Mokhoa oa ho Weld Plow ea Lehloa ka Tungsten Carbide

Mokhoa oa ho Weld Plow ea Lehloa ka Tungsten Carbide

Keywords: meno a lehloa; tungsten carbide; kharafu ea lehloa; carbide e entsoeng ka samente

Sengoliloeng sena haholo-holo se hlalosa mokhoa oa meno a kharafu ea lehloa le tjheseletsa ea tungsten carbide. Taba ea pele, "square groove" bakeng sa ho kenya litšepe tsa carbide tse kentsoeng ka holim'a meno a kharafu a embryo, 'me khatello e thusang ea hydraulic e etsoa ka ho kenya lisebelisoa tsa hydraulic welding e le hore groove e kaholimo ho meno a kharafu. arc. Sebaka se ka tlaase sa arc groove se tlaase bohareng 'me se phahame ka mahlakoreng ka bobeli. Ka mor'a moo, tšepe e qhibilihisang e qhibilihisang carbide strip le leino la kharafu le se nang letho le kenngoeng 'meleng ho etsa meno a kharafu, ka mochini oa brazing o mahareng oa maqhubu bakeng sa welding.

meno a kharafu a lehloa a sebelisoa haholo ka pele ho sekoahelo sa lehloa sa lisebelisoa tsa kharafu, tse hlokang ho hanyetsa ho apara le ho bata. Meno a kharafu a teng a lehloa ka kakaretso a entsoe ka tšepe ea carbon, alloy steel kapa die steel, tse nang le ts'oaetso e mpe ea ho apara le tšusumetso e kholo bophelong ba tšebeletso. Carbide e na le boima bo phahameng ka ho fetisisa, 'me mokhoa o motle ka ho fetisisa oa ho apara oa thepa, o entsoeng ka hardness carbide le alloy, o na le khanyetso e phahameng ea ho apara, empa ho thata ho fokola,' me ts'ebetso ea welding e bonolo ho senya. Ka palo e kholo ea liteko, re fumane hore ho sebelisa mokhoa o tloaelehileng oa ho tjheseletsa ho tla baka deformation ea tšepe ea tšepe, ho phunyeha ha alloy, le mathata a mang.

Mehato ea ts'ebetso:

1. Seha poleiti e tloaelehileng ea tšepe ea carbon hore e be sebopeho sa lisebelisoa tse se nang letho tsa meno a kharafu ea lehloa.

2. Ka holim'a leino la lehloa le se nang letho, ho na le groove ea square groove bakeng sa ho kenya likotoana tsa carbide tse entsoeng ka samente.

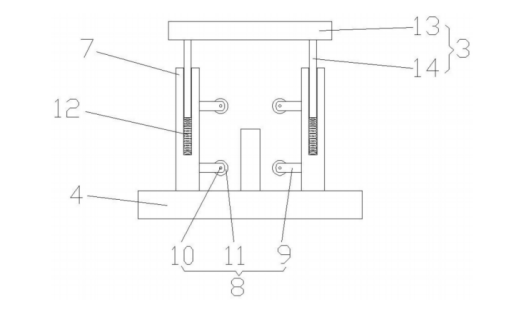

3. Etsa lisebelisoa tsa ho tjheseletsa likharafu tsa hydraulic, kenya garafo ea embryo ka har'a sesebelisoa sa welding sa kharafu sa hydraulic bakeng sa khatello ea haeteroliki e le hore groove e kaholimo ho garafo e embryo ke hydraulic arc groove, bokaholimo ba arc. groove e tlase bohareng mme e phahame ka mahlakoreng a mabedi a bokahodimo ba arc.

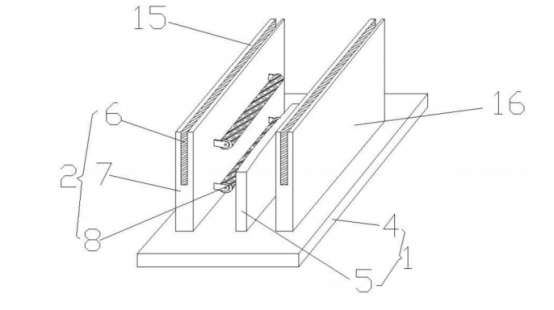

4. Eketsa tšepe ea ho tlatsa ka tlaase ho arc groove ka holim'a lisebelisoa tse se nang letho tsa leino la lehloa, ebe u kenya lesela la carbide le samente ka har'a arc groove, e le hore tšepe ea ho tlatsa e be teng pakeng tsa lesela le sirelelitsoeng la carbide le tlase. ea arc groove.

