Ho tšoarella ha leqhubu la carbide cumarifeier cumarifier

Ho tšoarella ha leqhubu la carbide cumarifeier cumarifier

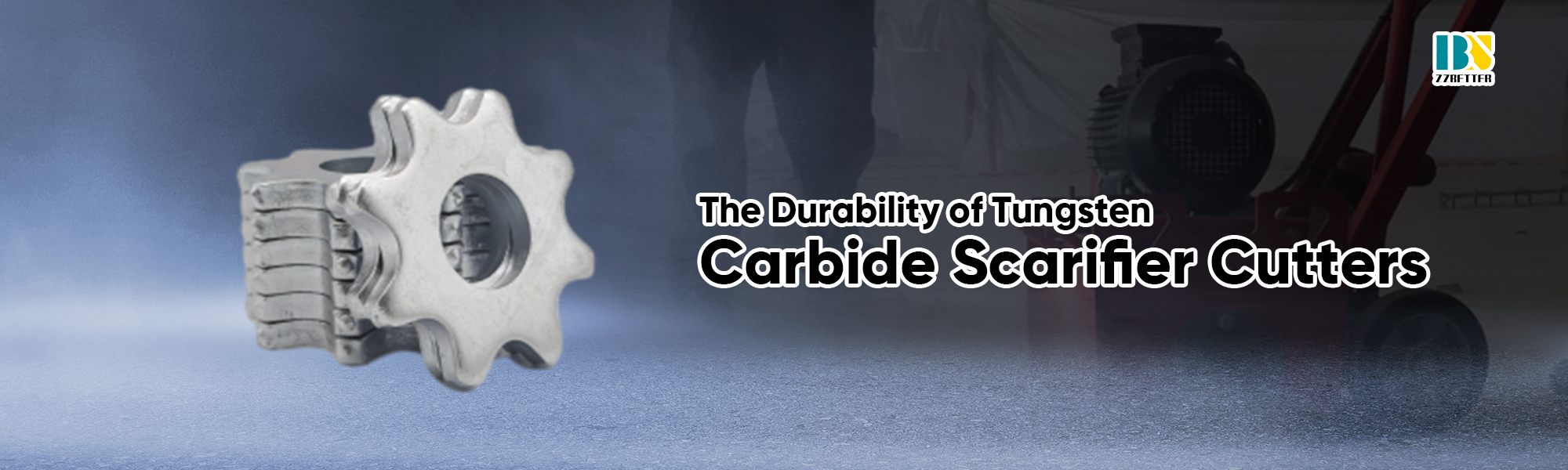

Tukten Carbide Cruters Cuterters Cumarier e tummeng ka ho tšoarella ha bona e ikhethileng, e ba etsang khetho e ratoang litoreng tsa tlhokomelo ea kaho le tsa tsela. Ho phela nako e telele le ho tiisa ha libaka tsena li ka hlahisoa ka matla a ikhethang a kobo ea tungsten, e leng motsoako o kopanyang tungnsten le khabone. Ho utloisisa lintlha tse tlatsetsang ho se tšoarelle ha makhulo ho ka thusa litsebi hore li etse liqeto tse tsebisoang le ho ntlafatsa ts'ebeliso ea tsona.

Ntlha e ka sehloohong e ka morao ho tšoarella ha matloana a tungsten cartifier ke ho ba thata ka tlhaho ea carbide. Tungas carbide ke e 'ngoe ea thepa e thata ka ho fetisisa e fumanehang, ea bobeli ho ea ho Diamond. Botemebe bona bo feteletseng bo lumella ba khaolang ho boloka matla a ho hloka le bohale le kamora ho sebelisoa haholo. Ho fapana le ho ts'oaroa ha tšepe e lerootho kapele, li-cutlesten cutters tsa carbide li ka mamella ho roala le ho tabosa ts'ebetso e sa fetoheng nako e telele.

