Theknoloji ea Tlhahiso ea Hard Alloy

Theknoloji ea Tlhahiso ea Hard Alloy

Motsoako o thatake mofuta oa thepa e thata e entsoeng ka tšepe e thata ea refractory le tšepe e kopantsoeng; li-alloys tse thata, ke lisebelisoa tse thata tse nang le khanyetso e phahameng ea ho apara le ho tiea, tse hlahisoang ke metallurgy ea phofo; ka lebaka la ts'ebetso ea eona e ntle haholo, carbide e entsoeng ka samente e sebelisoa haholo ho machining, likarolo tse sa sebetseng, merafo, ho cheka ha geological, ho rafa oli, likarolo tsa mochini le masimo a mang.

Theknoloji ea Tlhahiso ea Litšepe Tse Thata e sebetsana le theknoloji ea tlhahiso le lipatlisiso tsa sebopeho le thepa ea 'mele ea litšepe tse thata. E 'ngoe ea lintlha tsa bohlokoa tsoelopeleng ea tekheniki ke tlhahiso ea naha ea litšepe tse thata. Ntlafatso le kenyelletso ea litšepe tse thata tse sebetsang hantle haholo li netefatsa hore tlhahiso ea basebetsi e tla eketseha indastering ea tšepe, ea merafo, ea oli le ea mashala.

Ts'ebetso ea tlhahiso ea carbide e entsoeng ka samente e tjena: ho lokisetsa motsoako, ho hatella le ho etsa, ho sintering. Ho na le mekhoa e 3 ka kakaretso.

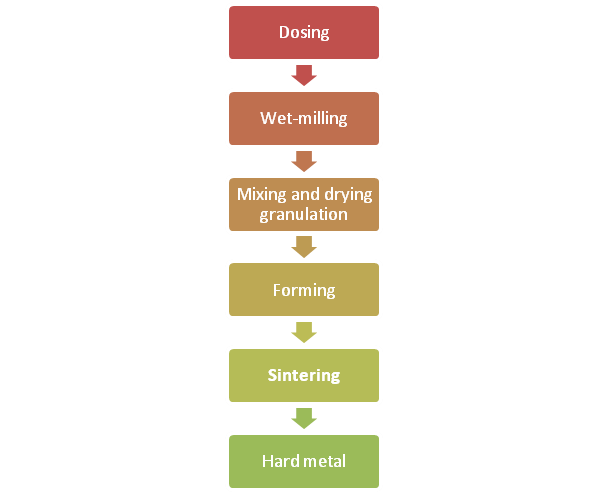

Chate e phallang ea ts'ebetso ea tlhahiso ea alloy e thata

Lisebelisoa tse tala le li-additives tse nyenyane tse hlokahalang li lekanngoa le ho kenngoa ka har'a leloala la bolo kapa leloala le susumetsang. Leloaleng la bolo, lisebelisoa tse tala li hloekisoa le ho ajoa ka ho lekana. Ka mor'a ho fafatsa ho omisa le ho sefa ho sisinyeha, motsoako o nang le litlhoko tse itseng tsa sebopeho le boholo ba likaroloana o etsoa ho finyella litlhoko tsa ho hatisa ho theha le ho sintering. Ka mor'a ho tobetsa le ho sintering, likheo tse thata tsa alloy lia lokolloa 'me li phuthetsoe ka mor'a tlhahlobo ea boleng.

Litšepe tse thata

Mokhoa oa ho sebetsa oa carbide e thata e entsoeng ka samente:

1. Ts'ebetso ea khoele ea kahare le kantle: ts'ebetso ea likhoele tsa carbide e lokela ho sebetsoa ka ho sila likhoele, e ke ke ea sebetsoa ka kotloloho ka lipompo tsa screw.

2. Ts'ebetso ea groove e ka hare: molamu oa ho sila oa daemane o lokela ho khethoa, 'me palo ea ho khaola nako le nako e laoloa ho ba hoo e ka bang 20 ho 30 um. Phetoho e khethehileng e lokela ho etsoa ho ea ka melemo le melemo ea molamu oa ho sila oa daemane.

3. EDM

4. Ts'ebetso ea welding: brazing, silver welding processing

5. Ts'ebetso ea ho sila: ho sila ho se nang setsi, ho sila ka hare, ho sila ka holim'a metsi, ho sila lisebelisoa, lebili la ho sila ka kakaretso ke lebili la ho sila la taemane, khetho e khethehileng ho itšetlehile ka litlhoko tsa ts'ebetso.

6. Ts'ebetso ea Laser: ho etsoa ha laser cutting, ho phunya ho fumaneha, empa botenya ba ho itšeha bo thibetsoe ke matla a lithibelo tsa mochine oa laser.

Haeba sehlahisoa sa hau sa tungsten carbide se le lerootho kapa "se koahetsoe", ha ho hlokahale hore u reke sehloekisi sa mabenyane se turang ho khantša le ho bentša mabenyane a hao a tungsten. Motsoako o bonolo oa metsi a sesepa le lesela le hloekileng ke tsona feela lintho tseo u li hlokang ho hloekisa tšepe ena e thata, e manganga. Hape, silicon carbide e molemo ka ho fetisisa bakeng sa ho chorisa carbide.

Haeba u thahasella lihlahisoa tsa tungsten carbide 'me u batla boitsebiso bo eketsehileng le lintlha, u ka khonaITEANYE LE RONAka mohala kapa poso ka letsohong le letšehali, kapaRE THUSOE MOKELEbotlaaseng ba leqephe lena.