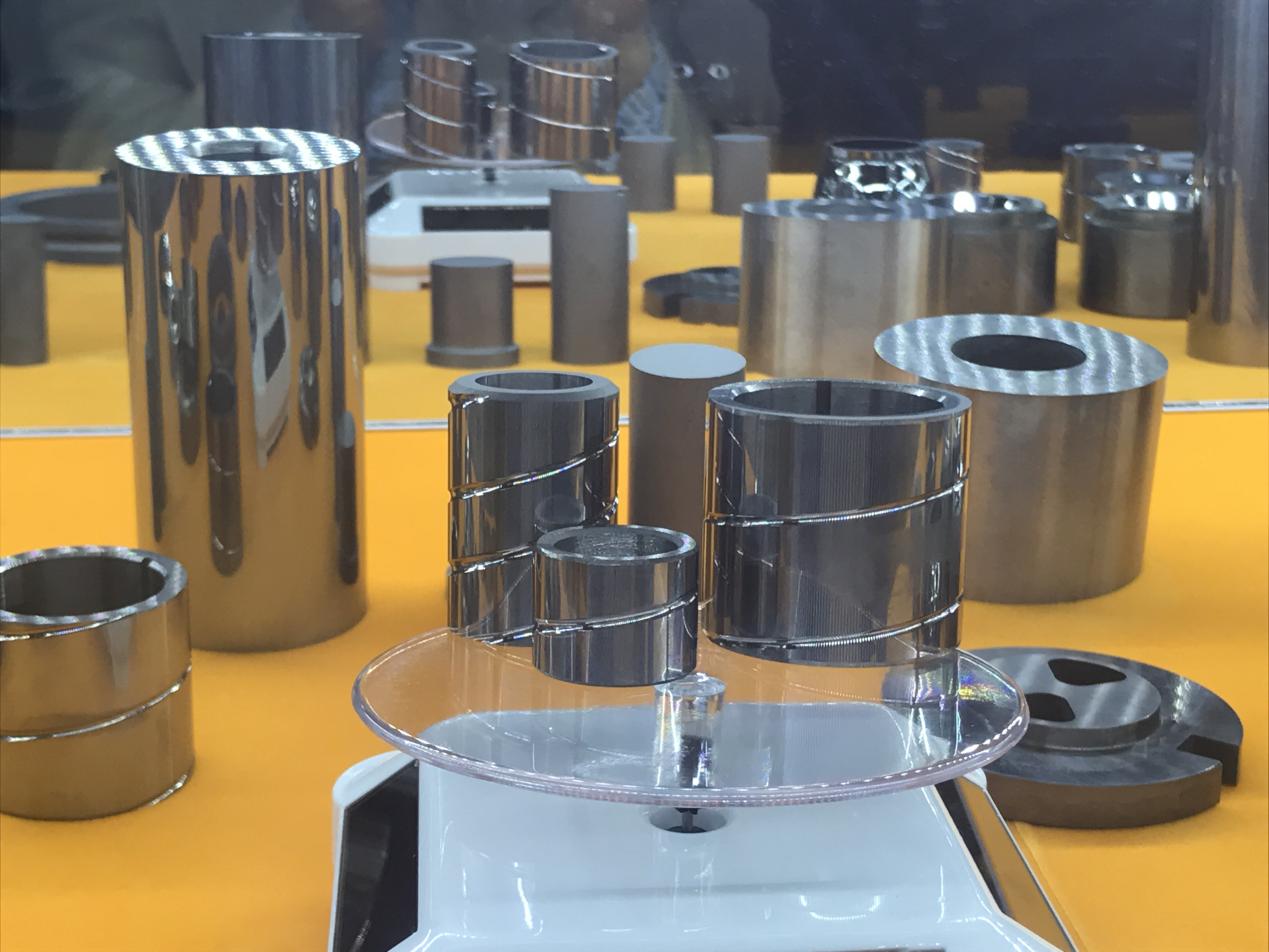

Mohlala, likarolo tsa hlobo tsa Tungsten carbide li na le ts'ebetso e ntle mme li sebelisoa haholo indastering ea ho lokisa likarolo tsa hlobo. E le ho eketsa boleng ba eona, ke habohlokoa ho ntlafatsa ho hanyetsa ha likarolo tsa hlobo ea tungsten carbide.

Ka kakaretso, mokhoa o sebetsang ka ho fetesisa le o otlolohileng oa ho ntlafatsa ho hanyetsa ha likarolo tsa hlobo ea tungsten carbide ke ts'ebetso ea plating ea titanium - bophelo ba holim'a metsi, ho thatafala, ho eketsa boleng le ho hanyetsa ho roala, ho hanyetsa kutu, joalo-joalo.

Bokaholimo ba boima bo nepahetseng bo bekhang bo koahetsoeng ka vacuum coefficient e ka ba le coefficient e tlase haholo ea likhohlano, e fokotsang matla a ho sebetsa. Ho hatakela ka setempe se batang le ho toroea sekoaelo se koahetsoeng ka vacuum ho ka fokotsa likhohlano, mongoo le ho roala haholo nakong ea ts'ebetso. Ka hona, e ka eketsa nako ea bophelo le ho fokotsa litšenyehelo haholo.

Melemo:

1. Fokotsa coefficient ea likhohlano, fokotsa matla a ho sebetsa, ho ntlafatsa ho thatafala ha holim'a metsi, le ho lelefatsa bophelo ba lefu haholo.

2. Ha ho sebelisoa lefu, bothata ba ho hlōleha kapele hangata bo rarolloa.

3. Etsa molemo ka ho fetisisa oa workpiece ho phetha karolo e feletseng.

4. Ho ntlafatsa ka matla boleng (joalo ka ho hlaka holim'a metsi, ho nepahala, joalo-joalo) le bophelo ba tšebeletso ea likarolo tsa hlobo, e le ho etsa hore ba bapale bokhoni ba lihlahisoa ka katleho.

Haeba u thahasella lihlahisoa tsa tungsten carbide 'me u batla boitsebiso bo eketsehileng le lintlha tse ling, u ka RE THUTA ka mohala kapa ka poso ka ho le letšehali, kapa U RE THUSE MAIL botlaaseng ba leqephe.