Karolo e 'ngoe ea bohlokoa ea hore motho ea tšoarellang oa carbide ea tungsten ke khanyetso ea eona e phahameng ea ho tlōla. Hangata li-changters tse sa tsitsang li pepesetsoa lisebelisoa tse bolaeang tse kang konkreite, asphalt le likano tse fapaneng. Ho hanyetsa ha boima ba Carbision ho bolela hore li-churter li ka tlosa lisebelisoa hantle ntle le ho senya kapele. Khanyetso ena ha e felise bophelo ba ba kutu empa e boetse e ntlafatsa ts'ebetso ea bona, joalo ka metsamao e bohale e bolokiloe nako e telele, e fokotsa khafetsa, e khutlisetsa khafetsa.

Hlahloba carbide le eena o bontša botsitso ba botsitso ba mollo. Ho hlophisoa hohle le ho lokisa tsela hangata ho hlahisa mocheso oa bohlokoa ka lebaka la likhohlano pakeng tsa likheo le thepa e ntle. Metsoako e tšohileng ea setso e entsoeng ka tšepe e ka lahleheloa ke mathata 'me e se e sebetse ka lithemparetjha tse phahameng. Ho fapana le hoo, carbide carbide e boloka thata le ho senyeha le ka tlasa lithemparetjha tse phahameng. Ho tsitsa hona ho tsitsang ho tiisa hore li-changters tsa carbide li ka etsoa khafetsa maemo a bona.

Ho thata ho nka thata ke koloi e 'ngoe ea bohlokoa. Le hoja ho le thata, ho tlameha ho ba le lintho tse tsebang ho ba le tšusumetso le ho makala ntle le ho robeha. Leraba la tungns le kopanya ho ba le mathata, ho lumella likhetla tse se nang sekoli ho hana ho chechisa kapa ho likoloha nakong ea ts'ebetso e boima. Motsoako ona oa thepa o bohlokoa haholo bakeng sa lits'ebetso tse amanang le libaka tse thata le tse sa lekanang, moo ho sa tsotelleng ho bohlokoa.

Mokhoa oa ho etsa lihlahisoa oa carbide changter changes hape o phetha karolo ea bohlokoa ha a tšoarella borapeling ba bona. Mokhoa o tsoetseng pele tlhahiso, joalo ka phofo ea metallirgy, e sebelisoa ho theha li-fretter tsena. Ts'ebetso ena e kenyelletsa ho tobetsa leqhubu la carbime e hatellang ka sebopeho se lakatsehang ebe e e silafatsa ka lithemparetjha tse phahameng. Phello ke lisebelisoa tse teteaneng le tse tšoanang ka thepa e ntlafalitsoeng. Taolo ea boleng le boleng ho tlhahiso e tiisa hore ho tsoaloa ka mokhoa o hlakileng ho kopa litekanyetso tse hlokahalang bakeng sa ho tšoarella le ho sebetsa.

Mekhoa ea tlhokomelo ea tlhokomelo e ama ho tšoarella ha li-carbide cubiier changters. Tlhahlobo kamehla, ho hloekisa le ho boloka ka nepo ho ka eketsa bophelo ba likheo. Ka ho sebetsana le matšoao a ho roala kapa ho senya, bo-ralitiki ba ka thibela litaba tse nyane mathateng a maholo. Ntle le moo, u sebelisa li-chorter ho latela moetsi oa moetsi le ho li chesa ka lisebelisoa tse rarahaneng ho ka ntlafatsa ts'ebetso ea bona le ho phela bophelo bo bolelele.

Qetellong, ho tšoarella ha leqhubu la carkide le boima ba ho hanyetsa lintho tse ikhethang tsa lintho tse ikhethileng, ho tsitsipana le ho tsitsipana le ho tsitsipana le ho tsitsipana le ho tsitsipana le ho tsitsa Matlotlo ana, a kopantsoeng le mekhoa e tsoetseng pele ea tlhahiso le mekhoa e nepahetseng ea ho lokisa le ho tiisa hore ho na le litšila tse se nang kelello le tse telele. Bakeng sa litsebi tsa ho hlokomela le ho lokisoa ke tseleng, tsetsetse liketsaneng tsa cutasten cumarizer li fetotsoe mererong e ntlafalitsoeng ea ho itukisetsa le ho lokisa le ho lokisa. Kutloisiso le ho thusa ho tšoarella ha mathata ana ho ka matlafatsa katleho le ho tsitsa tsa mesebetsi e mengata ea kaho ea kaho.