Taolo ea boleng ba li-cutters tsa PDC

Taolo ea boleng ba li-cutters tsa PDC

Liseha tsa PDC li entsoe ka polycrystalline Diamond layer le carbide substrate. Liseha tsa PDC li boetse li bitsoa Polycrystalline Diamond Compact cutters, e leng mofuta oa thepa e thata haholo. Tšebeliso ea li-cutters tsa polycrystalline diamond compact (PDC) li atile haholo matsatsing ana ka lebaka la ts'ebetso ea tsona e phahameng le ho tšoarella libakeng tse thata.

Lintho tsa bohlokoa haholo bakeng sa li-cutters tsa PDC ts'ebelisong ea ho cheka sebakeng sa oli ke boleng le botsitso. Ke lumela hore bohle ba tla lumela. Empa mokhoa oa ho laola boleng?

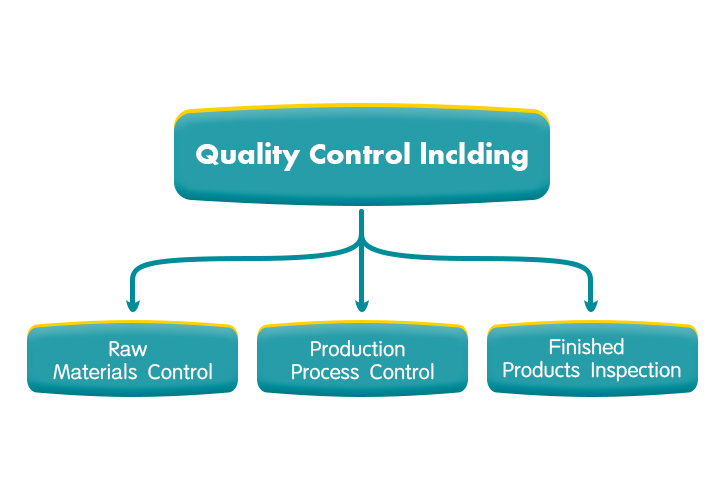

Ho etsa bonnete ba hore karolo e 'ngoe le e' ngoe ea PDC cutter e tla ho ZZKHABANEmatsoho a moreki a nang le boleng bo holimo, ZZKHABANEe thehile mokhoa o tiileng oa taolo ea boleng, ho kenyelletsa taolo ea thepa e tala, taolo ea ts'ebetso ea tlhahiso, le taolo ea lihlahisoa tse felileng. Mosebeletsi oa rona o koetlisitsoe haholo ebile o hloahloa haholo ebile o inehetse. Sehahi se seng le se seng sa PDC se hahiloe ka basebetsi ba koetlisitsoeng haholo 'me khatello e laoloa ka mechine ea khatiso nakong ea sintering.

Taolo ea boleng ba PDC cutter:

1. Lisebelisoa tse so ntlafatsoe

2. Mokhoa oa tlhahiso

3. Tlhahlobo ea lihlahisoa tse felileng

1. Taolo ea thepa e tala

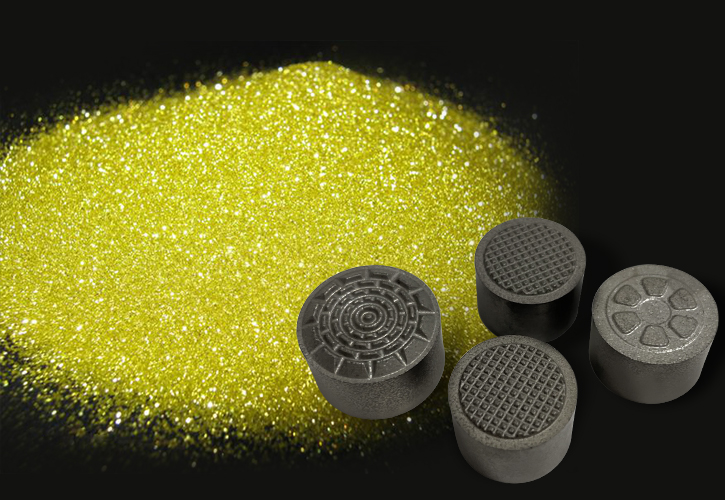

1.1 Bakeng sa ho etsa kopo ea ho cheka sebakeng sa oli ea PDC re sebelisa daemane e tsoang kantle ho naha. Re boetse re tlameha ho e pshatla le ho e bōpa hape, ho etsa hore boholo ba likaroloana bo tšoane. Re boetse re hloka ho hloekisa thepa ea daemane.

1.2 Re sebelisa Laser Particle Size Analyzer ho sekaseka kabo ea boholo ba karoloana, bohloeki le boholo ba beche ka 'ngoe ea phofo ea daemane.

1.3 Bakeng sa substrate ea tungsten carbide re sebelisa sehlopha se nepahetseng se nang le khanyetso e phahameng.

2. Mokhoa oa tlhahiso

2.1 Re na le basebetsi ba litsebi le lisebelisoa tse tsoetseng pele ho hlahisa li-cutters tsa PDC

2.2 Nakong ea tlhahiso re tla hlahloba mocheso le khatello ka nako ea sebele le ho fetola nako. Mocheso ke 1300 - 1500℃. Khatello ke 6 - 7 GPA. E tobetsa HTP.

Bakeng sa ho hlahisa karolo e le 'ngoe ea PDC Cutters e tla hloka metsotso e ka bang 30 ka kakaretso.

