Tungsten Carbide Studs Bakeng sa HPGR ke Life?

Tungsten Carbide Studs Bakeng sa HPGR ke Life?

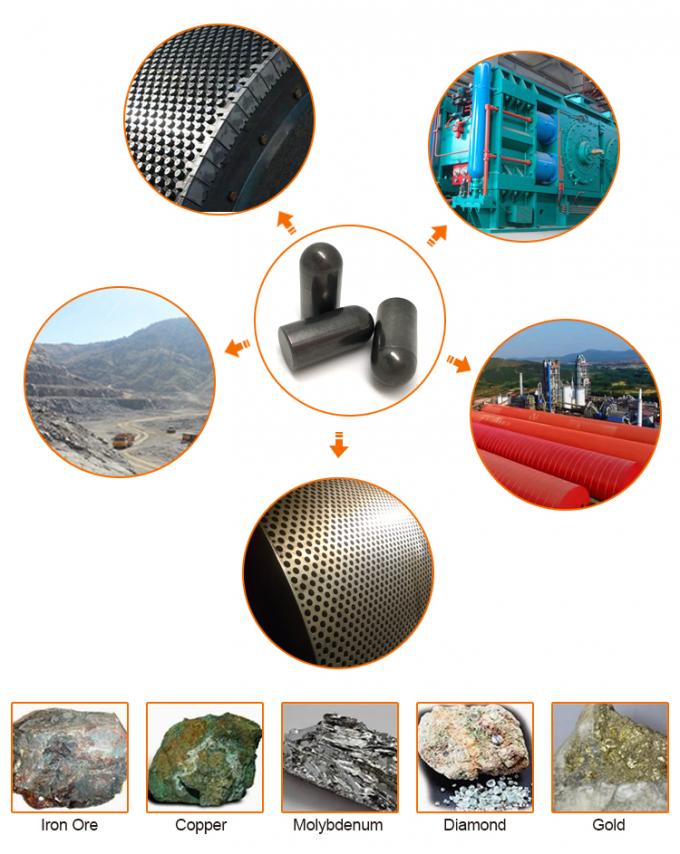

Li-tungsten carbide studs li boetse li bitsoa cemented carbide studs, li-buttons tsa carbide, le malebela a carbide, tse sebelisoang haholo bakeng sa lirolara tse silang tse nang le khatello e phahameng. Li-studs tsa carbide li sebelisoa bakeng sa ho sila rolara e nang le khatello e phahameng bakeng sa ho pshatla thepa e tala ea samente, clinker, ore ea tšepe, koporo, taemane le quartz. Nako ea bophelo e ka fihla lihora tse 8000-30000 ho latela limaraka tse fapaneng ka lits'ebetso tse fapaneng.

Li-studs tsa carbide tse kentsoeng e le karolo ea mantlha ea vertical impact crusher (thepa ea sandstone) li sebelisoa haholo merafong, lehlabatheng le lehlohlojaneng, samente, metallurgy, boenjiniere ba motlakase oa metsi, le liindasteri tse ling, tse kopang lihlahisoa ho mamella ts'ebetso ea lebelo le holimo le khanyetso e matla ea ho apara. , 'me ho sebelisa carbide e entsoeng ka samente ke khetho e nepahetseng. High-Pressure Grinding Roller ke sesebelisoa sa ho silakanya se baballang matla sa mahlale a macha. Ts'ebetso e phahameng ea carbide stud e lelefatsa bophelo ba High-Pressure Grinding Roller. ZZBETTER e fana ka li-studs tsa carbide tsa boleng bo botle tse nang le khanyetso e ntle ea ho roala le matla a phahameng a khatello, a ka khotsofatsang litlhoko tsa maemo a fapaneng.