5. Mochini oa brazing oa maqhubu a mahareng o sebelisoa bakeng sa tjheseletsa, 'me mochini o entsoeng ka samente oa carbide o hokahane le lisebelisoa tse se nang letho tsa pola ea lehloa ka ho qhibilihisa tšepe ea brazing ho etsa leino la kharafu ea lehloa.

6. Kamora ho cheselletsa, pholisa meno a kharafu a cheselitsoeng mocheso oa kamore.

Qetello:

Ho rarolla mathata a deformation le alloy cracking pakeng tsa meno a kharafu le sekontiri se samente sa carbide ka mor'a ho tjheseletsa, moqapi ona o nka theknoloji ea "arc hydraulic welding" e ncha. Taba ea pele, groove ea lisekoere bakeng sa likhoele tsa carbide tse kentsoeng li entsoe ka holim'a lintho tse se nang letho tsa meno a kharafu, 'me khatello ea hydraulic e thusang e etsoa ke sesebelisoa sa ho tjheseletsa sa garafu meno a hydraulic. The square groove ka holim'a lehloa garafo garafo leino embryo e hydraulically thehoa ho ba arc groove.

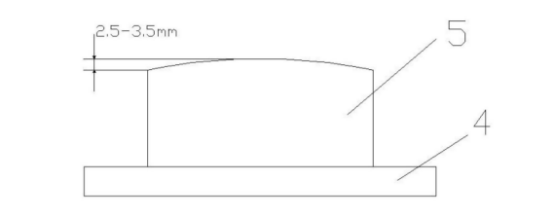

Sebaka se ka tlase sa arc groove ke sebaka sa arc se nang le mahlakore a tlaase a bohareng le a phahameng. Phapang pakeng tsa ntlha e tlaase ka ho fetisisa bohareng ba sebaka sa arc le ntlha e phahameng ka ho fetisisa mahlakoreng ka bobeli ke 2.5 ho 3.5mm. Ebe ka mochini o kopanyang oa maqhubu a mahareng bakeng sa tjheseletsa, ka tšepe ea brazing e qhibilihisang carbide strip le lisebelisoa tse se nang letho tsa leino tse kolobisitsoeng 'meleng ho etsa meno a kharafu.

Ka ts'ebetso ea welding ea arc hydraulic welding, palo ea deformation ea arc groove e ka laoloa ka nepo, e le hore boikaketsi ba hydraulic le khatello ea maikutlo ea kahare ea lehloa la leino la leino la lehloa le lesela le samente la carbide le ka thellana, 'me ka morao. deformation palo le tjheseletsa deformation palo ka offset mong le e mong tse ling tse, kahoo haholo fokotsa monyetla oa deformation ea lehloa mohoma kharafu leino le tjheseletsa cracking kgonego ya carbide samente. Ka nako e ts'oanang, e boetse e ntlafatsa haholo ho bata, ho hanyetsa ho apara, le bophelo ba tšebeletso ea meno a kharafu.

Thepa e entsoeng ka samente e entsoeng ka carbide e cheselitsoeng karolong e ka pele ea meno a kharafu ke lisebelisoa tsa alloy tse entsoeng ka tšepe e hanyetsanang le tšepe e kopantsoeng ka mokhoa oa metallurgy oa phofo, o nang le boima bo phahameng, ho hanyetsa ho apara, matla le ho tiea, ho hanyetsa mocheso, ho hanyetsa kutu le letoto la lisebelisoa. thepa e babatsehang, haholo-holo boima ba eona bo phahameng le ho roala ho hanyetsa, esita le mocheso oa 500 ℃ ha e le hantle ha o fetohe.

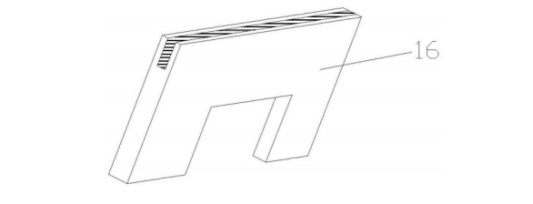

Setšoantšo sa 1

Setšoantšo 2

Setšoantšo 3

Setšoantšo 4

Tse ling tsa litaba tsa sengoloa sena li qotsa le ho fetolela ho tsoa tlalehong ea Sechaena ea Patent ea Invention. Ke tšepa hore boitsebiso bona bo na le thuso ho uena, 'me u amohelehile ho siea maikutlo le lipotso tsa hau ka tlase. ZZBETTER e fana ka lihlahisoa tse fapaneng tsa tungsten carbide ka litheko tse nepahetseng. Re emetse lipatlisiso tsa hau haeba u hloka ntho leha e le efe e amanang le carbide e entsoeng ka samente, feela u re fe litšoantšo tsa hau, re ka u etsetsa e nepahetseng.