Bakeng sa sehlopha se seng le se seng sa li-cutters tsa PDC, sengoathoana sa pele se bohlokoa haholo. Pele ho tlhahiso ea bongata, re tla hlahloba sekhechana sa pele ho bona hore na se kopana le litlhoko tsa moreki bakeng sa boholo le ts'ebetso.

3.Tlhahlobo ea lihlahisoa tse felileng

Ho etsa bonnete ba hore li-cutters tsohle tsa PDC lia tšoaneleha ebile li tsitsitse, ha rea lokela ho laola feela tlhahlobo ea thepa e tala le taolo ea phallo ea tlhahiso le ntlafatso ea mahlale, hape re tlameha ho ikemisetsa ho aha laboratori e nang le lisebelisoa tse tsoetseng pele tsa liteko ho etsisa maemo a ho cheka sebakeng sa oli le ho etsa liteko tsa li-cutters tsa PDC fekthering. pele e isoa ho bareki ba rona.

Bakeng sa taolo ea sehlahisoa se felileng re tla etsa ho tsoa likarolong tse ka tlase:

Tlhahlobo ea boholo le ponahalo

Ho laola mefokolo ea ka hare

Teko ea ts'ebetso

3.1 Tlhahlobo ea boholo le ponahalo:bophara, bophahamo, botenya ba daemane, chamfer, boholo ba geometri, crack, letheba le letšo, jj.

3.2 Ho laola mefokolo ea ka hare

Bakeng sa taolo ea bokooa ba ka hare re tla sebelisa lisebelisoa tsa tlhahlobo tse tsoetseng pele tsa C-san tse tsoang kantle ho naha. Bakeng sa li-cutters tsa PDC tse kentsoeng ka oli re tlameha ho lekola likotoana tsohle.

Ka sistimi ea C-scanning, leqhubu la ultrasonic le ne le ka phunyeletsa lera la PDC mme la bona ho putlama ha eona kapa bofokoli ba cavity. Sistimi ea C-scanning e ka fumana boholo le boemo ba likoli 'me ea li bontša skrineng sa PC. Ho tla nka metsotso e ka bang 20 ho etsa tlhahlobo ea nako e le 'ngoe.

3.3 Teko ea sampole ea ts'ebetso ea PDC Cutter:

apara khanyetso

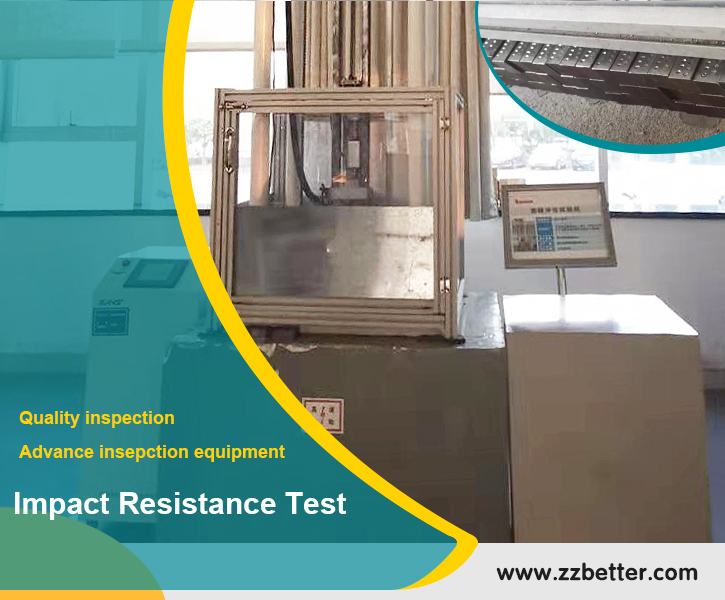

khanyetso ea tšusumetso

botsitso ba mocheso.

3.3.1 Wear Resistance Testing:ka ho lekanya hore na ke litekanyo tse kae tse lahlehileng ka mor'a hore li-cutters tsa PDC li sila granite ka nako e itseng, re fumana tekanyo ea ho senyeha. Ke tahlehelo e kholo lipakeng tsa li-cutters tsa PDC le granite. Ha karo-karolelano e phahame, ho tla ba le khanyetso e eketsehileng ea PDC Cutters.

3.3.2TšusumetsoTeko ea Resistance:Re boetse re e bitsa Teko ea Boima ba Boima, re sebelisa lesela le otlolohileng bophahamong bo itseng le thetheha holim'a profil ea PDC Cutter, hangata e nang le slide e itseng (15-25 degree). Boima ba lathe ena e otlolohileng le bophahamo ba eona e seng e setiloe li ka bontša hore na sehahi sena sa PDC se ka hanana le tšusumetso e kae.

3.3.3 Teko ea Thermal Stability:E reretsoe ho hlahloba hore na PDC Cutters e tsitsitse ka mocheso o lekaneng tlas'a maemo a phahameng a mocheso a sebetsang. Ka laboratoring, re beha li-cutters tsa PDC tlas'a 700-750℃ka metsotso e 10-15 'me u hlahlobe boemo ba lera la daemane ka mor'a ho pholile ha tlhaho moeeng. Hangata ts'ebetso ena e ne e tla tsamaisana le khanyetso e 'ngoe ea ho roala le ho hanyetsa tšusumetso ho bapisa boleng ba PDC cutter pele ho tlhahlobo le kamora tlhahlobo.

Rea u amohela ho latela leqephe la khampani ea rōna:https://lnkd.in/gQ5Du_pr

Ithute haholoanyane:WWW.TŠEBELETSO.COM