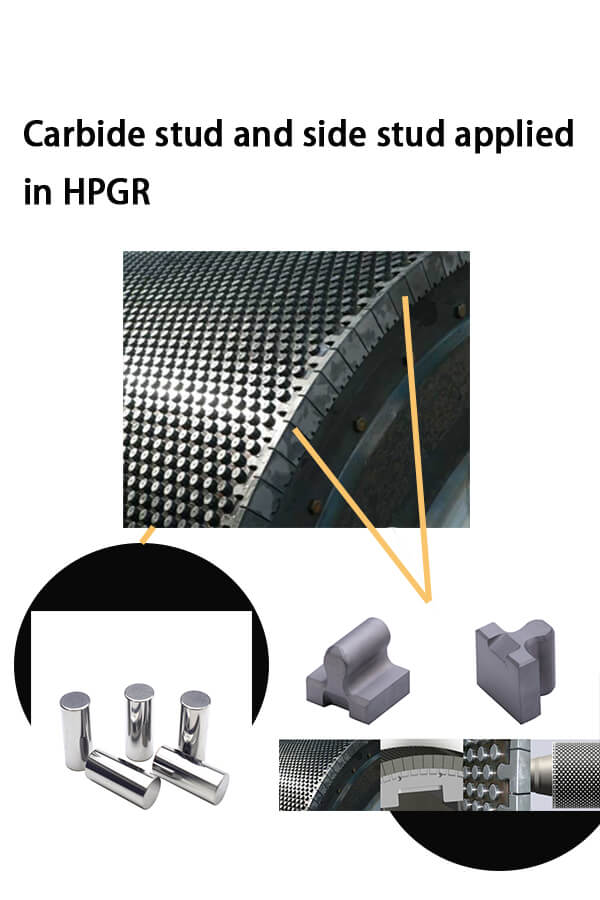

Ho na le mefuta e meraro ea mantlha ea likarolo tsa mantlha tsa HPGR: PTA layer roller surface, centrifugal casting composite roller surface, le stud roller surface. Bothata ba mefuta e 'meli ea pele ke hore sebaka sa marang-rang se tla ba le tšusumetso e matla ka lebaka la ho kopana ka ho toba ha moqolo ka thepa e tlas'a ketso ea matla a matla a extrusion (ka kakaretso 50-300MPa). Lijo-thollo le liforo tsa abrasive lia apara, 'me ka nako e ts'oanang, bokaholimo ba rolara bo tla hlahisa likoting tsa ho penya. Likoti tsena tse bokelletsoeng li tla baka mokhathala oa thepa ea holim'a roller, e amang haholo ts'ebetso e tloaelehileng ea lisebelisoa.

The stud roller holim'a 'mele oa motheo o entsoe ka tšepe ea alloy e matla, e nang le boima bo phahameng ka mor'a ho tima le ho halefa. Lera le sa tsitsang le entsoe ka li-tungsten-cobalt hard alloy studs le tse kentsoeng 'meleng. Ka kakaretso, ho fihla ho HRC67 kapa holimo, ho thatafala ho phahame haholo ho feta sebaka sa PTA layer roller le centrifugal casting composite roll surface. Matrix a holim'a stud roller e ka sireletsoa ke lesela la thepa le entsoeng. Tungsten carbide studs roller e na le bophelo ba ts'ebeletso nako e fetang makhetlo a 6 ho feta ea bokaholimo ba lirolara, e ka bolokang matla, ea sireletsa tikoloho, ea eketsa katleho ea mosebetsi le litšenyehelo tse tlase.

Likarolo tsa theknoloji ea tlhahiso ea li-studs tsa carbide bakeng sa HPGR:

1. Hemispherical ho sireletsa li-studs ho senngoa ke khatello ea maikutlo.

2. Mehato e chitja e sireletsa li-studs hore li se ke tsa senyeha nakong ea tlhahiso, lipalangoang, instolmente le tšebeliso.

3. HIP sintering etsa bonnete ba e ntle compactness le phahameng toughness bakeng sa lihlahisoa.

4. Theknoloji e khethehileng ea ho felisa khatello ea kelello ka mor'a ho sila holimo le ho eketsa boima ba holim'a metsi.

5. Setlolo se sebelisoa holim'a lihlahisoa ho qoba oxidization.

Lisebelisoa tsa carbide tsa ZZBETTER bakeng sa HPGR

-100% lisebelisoa tse tala tsa moroetsana, thepa ea lik'hemik'hale e tsitsitseng, bophelo bo bolelele ba ho sebetsa.

- Ho thatafala ho phahameng, ho tiea ho hotle, ho hanyetsa ho apara hantle.

- Mefuta e fapaneng ea boholo le mefuta e felletseng ea fumaneha

- Lihlahisoa li ka etsoa ho latela tlhoko

Ho paka lithupa tsa rona tsa carbide bakeng sa HPGR

mohato 1, phuthetsoe carbide stud ka pampiri ho qoba carbide stud pins ho robeha

mohato oa 2, kenya carbide stud pins ka har'a lebokose le lenyenyane la lebokose

mohato oa 3, kenya lebokose le ka hare ka lebokoseng le ka ntle 'me u tlatse lebokose ka polasetiki e foamed

mohato oa 4, phuthela lebokose ka tepi ea ho paka

Re u khothalletsa hore u sebelise li-studs tsa rona tsa carbide bakeng sa lirolara tsa ho sila tse nang le khatello e phahameng, kaha re na le phihlelo e ngata 'me re lula re fetola le ho ntlafatsa mekhoa.